A high frequency matching method for mhz level beam cutter

A flow cutter and high-frequency matching technology, applied in accelerators, electrical components, etc., can solve the problems of inconvenient on-site installation and large volume of the spiral resonator, and achieve the effect of solving inconvenient installation and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

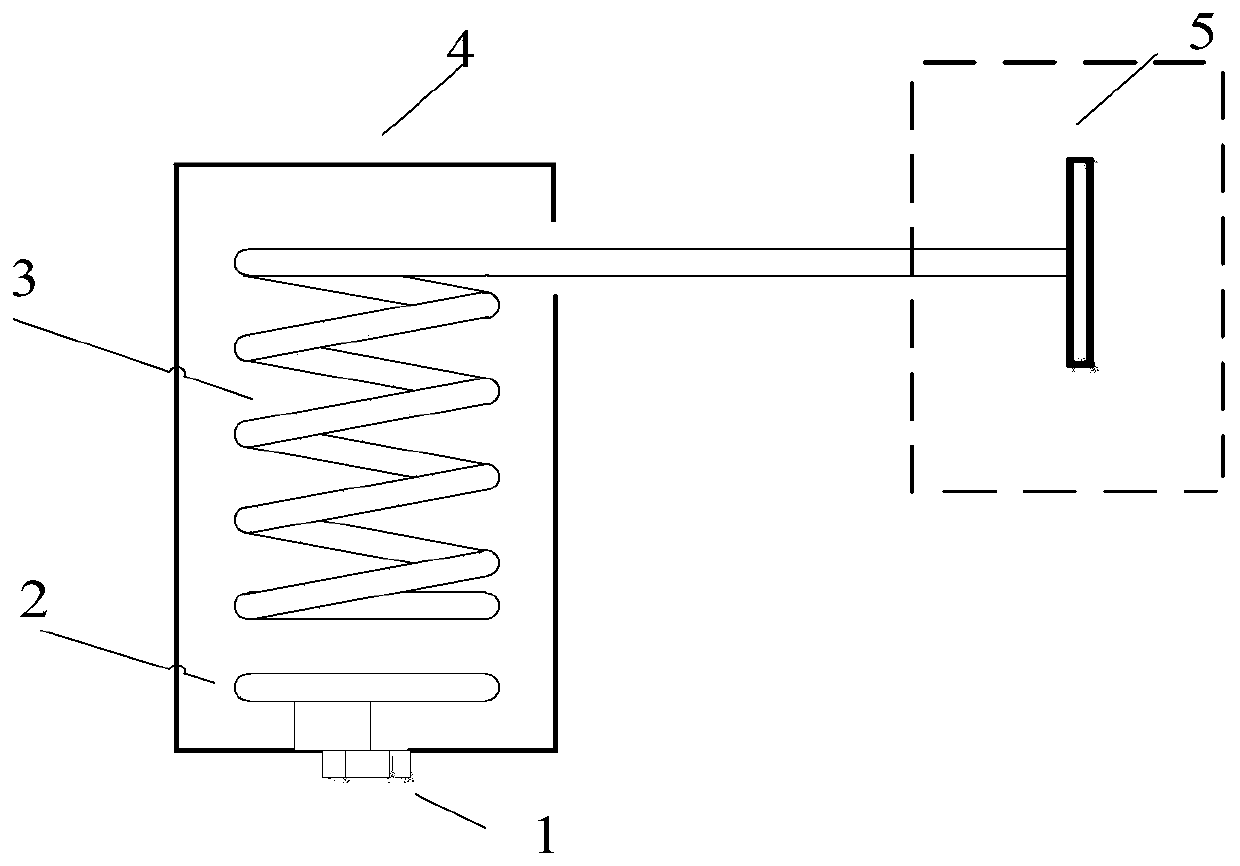

[0090] Such as figure 1 Shown is a schematic diagram of a high-frequency matching method for a MHz-level beam cutter provided by the present invention. The system is mainly composed of 1, 2, 3, 4, 5 and other components.

[0091] The power feed-in port 1 is used to feed the high-frequency signal provided by the power source into the spiral resonator through the coupling ring. The power feed-in port is placed on the bottom side of the square 4 of the shielded shell; Connect the power feed-in port to feed in power, and the other end is connected to one side of the square bottom side of the shielding shell; the center of the solenoid coil 3 starting end is 45-55 mm from the center of the coupling coil, and the starting end is connected to the shielding shell. The high-voltage side of the solenoid coil is connected to the cutting plate 5 through a coaxial feeder tube to provide a high-frequency voltage with a peak-to-peak value of 12KV and a frequency of 1-3MHz for the plate. Th...

Embodiment 2

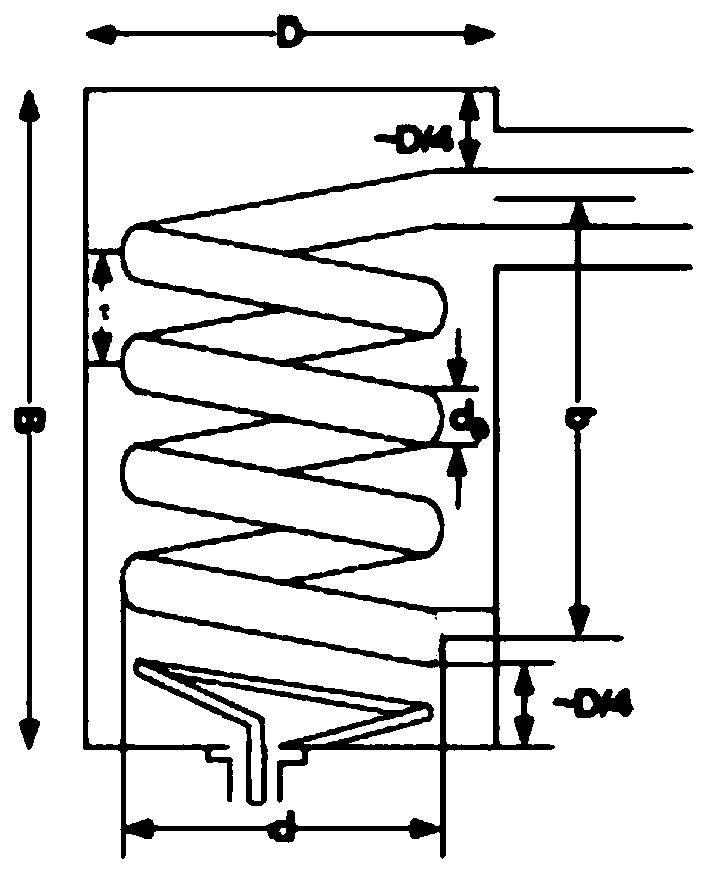

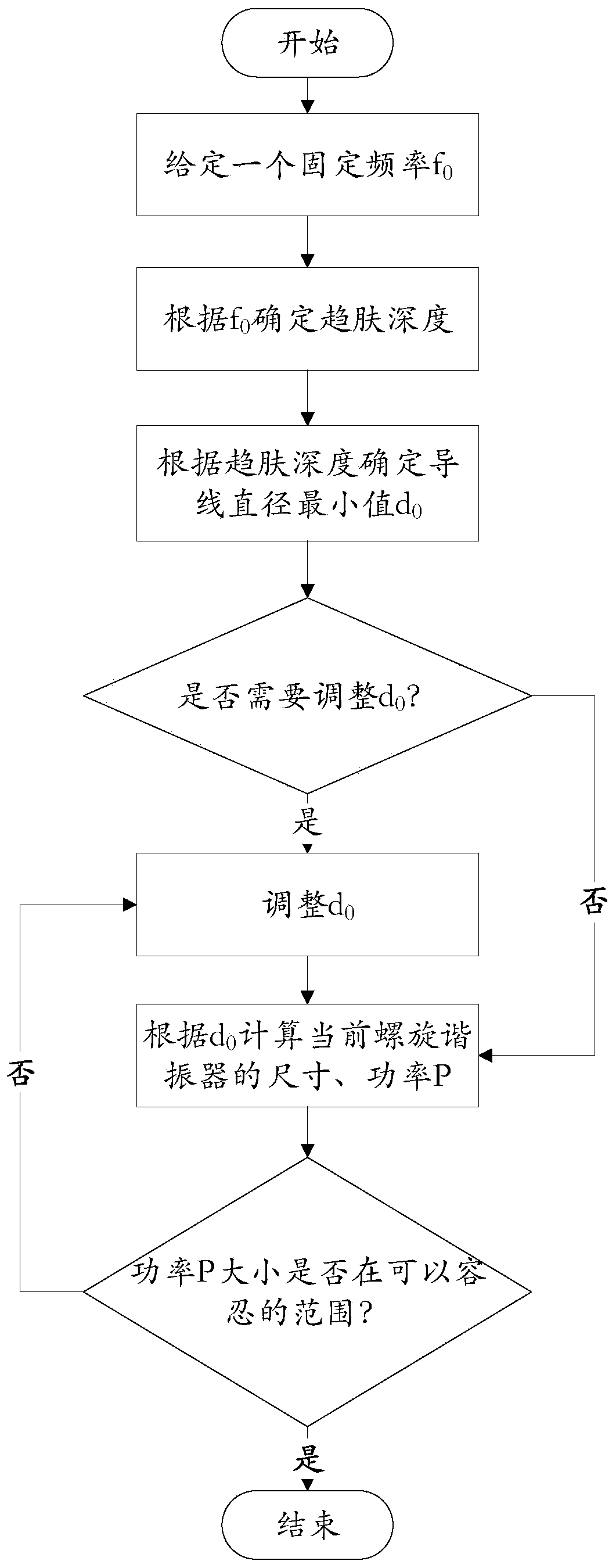

[0093] In this spiral resonator design scheme, first select copper wires (or copper tubes, but the wall thickness is greater than the skin depth) with a solenoid wire diameter of 3 to 12 mm, and then calculate the spiral resonance according to the size calculation formula at a fixed frequency The size of the resonator shell and the solenoid, and calculate the quality factor Q value, equivalent parallel resonance impedance, inductance value, etc., and finally calculate the theoretical power consumption and possible measured power consumption of the spiral resonator. According to experience, the actual power loss that may be measured Generally, it is about 2 times of the theoretical value. Since the theoretical power consumption is only an estimate, when there is a difference between the theoretical estimate and the actual measured power consumption, there is no need to adjust the power consumption, and the actual measured power consumption shall prevail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com