Water-fertilizer recycling system and method

A water and fertilizer, external circulation technology, applied in the fields of botanical equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problems of difficult source of high-quality soil, difficult construction, and high operating costs, and achieve continuous water and fertilizer efficiency benefits and improve utilization efficiency. , the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

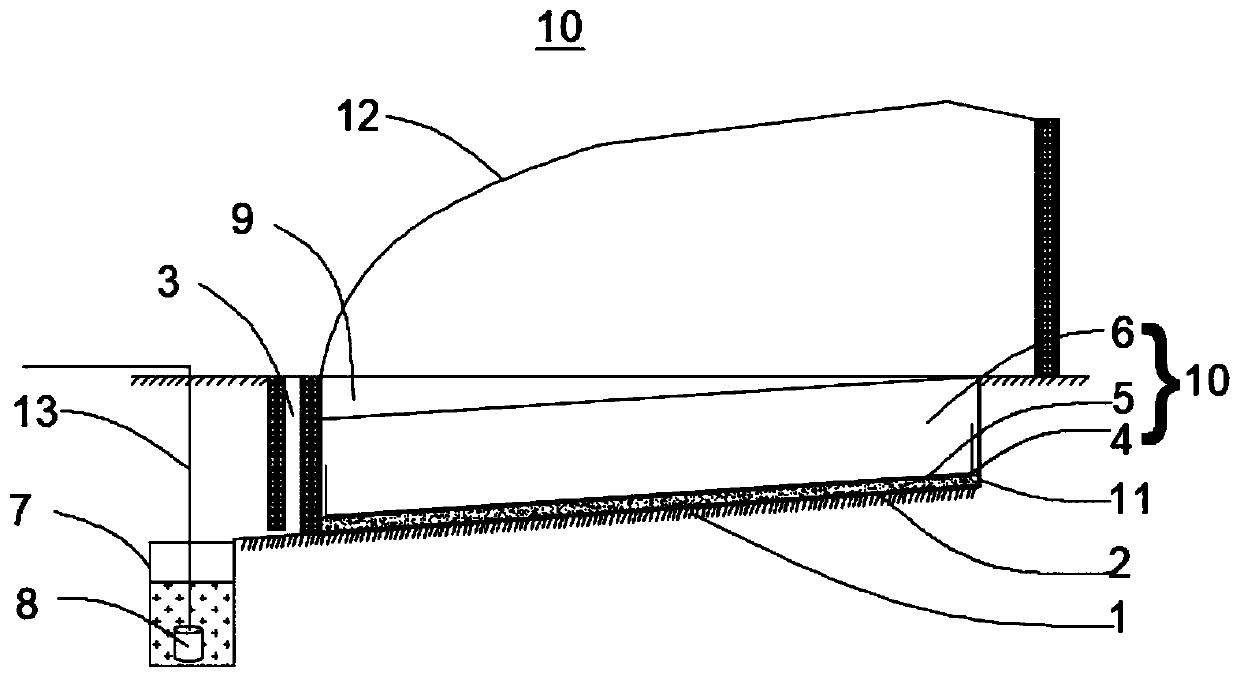

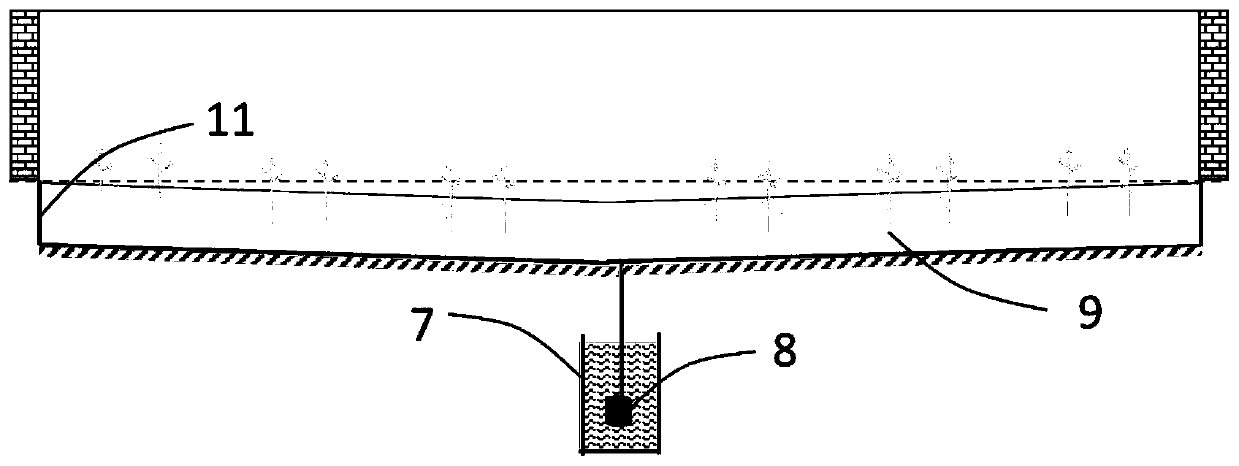

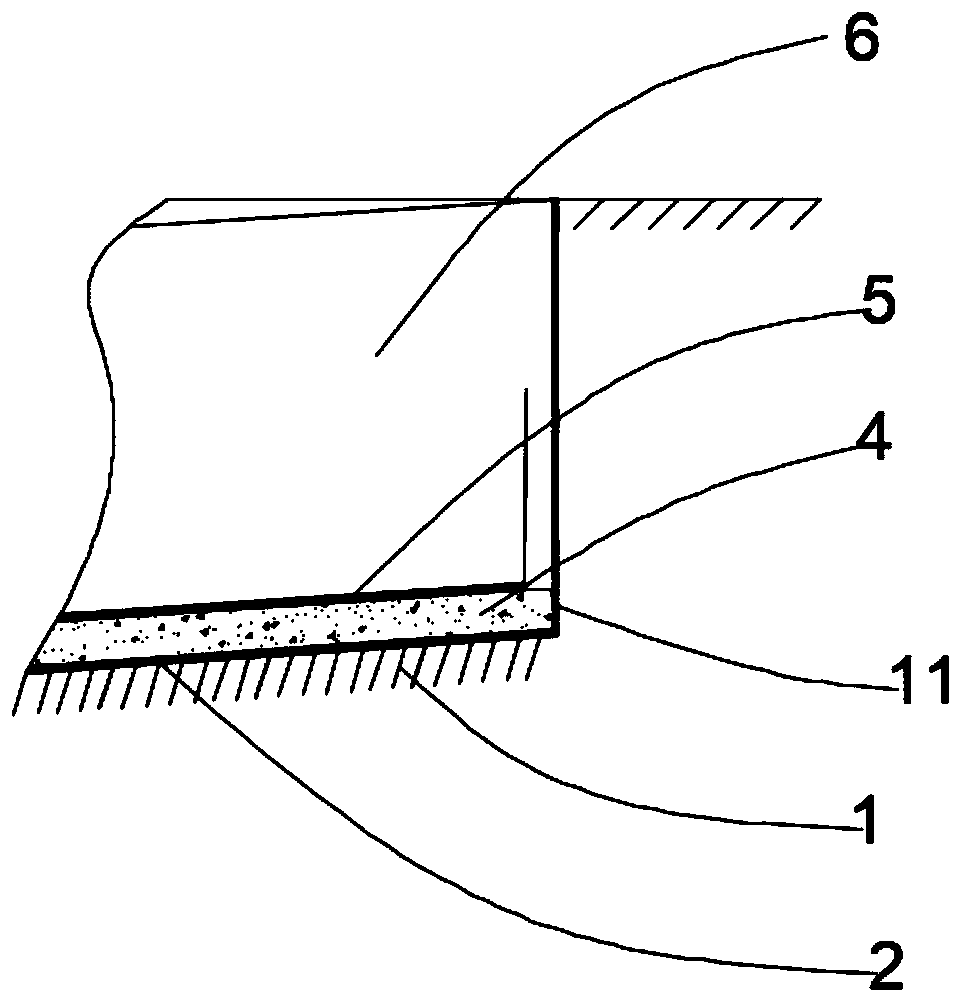

[0038] This embodiment provides a water and fertilizer recycling system, which can be combined with conventional greenhouse planting to recollect and utilize the water and fertilizer leaking along the planting soil layer to realize the recycling of water and fertilizer, thereby greatly improving the efficiency of water and fertilizer utilization in desert facility agriculture .

[0039] see in conjunction Figure 1 to Figure 3 The water and fertilizer recycling system 100 provided by the present invention includes a cultivation pit 9, a diversion tank 3 and a return pool 7. The diversion tank 3 is set on one side of the cultivation pit 9 and is infiltrated with the cultivation pit 9. The return pool 7 communicates with the diversion groove 3, and is used to collect the water and fertilizer flowing out of the diversion groove 3, cultivate the bottom surface of the foundation pit 9 to form the engineering base surface 1, and the first anti-seepage geotextile 2 is laid on the eng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com