Extrusion-ECAP extrusion deformation device and method for preparing fine-grained material

A technology of extrusion deformation and fine grain, which is applied in the field of material processing, can solve the problems of short material length and inability to be widely used in engineering fields, and achieve the effect of improving material strength, meeting requirements, and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

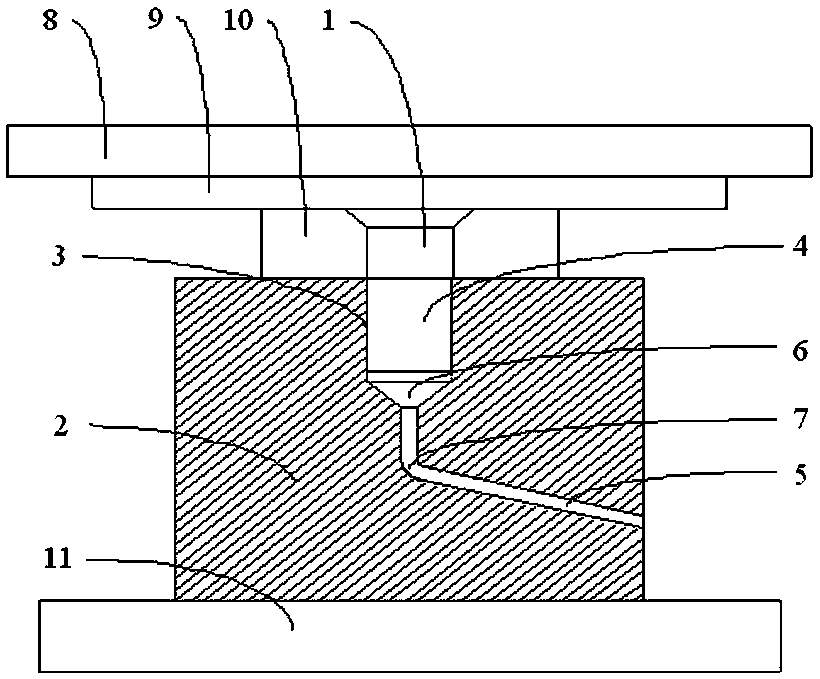

[0029] Such as figure 1 As shown, the device of the present invention comprises an upper mold 1 and a lower mold 2, and the lower mold 2 is provided with an extruding cylinder 3 for placing materials, and the bottom of the upper mold 1 is provided with an extrusion cylinder 3 top open end for inserting and displacing the material. The punch 4 that is extruded from the outlet end of the bottom of the extrusion cylinder 3; the lower die 2 also includes an equal-diameter extrusion channel 5 located in the lower mold 2; wherein, the bottom of the extrusion cylinder 3 has a diameter that gradually decreases Funnel-shaped 6, the outlet end of the bottom of the extruding cylinder 3 is docked with the inlet end of the extrusion channel 5, and the middle part of the extrusion channel 5 is a knuckle 7 that is set at an angle, and the outlet end of the extrusion channel forms an outlet on the outer wall of the lower die.

[0030] In this embodiment, more specifically, the lower mold 2 is...

Embodiment 2

[0036] (1) Melting in a vacuum induction melting furnace protected by argon, and then casting to obtain qualified magnesium alloy ingots;

[0037] (2) After heating the heat treatment furnace to about 400°C, put in the magnesium alloy ingot, keep it warm for 12 hours, and perform homogenization heat treatment to eliminate microsegregation;

[0038] (3) Cool the material to room temperature with the heat treatment furnace, and then machine it into an extrusion billet;

[0039] (4) Preheat the extrusion billet to 250°C, apply a lubricant on the surface of the billet and the inner surface of the extrusion cylinder, and then put the billet into the extrusion cylinder for extrusion, so that the extrusion deformation and ECAP deformation of the billet occur , to obtain a rod of Φ8mm×100cm, the extrusion temperature is 250°C, the extrusion rate is 4mm / s, and the extrusion ratio is 25;

[0040] (5) The extruded bar is subjected to solution annealing, the annealing process is 410°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com