Modified polytetrafluoroethylene and its preparation method and modified polytetrafluoroethylene parts

A polytetrafluoroethylene, modified technology, applied in the field of modified polytetrafluoroethylene materials, can solve the problem of graphene being difficult to disperse evenly, and achieve the effect of not easy to reunite, strong attraction, uniform and stable existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides a kind of preparation method of modified polytetrafluoroethylene, comprises the following steps:

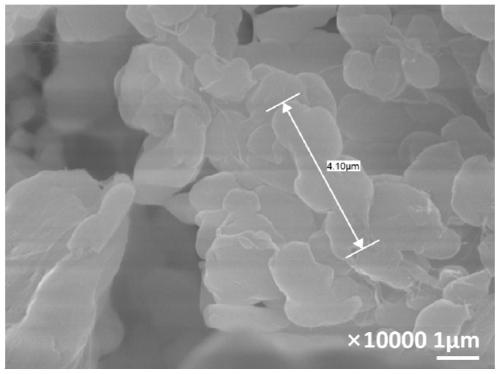

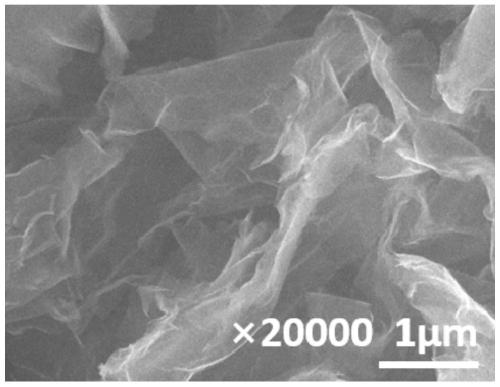

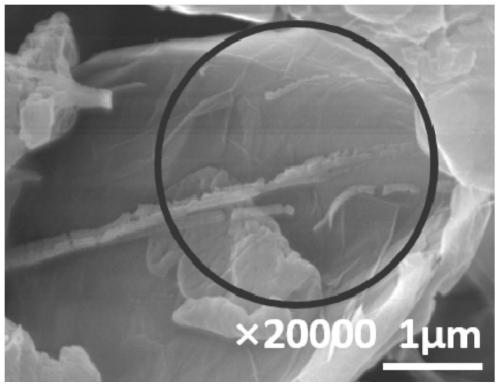

[0026] The modified polytetrafluoroethylene in which the surface of the polytetrafluoroethylene microsphere is chemically bonded to the graphene oxide sheet is obtained by carrying out amide reaction between polytetrafluoroethylene microspheres modified with amino groups on the surface and graphene oxide sheets modified by acid chloride.

[0027] In the modified polytetrafluoroethylene and its preparation method provided by the embodiments of the present invention, by modifying the amino group on the surface of polytetrafluoroethylene, modifying the acid chloride group on the graphene oxide sheet, using the amide reaction of the amino group and the acid chloride group to make the polytetrafluoroethylene Ethylene and graphene oxide sheets are combined by chemical bonds to obtain modified polytetrafluoroethylene. Through the a...

Embodiment 1

[0051] (1) Pretreatment of PTFE microspheres

[0052] Select PTFE micropowder as polytetrafluoroethylene microspheres, and place them in an environment of 23-25°C for 24-28 hours.

[0053] (2) Preparation of modified polytetrafluoroethylene

[0054] Place the pretreated 1g of polytetrafluoroethylene microspheres in 100ml of glucose solution with a concentration of 0.15mol / L and mechanically stir at a stirring speed of 150r / min. Transfer the uniformly stirred solution to a 200mL hydrothermal reaction kettle. Hydrothermal carbonization reaction at 160°C for 10 hours. The product after the hydrothermal reaction was rinsed with deionized water, placed in an oven, and dried at 80° C. for 12 hours to obtain hydroxylated polytetrafluoroethylene.

[0055] 10g 3-aminopropyltriethoxysilane is added in 120ml ethanol to obtain mass fraction and is the 3-aminopropyltriethoxysilane ethanol solution of 10wt%, then to 3-aminopropyltriethoxysilane ethanol solution Add 1g of hydroxylated pol...

Embodiment 2

[0063] The preparation method is basically the same as in Example 1, the difference is that the final product obtained in step (2) is not spray-dried, but the final product is placed in an oven and dried at 60°C to obtain modified polytetrafluoroethylene Vinyl powder. Then, the modified polytetrafluoroethylene part was prepared according to the preparation method of the modified polytetrafluoroethylene part in step (4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com