Fire prevention layer with composite structure and battery system using fire prevention layer

A battery system and composite structure technology, applied in the direction of structural parts, battery pack parts, and isolation of batteries from their environment, can solve problems such as damage, low strength, and lack of heat insulation, and achieve reasonable structural design, fire prevention, and ease of use. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

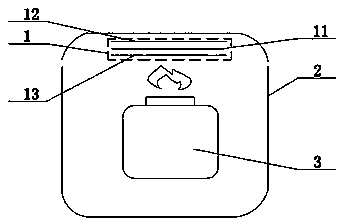

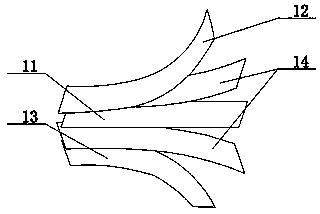

[0015] see Figure 1-Figure 2 As shown, the technical scheme adopted in this specific embodiment is: it comprises a fireproof layer 1, a skeleton layer 11, a thermal insulation layer 12, an impact-resistant layer 13, an adhesive 14, a battery system case cover 2, and a battery 3. The fireproof layer 1 The center is a skeleton layer 11, which has high temperature resistance, and the skeleton layer 11 is a wire mesh layer or a metal sheet layer, a heat insulation layer 12 is arranged above the skeleton layer 11, and an impact-resistant layer 13 is arranged below the skeleton layer 11 , the impact-resistant layer 13 is a high-temperature-resistant flexible material layer, the heat-insulating layer 12 is bonded and fixed on the upper surface of the skeleton layer 11 through the adhesive 14, the impact-resistant layer 13 is fixed on the lower surface of the skeleton layer 11 through the adhesive 14, and the surface of the battery 3 is covered with fireproof Layer 1, the battery 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com