Metal packaged liquid coffee beverage and production method thereof

A technology of coffee drinks and liquids, applied in coffee, coffee extraction, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this example, a liquid coffee beverage was prepared as follows.

[0066] 1. Raw materials

[0067] Table 1 Example 1 formula table

[0068]

[0069]

[0070] 2. Preparation method

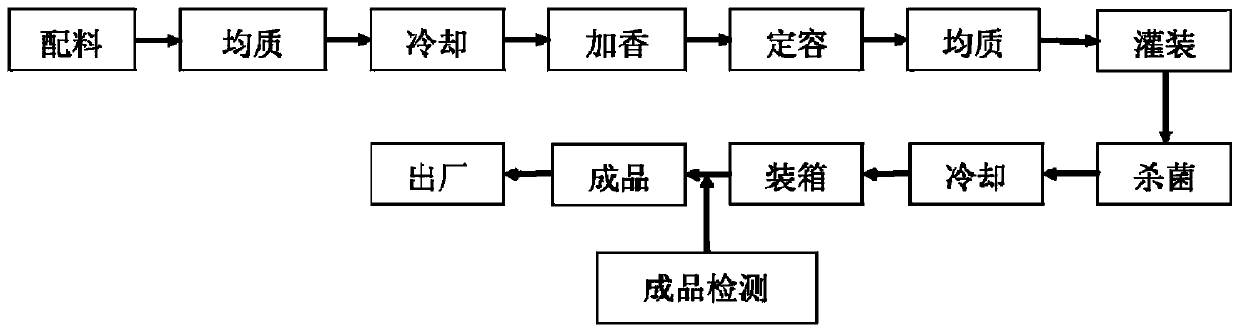

[0071] See the process flow figure 1 .

[0072] (1) Ingredients:

[0073] Step 1: Add water (45°C-55°C) to the high-speed blender and turn on the blender, add 1 / 2 the recipe amount of casein, 1 / 2 sodium caseinate, 1 / 2 resistant dextrin, 7 / 20 recipe A certain amount of erythritol, after stirring for 10 minutes, is filtered through an 80-mesh filter and pumped into the rehydration tank.

[0074] Step 2: Repeat step 1, and let the feed liquid in the rehydration tank stand for 25-30 minutes.

[0075] Step 3: Divide the remaining 3 / 10 erythritol into 2 parts, the emulsion stabilizer of the pre-mixed formula (including mono-, diglyceride fatty acid ester, sucrose fatty acid ester, diacetyl tartaric acid mono-diglyceride, Microcrystalline cellulose, disodium hydrogen phosphate, sodi...

Embodiment 2

[0108] The liquid coffee drinks prepared in Example 1 and Comparative Examples 1-6 were analyzed for their state, stability and satiety after sterilization, and the results are shown in Table 2.

[0109] The prepared liquid coffee beverage of embodiment 1 sees figure 2 , good flavor and taste, high stability, not prone to fat floating phenomenon, and has the effect of enhancing satiety.

[0110] In Comparative Example 1, because whey protein was added, the protein was denatured under high temperature and high pressure sterilization conditions at 121° C. for 20 minutes, resulting in a jelly-like product.

[0111] In comparative example 2, because the added amount of casein is reduced, the satiety time of the product is reduced.

[0112] In Comparative Example 3, because no carrageenan was added, the fat floating phenomenon and the precipitation of tiny particles would occur relatively quickly during the shelf life of the product. Carrageenan is a thickener. When added in an ...

Embodiment 3

[0117] Prepare liquid coffee beverage according to the method for embodiment 1, difference is that formula table is as follows:

[0118] The formula table of table 3 embodiment 3

[0119] ingredients Formula amount (%) casein 5.5 sodium caseinate 0.1 Anhydrous Cream 1.0 coconut oil 5.0 medium chain triglycerides 1.8 resistant dextrin 1.8 Erythritol 3.0 coffee extract 8.5 trisodium phosphate 0.10 Mono, Diglycerides of Fatty Acids 0.12 Sucrose Fatty Acid Ester 0.25 Diacetyl tartrate mono-diglycerides 0.02 microcrystalline cellulose 0.15 Disodium phosphate 0.03 Hexametaphosphate 0.03 Sodium carboxymethyl cellulose 0.15 carrageenan 0.05 food flavor 0.06 water make up

[0120] The coffee beverage obtained in this embodiment has the property of enhancing satiety, good taste, strong stability, and stronger satiety than other formulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com