Dipped film adhesive veneer core board applied by cross-band veneer and manufacturing method thereof

A technology for impregnating adhesive film paper and blockboard, applied in the field of boards, can solve the problem of reducing the aesthetics and performance of the impregnated adhesive film paper facing blockboard, and affecting the transverse static bending strength surface of the impregnated adhesive film paper facing blockboard. Flatness and other issues, to achieve the effect of good lateral static bending strength, strong bearing capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 A blockboard with impregnated adhesive film paper facing for core board application

[0040] In this embodiment, by changing the placement direction of the veneer 1 in the core board 3 of the impregnated film paper veneer blockboard, the deformation direction of the core board 3 is staggered with the wood grain direction of the veneer 1, so that the direction of the veneer 1 in the core board 3 The internal stress of the core board 3 changes, thereby improving the anti-deformation ability and surface smoothness of the impregnated film paper facing blockboard applied to the core board 3 .

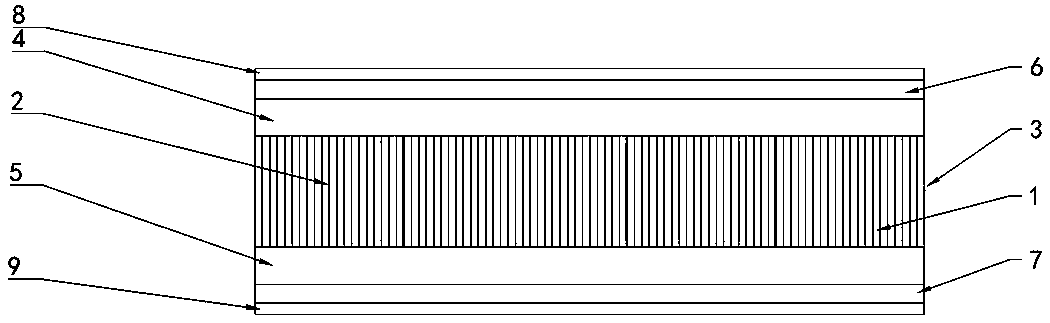

[0041] Such as figure 1 As shown, this embodiment includes an upper surface layer 8 , an upper decorative layer 6 , an upper veneer layer 4 , a core board 3 , a lower veneer layer 5 , a lower decorative layer 7 and a lower surface layer 9 that are mutually bonded from top to bottom.

[0042] (1) Core board 3

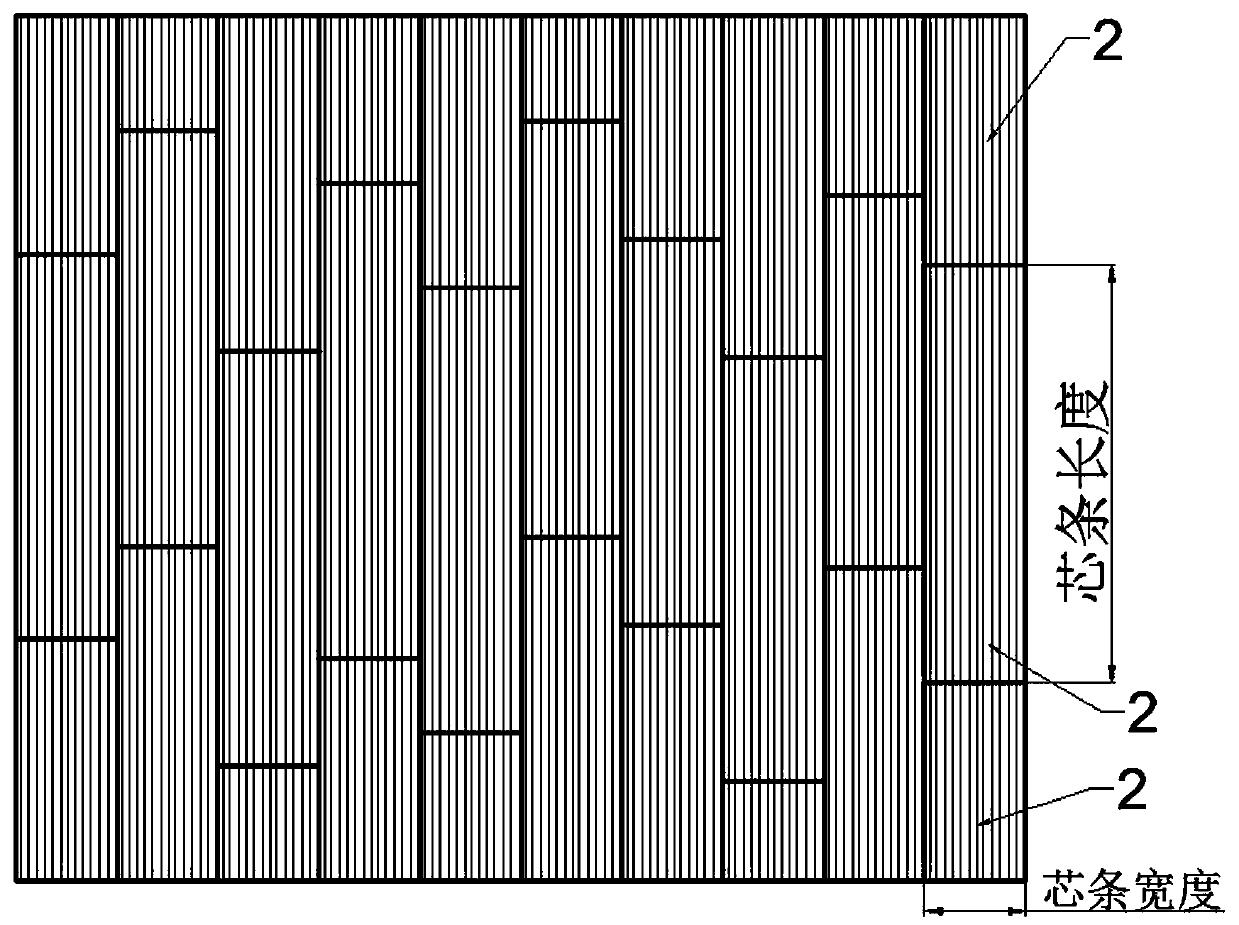

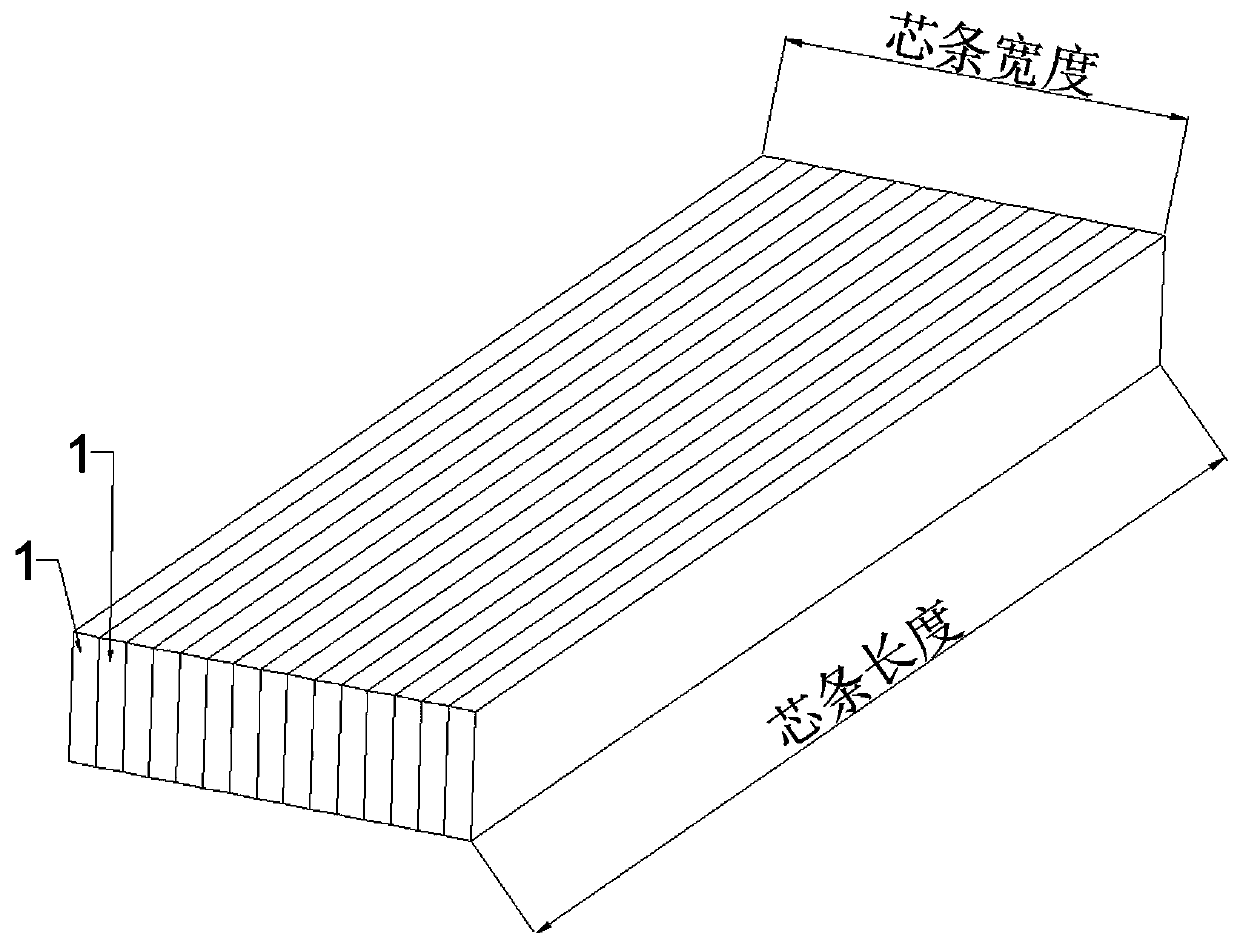

[0043] Such as Figure 2 to Figure 3 As shown, the core board ...

Embodiment 2

[0055] Example 2 A method of making blockboard with impregnated adhesive film paper facing for core board application

[0056] This embodiment is used to make the impregnated film paper veneer blockboard in embodiment 1, comprises the following steps:

[0057] (1) Hot pressing of veneer 1 set of blanks to form core strip 2

[0058] Adhesively glue the veneer 1 to the veneer 1, stack N layers in order from top to bottom, and complete the assembly of the veneer 1. Wherein, N≥2, in this embodiment, N=14.

[0059] After forming the billets, the veneer layer is hot-pressed by a hot-pressing machine. The hot-pressing unit pressure is 8-12 kg / cm2, the hot-pressing time is 15-30 minutes, and the hot-pressing temperature is 115-120°C to obtain the specified size. core strip 2.

[0060] It must be ensured that the stacking direction of the N-layer veneer 1 is located in the width direction of the core strip 2, and that the direction along the grain of the veneer 1 is located in the l...

Embodiment 3

[0065] Example 3 A method of making blockboard with impregnated film paper facing for core board application

[0066] This embodiment is used to make the impregnated film paper veneer blockboard in embodiment 1, comprises the following steps:

[0067] (1) Cut wood sections into veneers 1

[0068] The wood section is cut into veneers 1 by rotary cutting or slicing, and the cutting direction is perpendicular to the direction along the grain of the veneer 1 , and the direction along the grain of the obtained veneer 1 is consistent with the length direction of the veneer 1 . The wood section is any one of poplar, camphor and Chinese fir. The obtained veneer 1 has a length of 1265 mm, a width of 650 mm, and a thickness of 3 mm. After drying, the moisture content of the veneer 1 is less than 8%.

[0069] (2) Form the board square by hot pressing the 1 group blank of the veneer

[0070] Adhesively glue the veneer 1 to the veneer 1, stack N layers in order from top to bottom, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com