A kind of anti-shock seat device of ship

An impact-resistant and seat technology, applied in the field of mechanical vibration reduction, can solve the problems of small impact energy, unadjustable, high cost, etc., and achieve the effects of improving damping torque, overall force balance, and strong structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

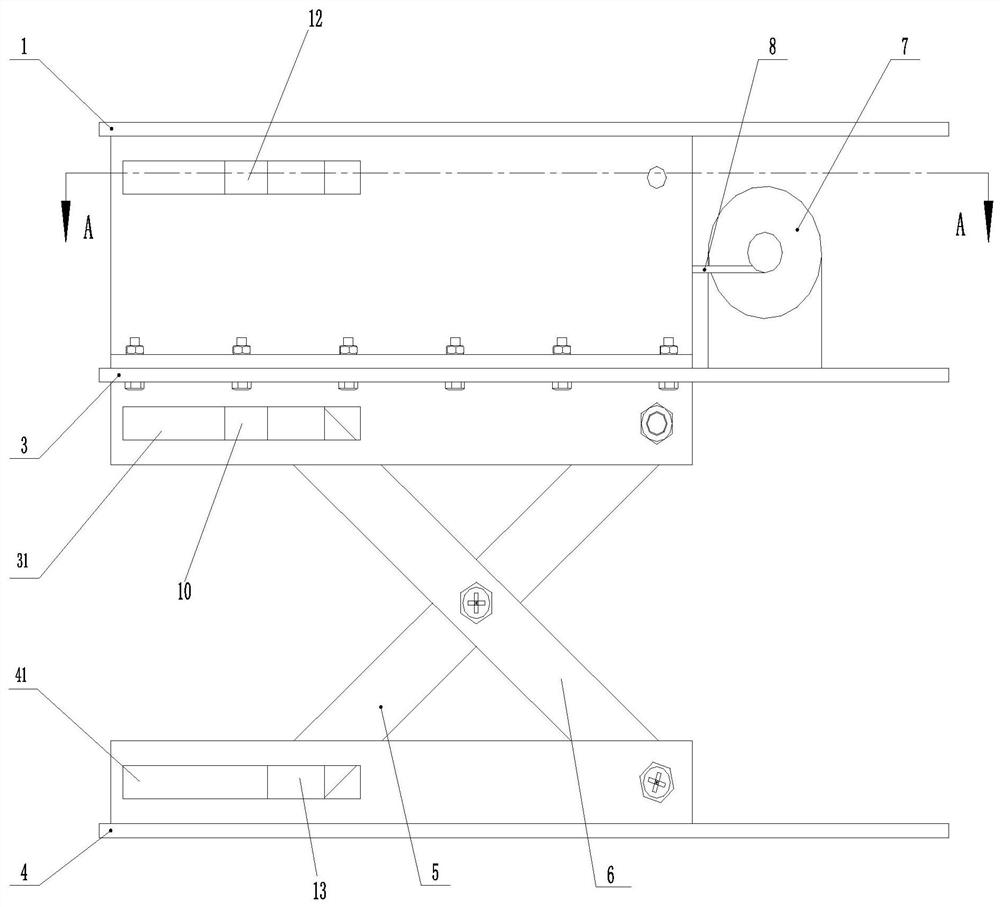

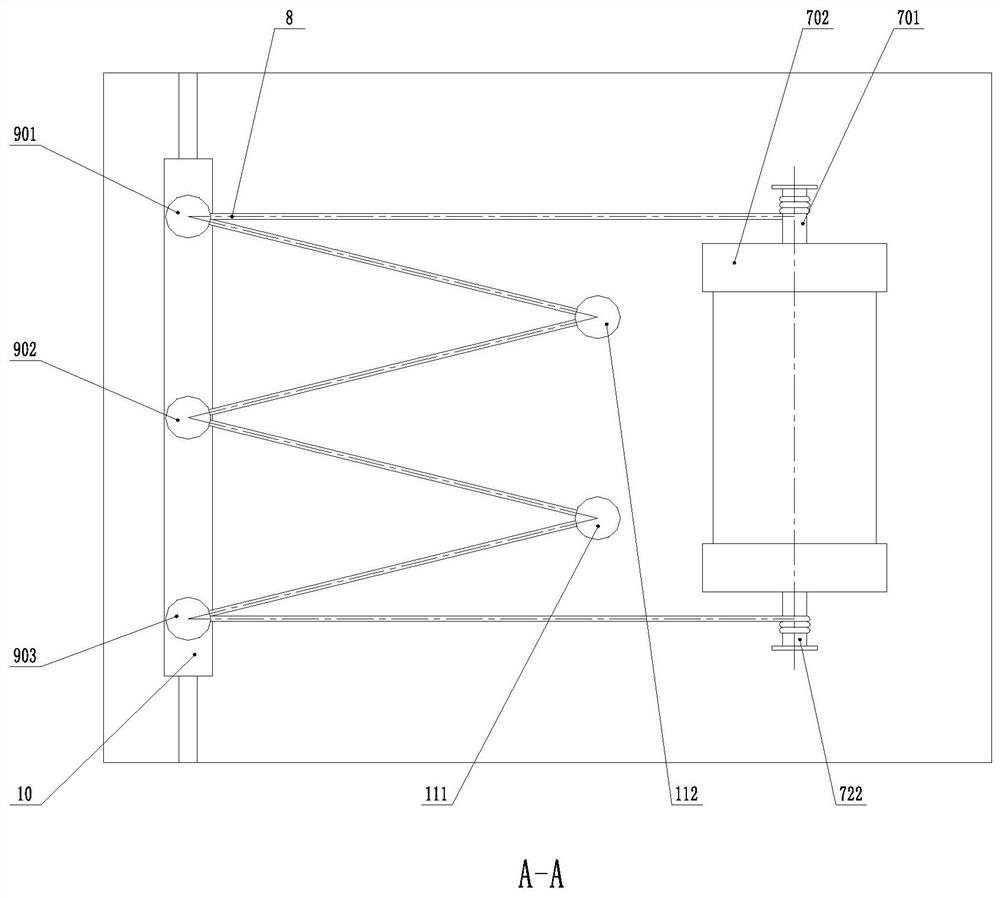

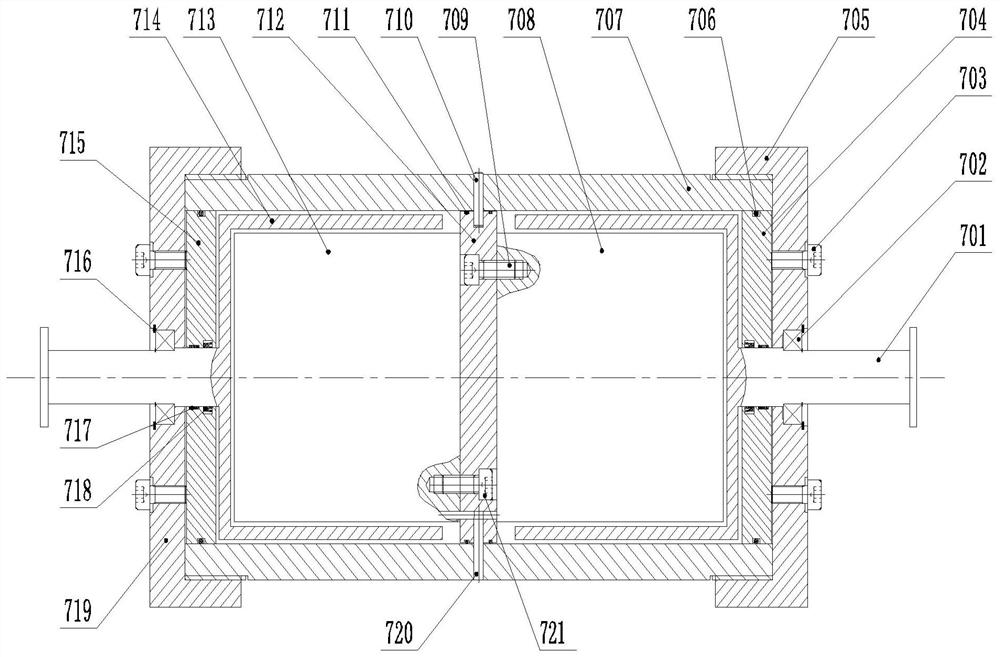

[0029] figure 1 It is a schematic diagram of the first structure of the present invention; figure 2 It is a schematic diagram of the structure of A-A of the present invention; image 3 It is a structural schematic diagram of the damper of the present invention; Figure 4 It is a schematic diagram of coil layout of the radial magnetic field of the damper core of the present invention; Figure 5It is an axonometric schematic diagram of the present invention; as shown in the figure; a new type of anti-shock seat device for ships, including a seat upper board 1, a seat middle board 3 and a seat lower board 4 arranged sequentially from top to bottom; The seat upper board 1, the seat middle board 3 and the seat lower board 4 are respectively provided with a first slide bar 12, a second slide bar 10 and a third slide bar 13 which can slide along the horizontal direction of the seat, so that Between the first slide bar 12 and the second slide bar 10, a plurality of first pulleys a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com