Cesium lead halide perovskite thick film as well as preparation and application thereof

A cesium lead halide and perovskite technology, applied in the field of radiation detection, can solve the problems of inconsistent orientation, complex process, low sensitivity, etc., and achieve the effect of avoiding air holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

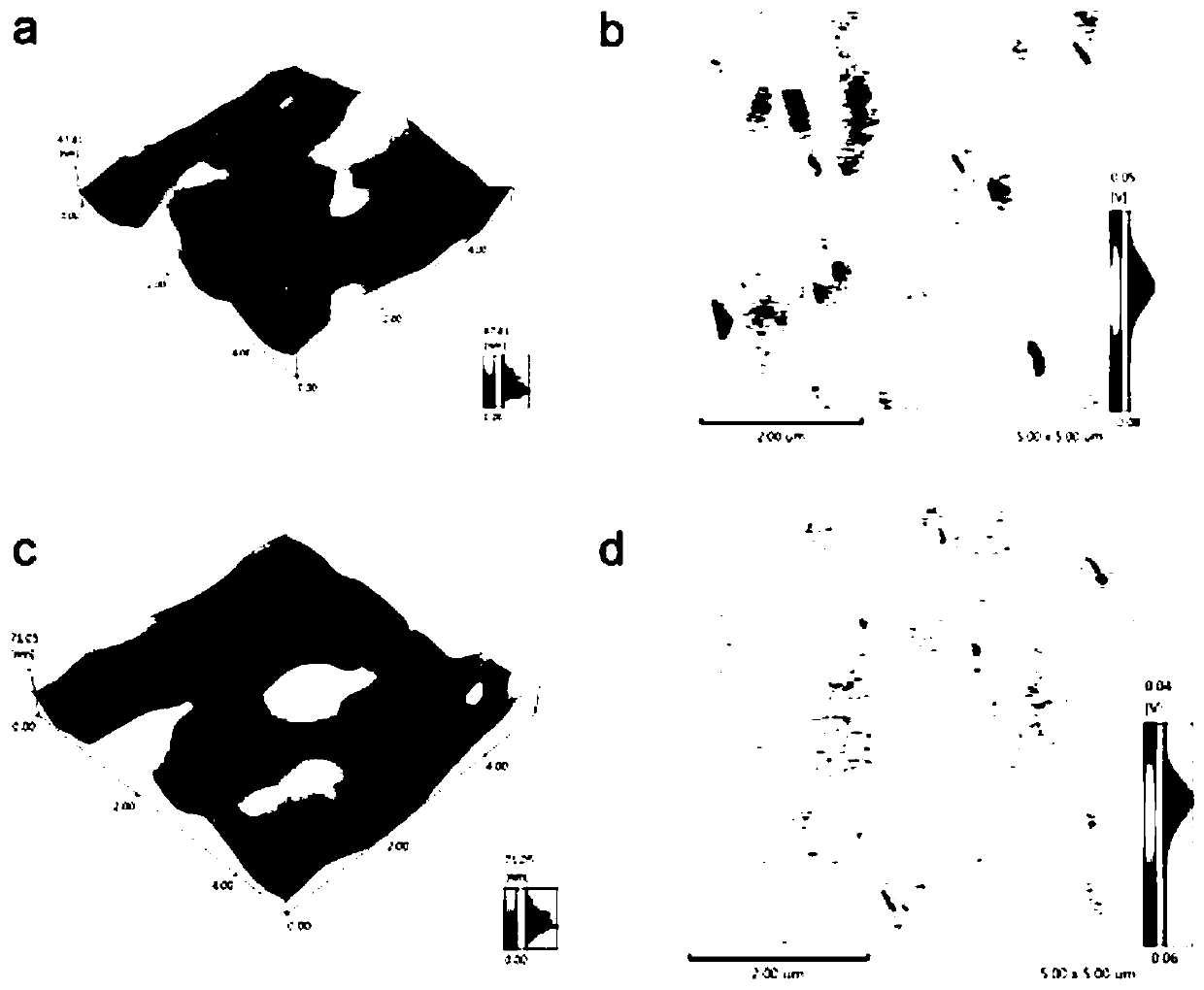

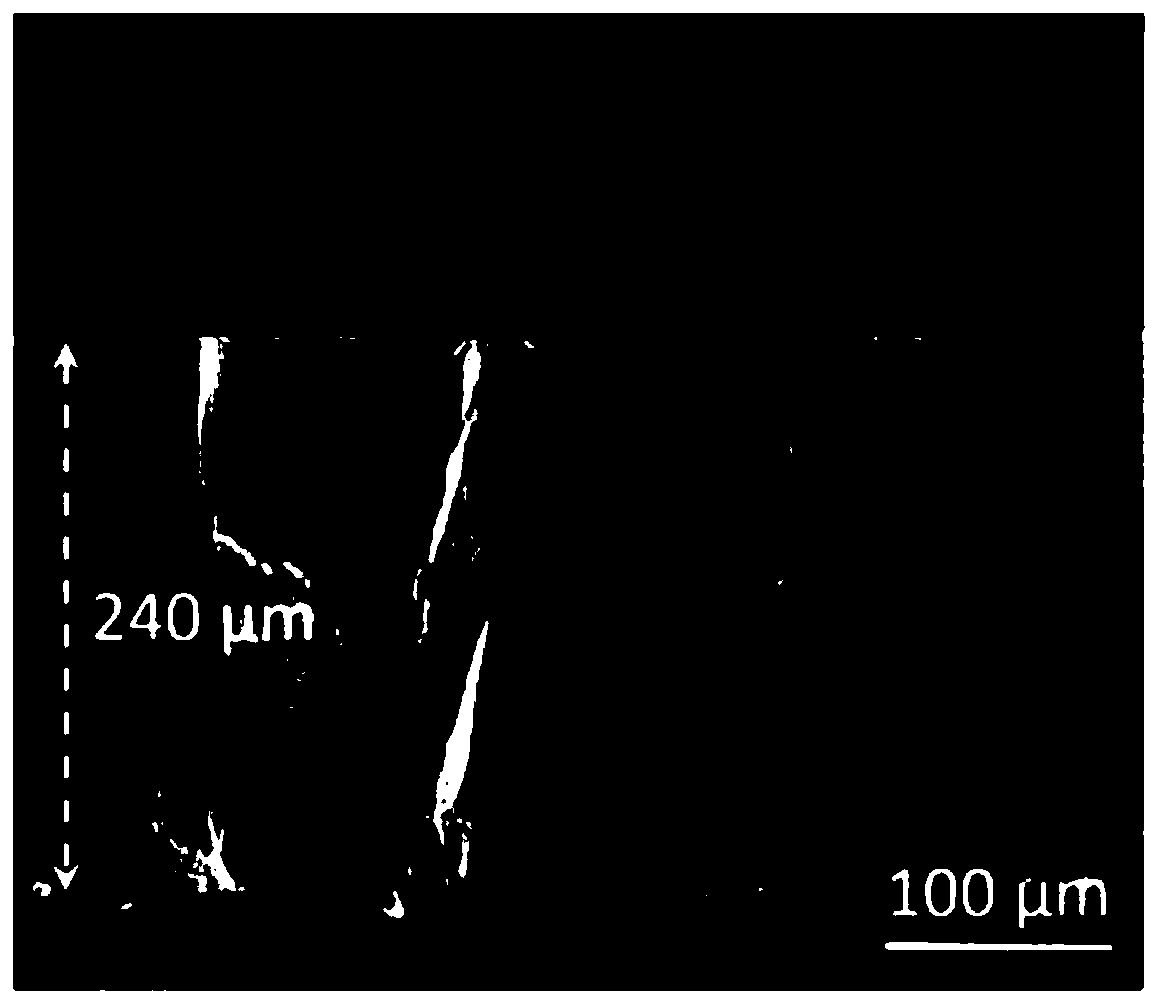

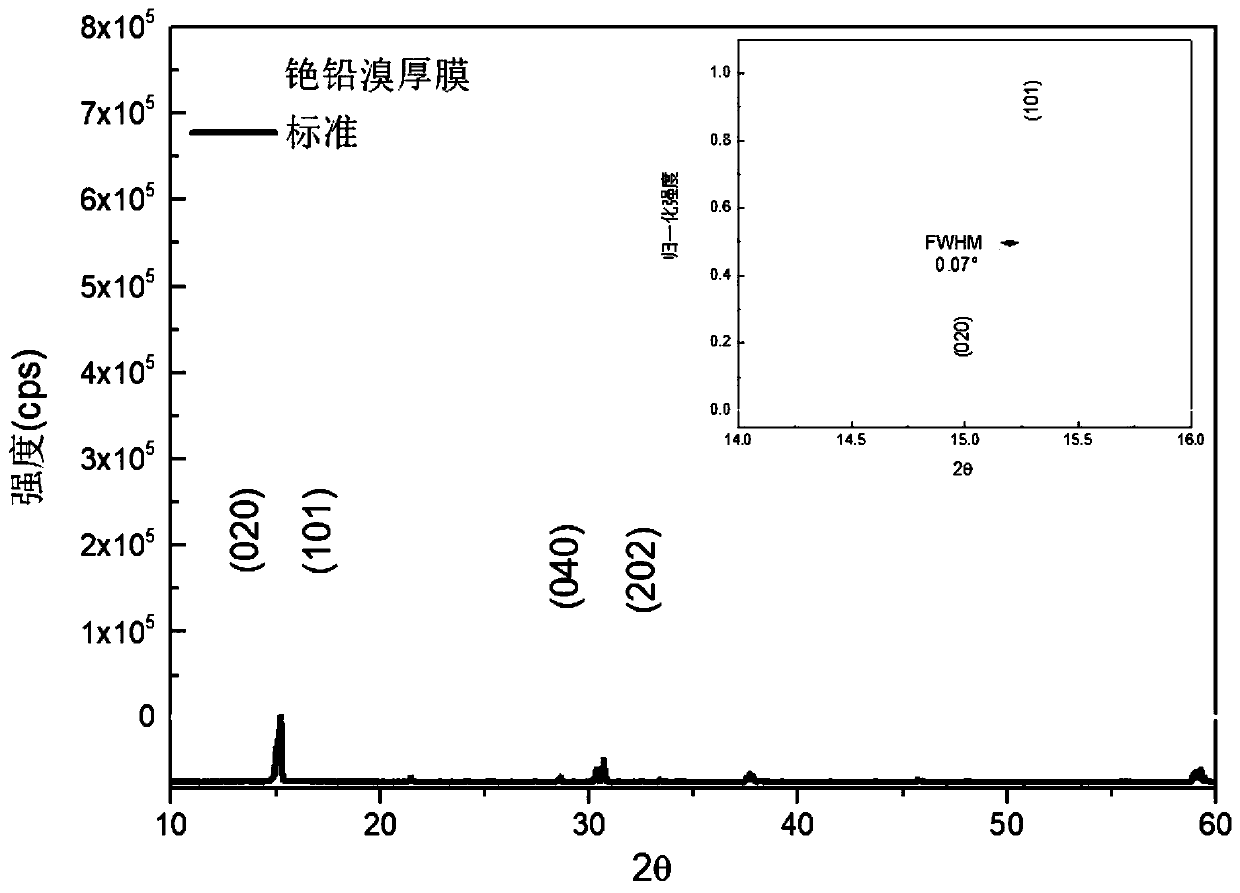

[0033] This example will introduce the preparation of 240um cesium lead bromide perovskite thick film on FTO substrate:

[0034] Take (0.5g) cesium lead bromide (CsPbBr 3 ) powder, spread the powder evenly on the FTO of 2.5cm×2.5cm, heat the FTO and powder to 600°C for 5min, cesium lead bromide (CsPbBr 3 ) powder melted into a liquid state, the quartz sheet heated in the same furnace was covered on the liquid cesium lead bromine, and then cooled to room temperature at a speed of 5°C / min, and then the quartz sheet was uncovered to obtain a cesium lead bromine thick film on the FTO substrate.

Embodiment example 2

[0036] This example will introduce the preparation of 480um cesium lead bromide perovskite thick film on FTO substrate:

[0037] Take (1g) cesium lead bromide (CsPbBr 3 ) powder, spread the powder evenly on the FTO of 2.5cm×2.5cm, heat the FTO and powder to 600°C for 5min, cesium lead bromide (CsPbBr 3 ) powder melted into a liquid state, the quartz was covered on the liquid cesium lead bromine, and then cooled to room temperature at a rate of 5°C / min, and then the quartz sheet was uncovered to obtain a cesium lead bromine thick film on the FTO substrate.

Embodiment example 3

[0039] This example will introduce the preparation of 240um cesium lead iodine perovskite thick film on FTO substrate:

[0040] Take (0.6g) cesium lead iodide (CsPbI 3 ) powder, spread the powder evenly on the FTO of 2.5cm×2.5cm, heat the FTO and powder to 570°C for 5min, cesium lead iodide (CsPbI 3) powder melted into a liquid state, the quartz was covered on the liquid cesium lead iodine, and then cooled to room temperature at a rate of 5°C / min, and then the quartz sheet was uncovered to obtain a cesium lead iodine thick film on the FTO substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com