A high-temperature-resistant electric control device for high-temperature areas such as the top of a coke oven

An electric control equipment and high temperature resistant technology, applied in coking ovens, electrical program control, furnace safety devices, etc., can solve problems affecting the safe and reliable operation of electric control equipment, restricting the process of coking production automation, etc., to achieve reliable operation, Extensive selection and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further explanation will be further described below with reference to the embodiments of the present invention.

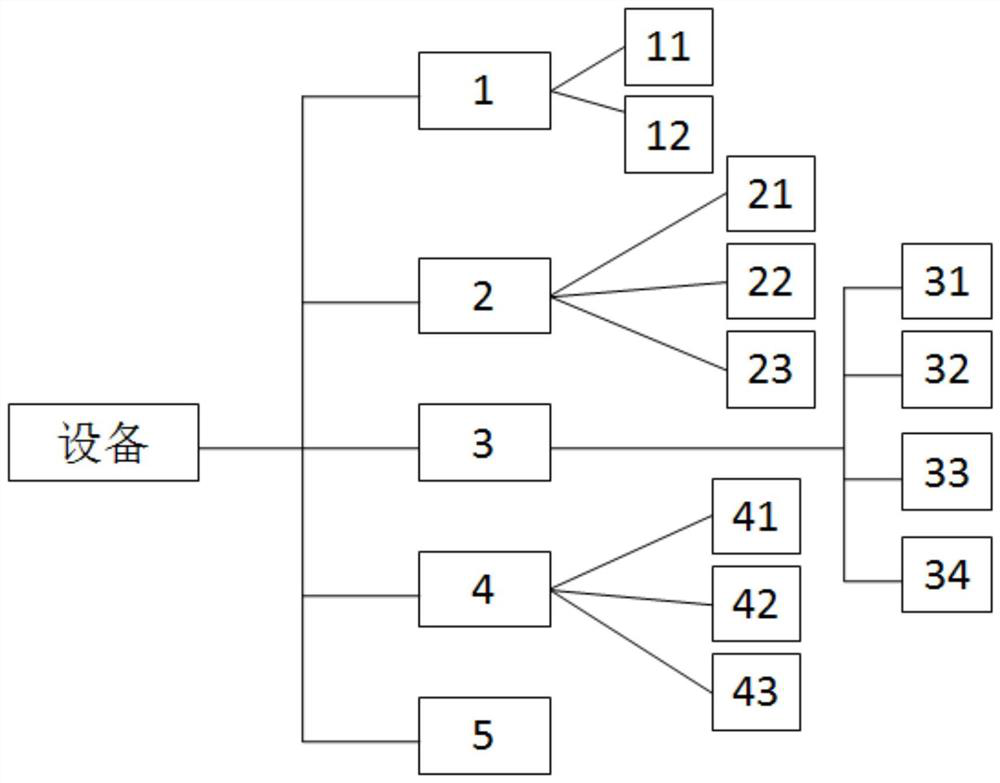

[0016] High temperature resistant electronic control equipment such as high temperature resistance of coke oven, including high temperature-resistant sealed cable bridge 1, high temperature sealed electrical plate 2, regional environment detection 3, refrigeration air supply system 4, emergency technology system 5 Here, high temperature sealed electrical plate 2 and the high temperature-resistant sealed cable bridge 1 is a sub-mother buckle combination, realizing insulation and sealing; at the same time, regional environment detection 3, refrigeration air supply system 4 and emergency technology system 5 Electrical connection.

[0017] The high temperature-resistant sealed cable bridge 1 includes an internal cable 11, wherein the outer casing 12 is a three-clad structure, which is fixedly coupled by a plurality of groups, wherein each interval and a groove. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com