Degumming composition and preparation method and application thereof

A composition and unsaturated technology, applied in the direction of detergent composition, non-surface active detergent composition, organic non-surface active cleaning composition, etc., can solve the problem of incomplete cleaning of portable cleaning machines, dermatitis and eczema, unsuitable Problems such as popularization and use, to achieve excellent glue removal efficiency, soft and fragrant taste, mild and non-pungent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

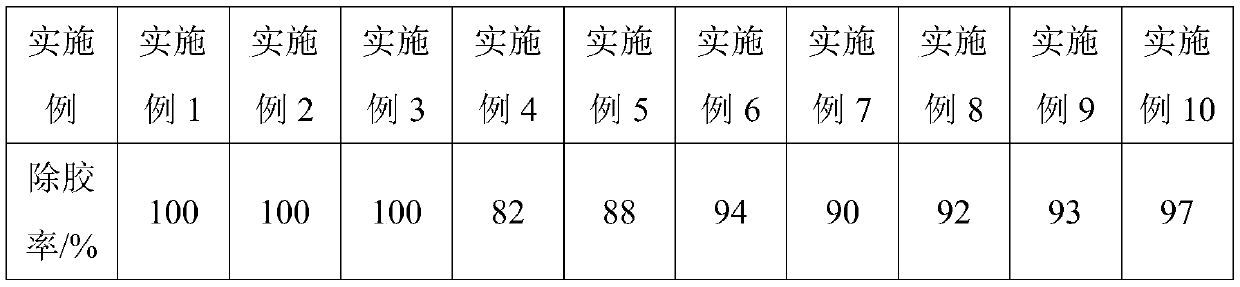

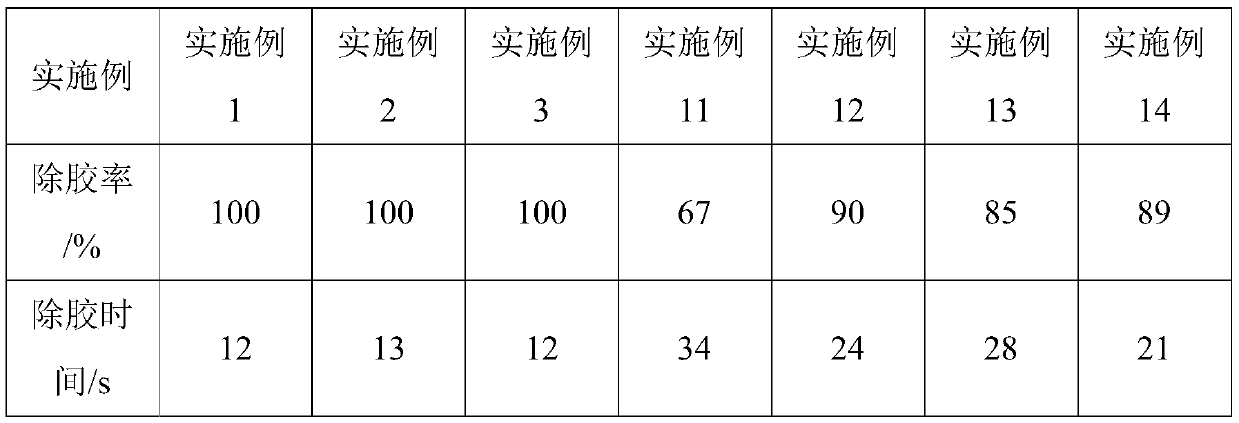

Examples

preparation example Construction

[0057] The second aspect of the present invention provides a preparation method of the degumming composition, which includes the following steps: firstly add limonene and co-solvent into a stirred tank for stirring; then add the remaining raw materials, continue stirring until dissolved, and let stand still Defoaming for 8-12 hours; finally filtered and packaged, ready to go.

[0058] The third aspect of the present invention provides the application of the gel removing composition, which can be applied to aerosols and gel removing liquids.

[0059] When the degumming composition is applied to an aerosol, the raw materials at least include 85-100 parts by weight of the degumming composition, 0.1-0.3 parts of preservatives, and 0.1-0.3 parts of rust inhibitors.

[0060] The aerosol also includes a propellant gas; the amount of the propellant gas is 0.1-0.5 wt% of the degumming composition.

[0061] The water content in the aerosol is less than 800 ppm.

[0062] When the aerosol is at 50...

Embodiment 1

[0067] Example 1 provides a degumming composition, in parts by weight, comprising the following raw materials: 60 parts of D-limonene, 72 parts of unsaturated acid esters, 45 parts of dehydrated solvent oil, 10 parts of dibasic acid esters, 15 parts of co-solvent, 8.6 parts of polyether derivative with amino group;

[0068] The unsaturated acid ester is methyl oleate;

[0069] The de-hydrocarbon solvent oil is selected from Shanghai Huishuo Chemical Co., Ltd. D110 environmentally friendly solvent oil;

[0070] The dibasic acid methyl ester monomers include 3.3 parts of dimethyl succinate, 5 parts of dimethyl glutarate, and 1.7 parts of dimethyl adipate;

[0071] The co-solvent is diethylene glycol butyl ether; CAS is 112-34-5;

[0072] The polyether derivative with amino group is 4-aminobutyraldehyde diethanol.

[0073] The preparation method of the degumming composition includes the following steps: first add limonene and co-solvent into a stirred tank for stirring; then add the remain...

Embodiment 2

[0075] The difference between Example 2 and Example 1 is that, in parts by weight, it includes the following raw materials: 50 parts of D-limonene, 50 parts of unsaturated acid esters, 35 parts of dehydrated solvent oil, 5 parts of dibasic acid esters, and auxiliary 10 parts of solvent, 2.5 parts of polyether derivative with amino group;

[0076] The dibasic acid ester includes 1.7 parts of dimethyl succinate, 2.5 parts of dimethyl glutarate, and 0.8 parts of dimethyl adipate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com