Method using laccase catalysis to prepare polyaniline

A technology for catalytic preparation and polyaniline, which is applied in the field of enzyme catalysis and can solve problems such as undisclosed sources of laccase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

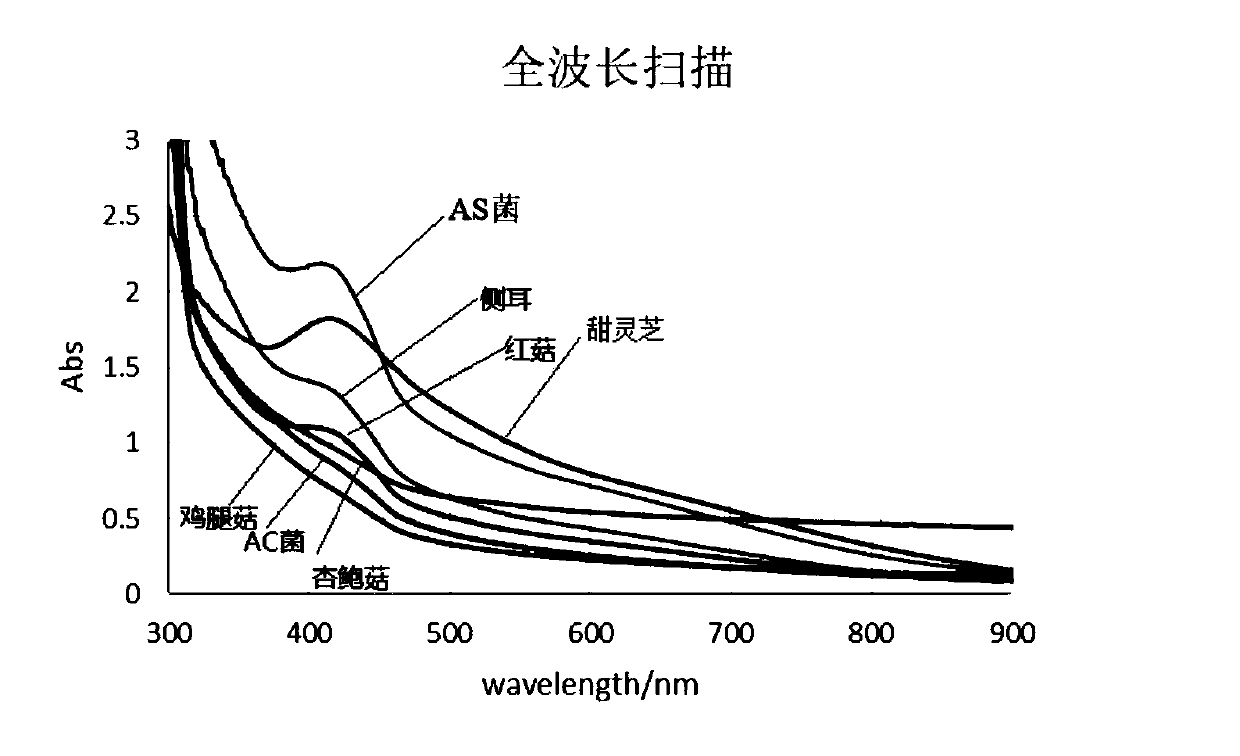

[0015] Laccases from different fungal species were used to catalyze the polymerization of aniline, and a 5ml centrifuge tube was used as a reactor, such as figure 1 as shown,

[0016] Add aniline, sodium dodecylbenzenesulfonate, and 0.4ml of crude laccase solution from different sources to the centrifuge tube, make up to 4ml with purified water, and then adjust the pH of the system to 3.0 by adding acetic acid buffer to form a reaction system, and let it stand at room temperature After 24 hours of reaction, it is obtained; the concentration of aniline in the reaction system is 10mmol / L, and the concentration of sodium dodecylbenzenesulfonate (SDBS) is 20mmo / L.

[0017] figure 1 From left to right in the middle are the crude enzyme solutions derived from Pleurotus eryngii, Coprinus comatus, AS bacteria, AC bacteria, Russula, Ganoderma lucidum, and Pleurotus. The results show that Ganoderma lucidum turns dark green after the reaction, and the color is the darkest, proving that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com