Printed circuit board air-cooled heat exchanger core

A technology for air-cooled heat exchangers and printed circuit boards, which is used in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc. The effect of short cycle time, large flow area and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

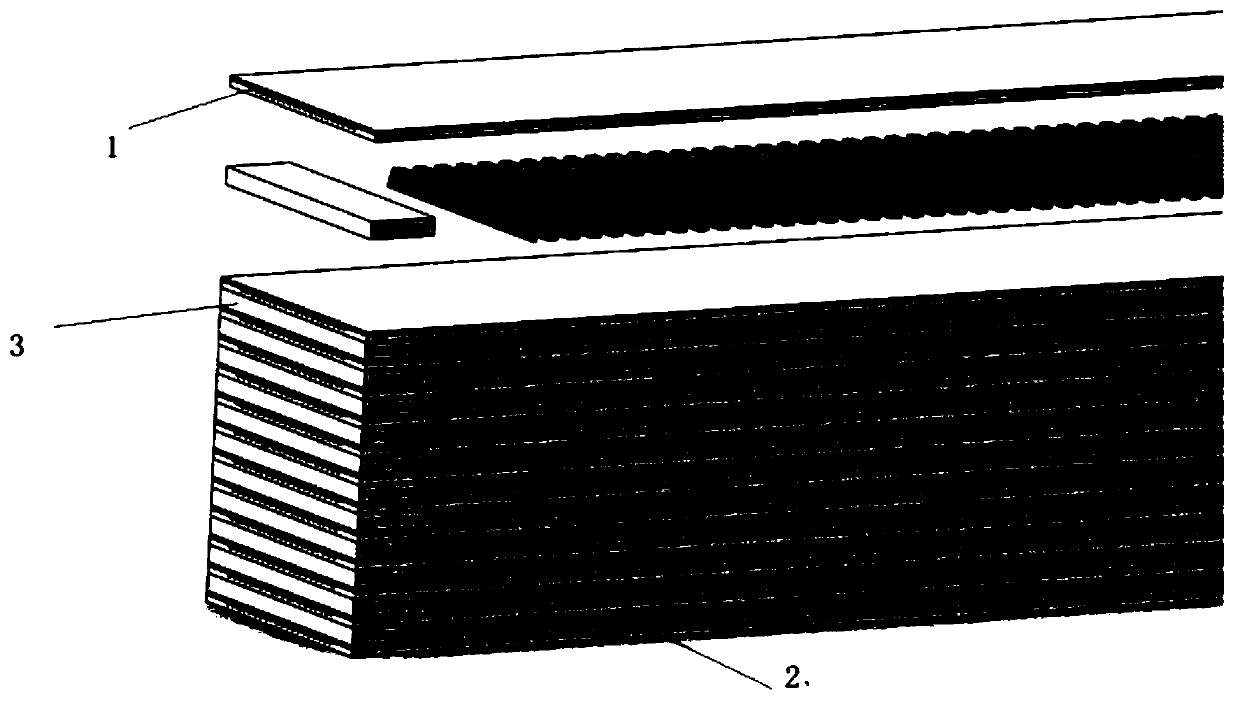

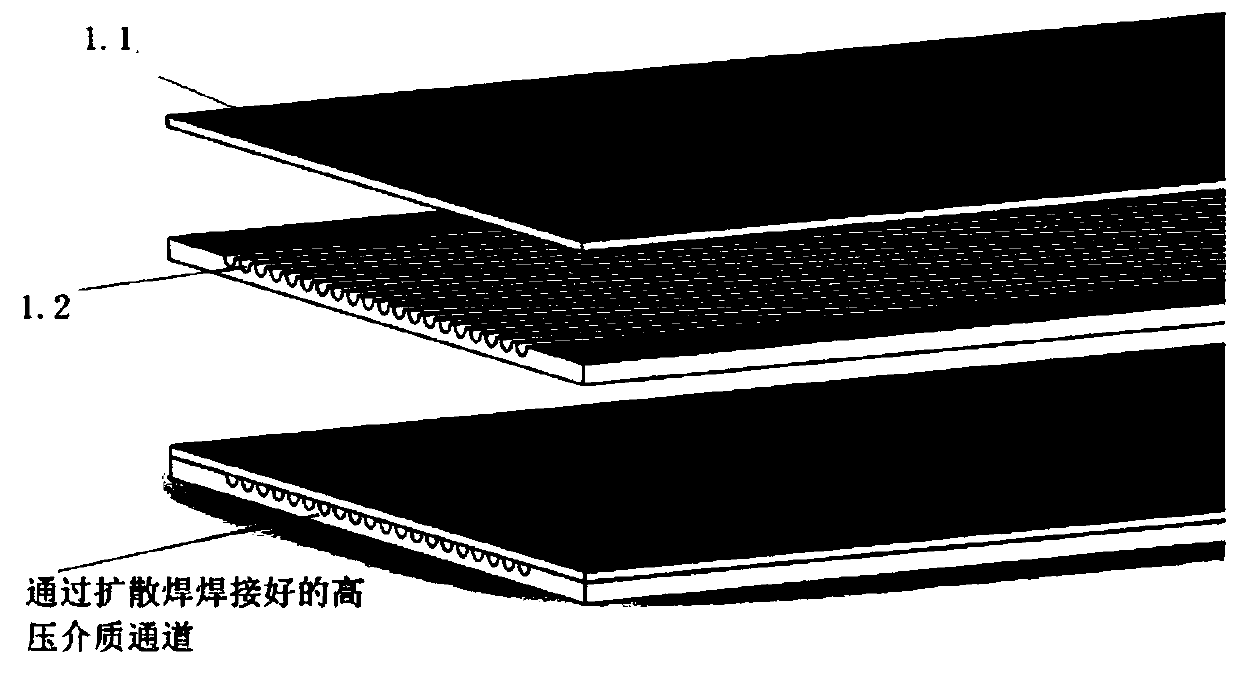

[0023] Such as figure 1 figure 2 image 3 Shown: a printed circuit board air-cooled heat exchanger core, the core is composed of a number of high-pressure medium channels 1, a number of air channels 2, and a number of high-pressure channel head gasket strips 3. The high-pressure medium channel 1 is processed by vacuum diffusion welding process, the air channel 2 can be completed by stamping and other cheap processes, and finally the high-pressure medium channel 1, air channel 2, and high-pressure channel head cushion strip 3 are processed by diffusion welding Technology welded into a whole. The heat exchanger completed by this combined processing not only ensures that the high-pressure medium side channel has sufficient strength and can withstand high pressure, but also ensures that the air side has a sufficient flow area, and avoids a large number of etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com