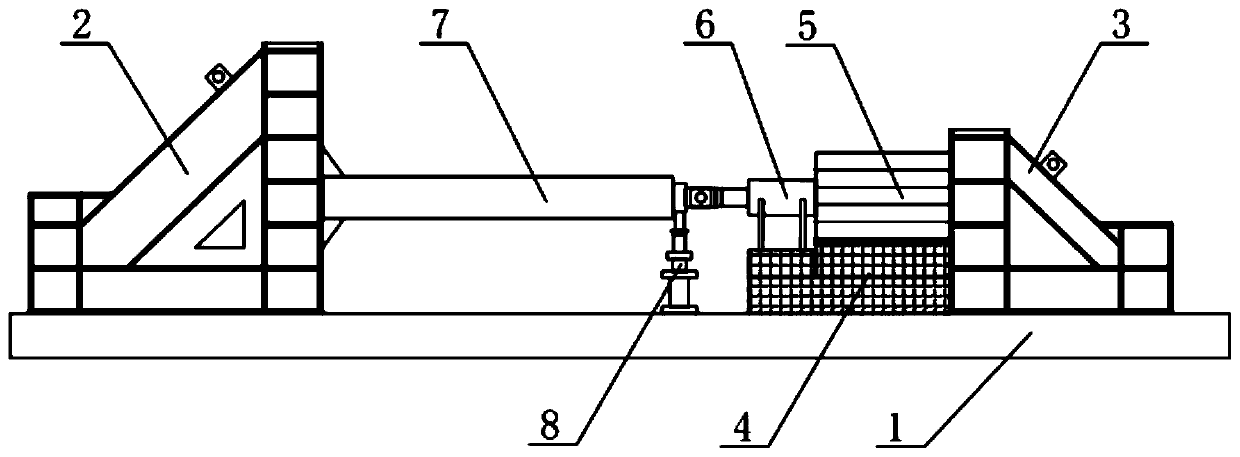

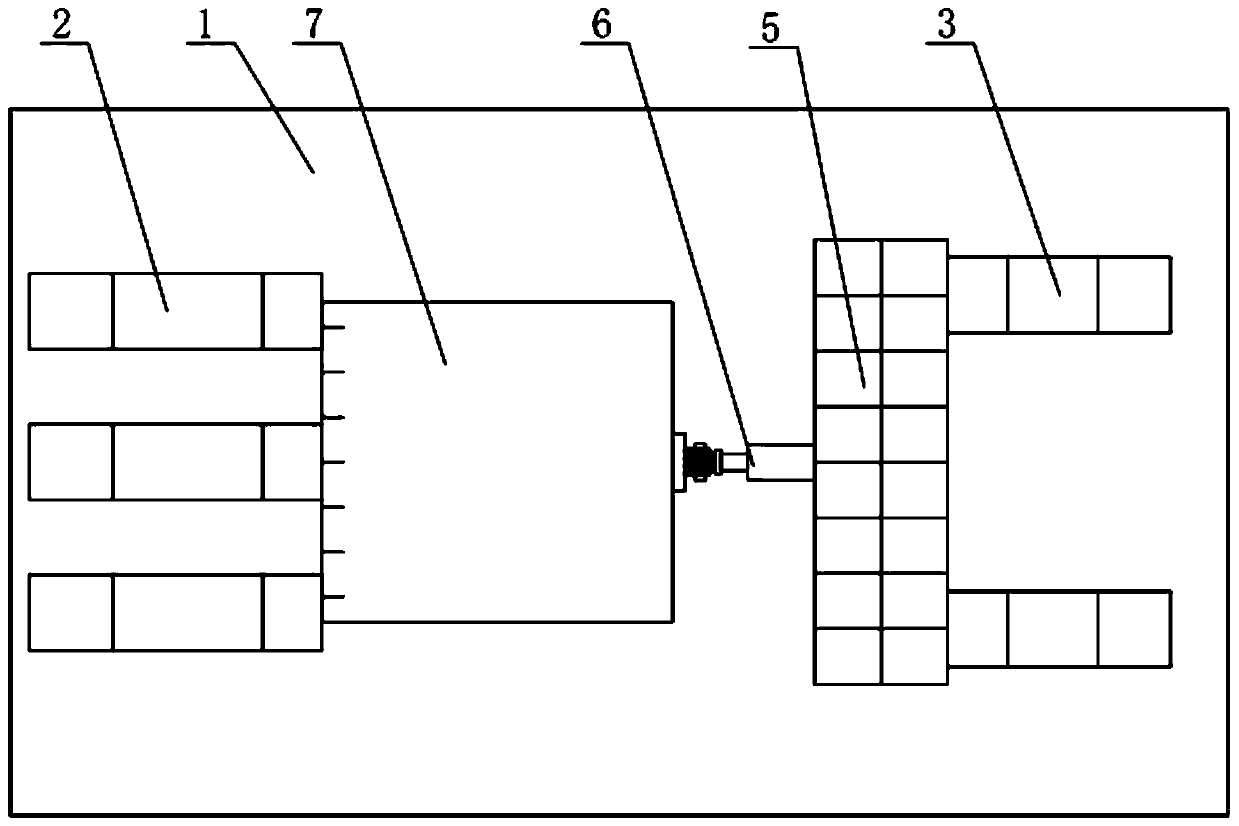

Ultimate strength test device and method for very large floating structure under bending load

A technology of ultimate strength and testing equipment, which is applied in the direction of testing material strength, measuring equipment, and strength characteristics by applying a stable bending force to achieve the effects of easy operation, wide application range, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

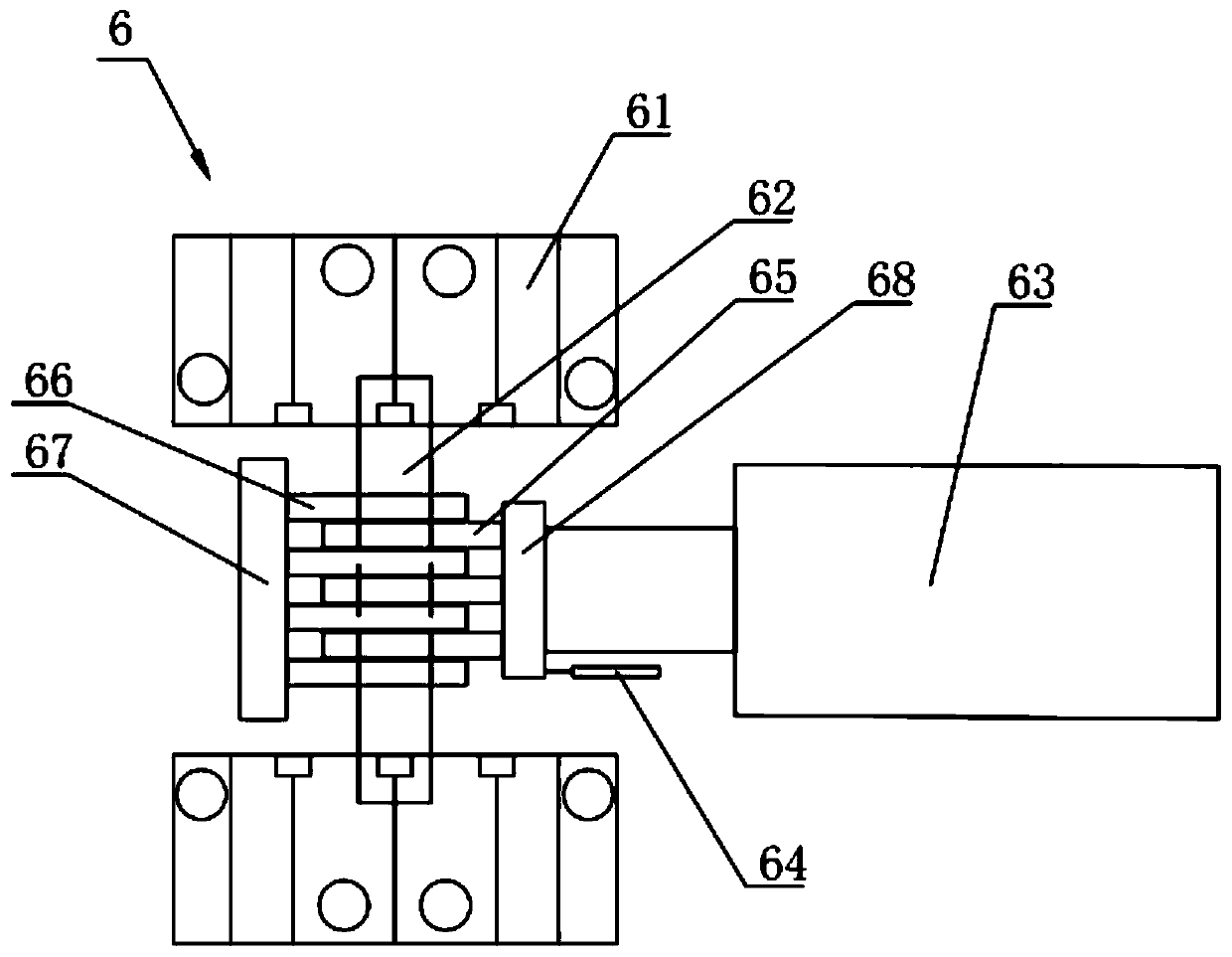

Method used

Image

Examples

Embodiment 1

[0107] Embodiment 1: Take the structural ultimate strength test of the reinforced area of the super-large floating body connector as an example to illustrate;

[0108] like Figure 9 and Figure 10 As shown, it is a schematic diagram of the structure of the connector reinforcement area, which includes a housing 91 with a rectangular structure as a whole and closed on six sides. A protrusion 92 extends from the middle of the front end of the housing 91. A plurality of cross braces 93, one longitudinal brace 94 and two longitudinal braces 95; at the protruding part 92, the connector reinforcement area bears the compressive load and the bending load from the outside.

[0109] Step 1: Determine the similarity relationship between the elastic state and the plastic state;

[0110] The second step: according to the similarity relationship, determine the scale ratio between the prototype and the test model, so as to design the test model according to the first step similarity rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com