Horizontal turntable biological spraying deodorization process and device thereof

A turntable and horizontal technology, applied in the field of horizontal turntable biological spray deodorization system, can solve the key influence of filling layer clogging without considering the total concentration of sludge and suspended solids, without considering activated sludge and fine suspended solids Contribution ratio, blockage of gas-liquid mass transfer channels, etc., to achieve the effects of no chemical consumption, simple configuration, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

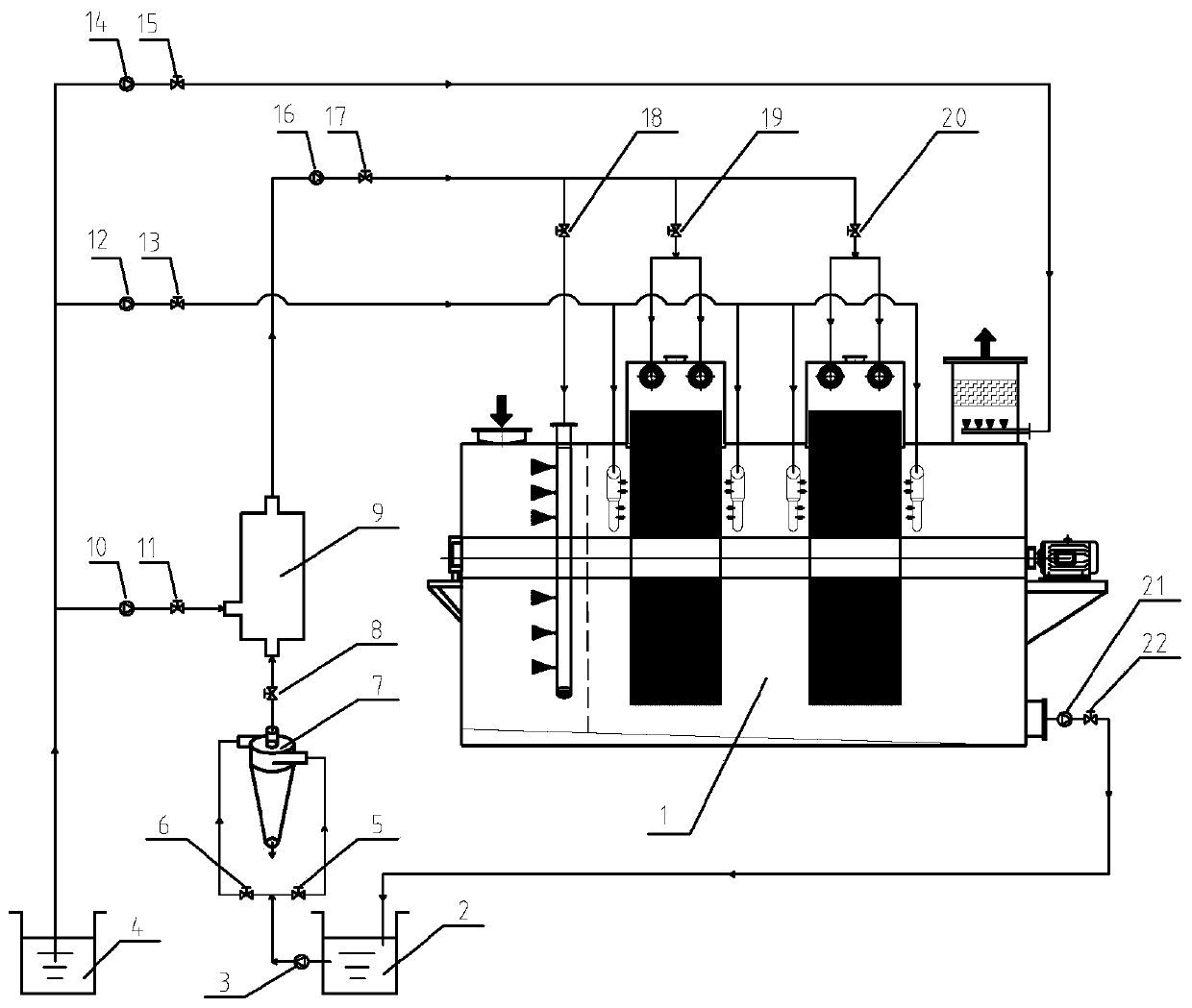

[0046] A horizontal turntable biological spray deodorization process, comprising the following steps:

[0047] S1. Pump the high-slag-containing raw slurry in the return section of the aeration tank or the secondary sedimentation tank into the cyclone separator. The separator can be equipped with one or more stages. Through the action of centrifugal force, firstly use the pulp residue, pulp water and sludge The density difference between them can realize the complete separation of pulp residue and mud-containing slurry, and then use the density difference between slurry water and activated sludge to realize partial separation of slurry water and sludge. After separation, pulp residue and part of sludge It is discharged through the bottom flow port of the cyclone separator and returned to the return section of the aeration tank or the secondary sedimentation tank, and the slurry containing part of the activated sludge flows out through the overflow port at the top of the cyclone...

Embodiment 2

[0069] This example is a comparative example of Example 1, and the structure of the device used is basically the same as that of Example 1. The main difference between the two is that: Example 1 uses a secondary pretreatment process of cyclone separation + slurry dilution, while Example 2 uses a front-end Slurry filter pretreatment process.

[0070] Under the same backwashing conditions of Example 1 and Example 2 (both adopting the secondary sedimentation tank effluent as backwashing water), the change trend of the total pressure drop of the packing layer in the deodorization device before and after backwashing and the comparison of deodorization efficiency are shown in the following table As shown in 1, compared with the front-end pulp and residue filtration pretreatment process, the use of cyclone separation + slurry dilution two-stage pretreatment process has the advantages of thorough removal of pulp and residue, controllable sludge content, efficient and thorough anti-bloc...

Embodiment 3

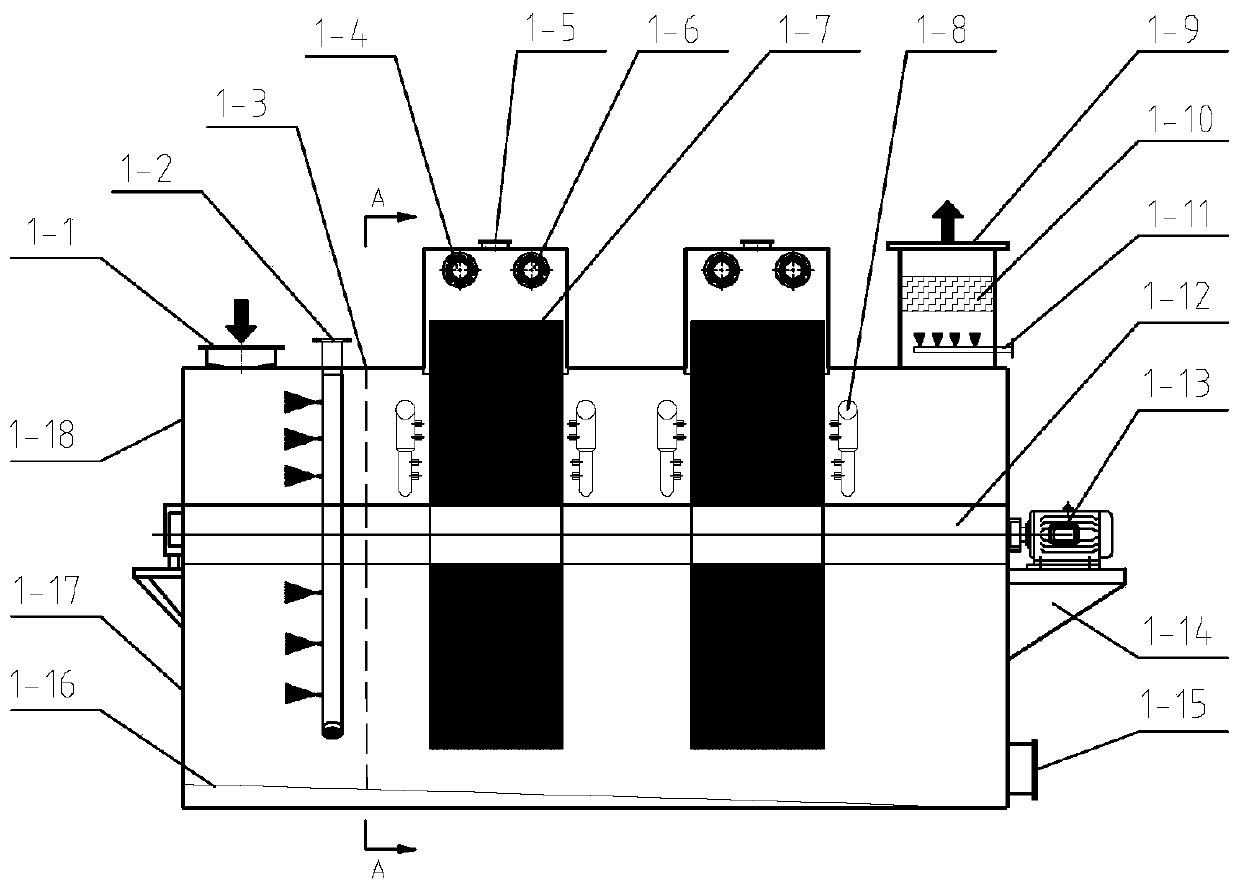

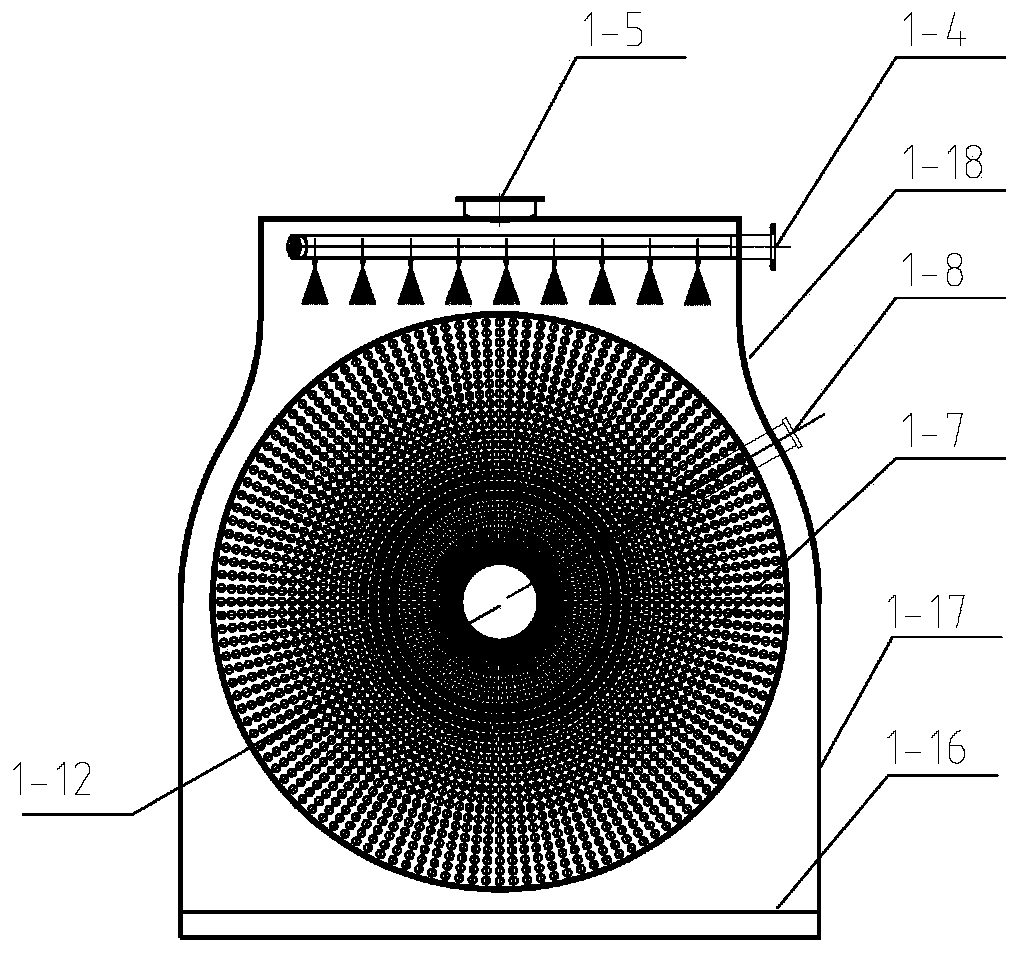

[0074] This example is a comparative example of Example 1. Its process flow and the device structure adopted are basically the same as those of Example 1. The main difference between the two is that: Example 1 adopts the hanging-type hammer combined filler turntable arranged alternately along the radial direction of the turntable. And embodiment 3 adopts traditional gravity filling type spherical packing carousel.

[0075] Under the same backwashing conditions of Example 1 and Example 3 (both using the secondary sedimentation tank effluent as backwashing water), the change trend of the total pressure drop of the packing layer in the deodorization device before and after backwashing and the comparison of deodorization efficiency are shown in the following table As shown in 2, compared with the traditional gravity-filled spherical packing, the use of the chain ball combined packing arranged alternately along the radial direction of the turntable has the advantages of small operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com