Cuprous sulfide material with surface hydrophobicity and preparation method for cuprous sulfide material

A cuprous sulfide, hydrophobic technology, applied in chemical instruments and methods, analytical materials, metal material coating processes, etc., can solve the problems of complex processes, unfavorable hydrophobic surfaces, and many influencing factors, and achieves simple process and low cost. Low, repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

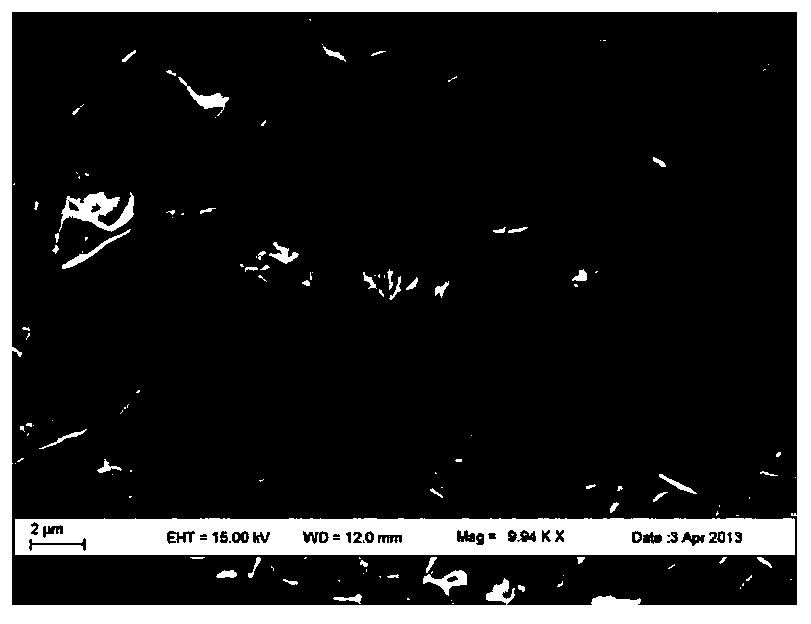

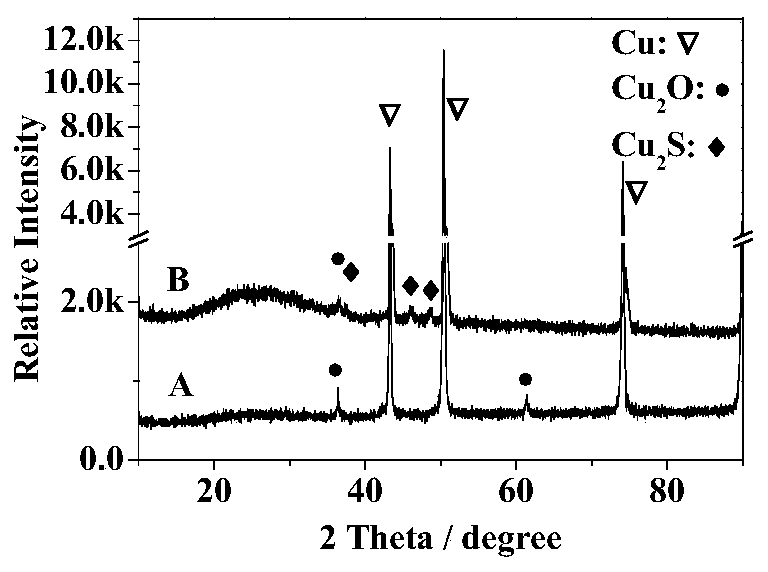

[0039] Prepare a cuprous sulfide flake array with surface hydrophobicity, the specific steps are as follows:

[0040] (1) Take a copper sheet (produced by Shanghai Sinopharm Group, with a thickness of 0.1mm and a purity of 99.9%) as a copper-based material, which is polished with sandpaper, ultrasonically cleaned with deionized water, ultrasonically cleaned with absolute ethanol, and then cleaned with deionized water Clean and dry naturally for later use.

[0041] (2) Place the copper-based material treated in step (1) in 2mol L at 15°C -1 React in a sodium hydroxide solution for 48 hours, take it out, wash it with a large amount of deionized water, and dry it naturally.

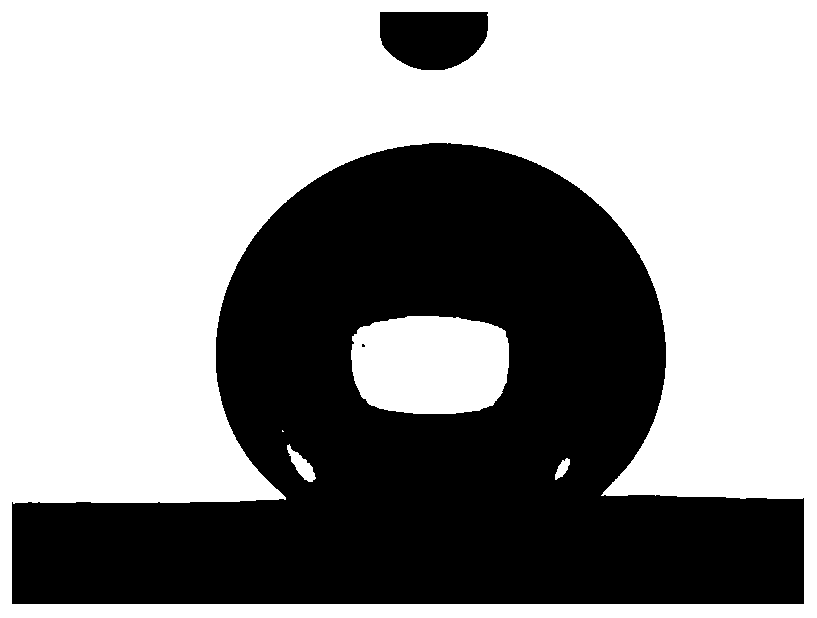

[0042] (3) Place the treated sample in step 2) in 0.2mol L at 17°C -1 React in a sodium sulfide solution for 24 hours, take it out, rinse it with a large amount of deionized water, and dry it with a hair dryer (the static contact angle of the sample to water in air does not exceed 30°).

[0043] (4) Heat th...

Embodiment 2

[0046] Prepare a cuprous sulfide flake array with surface hydrophobicity, the specific steps are as follows:

[0047] (1) Get the copper sheet (produced by Shanghai Sinopharm Group, the thickness is 0.1mm, and the purity is 99.9%) to be the copper-based material, polished with sandpaper, ultrasonically cleaned with deionized water, ultrasonically cleaned with absolute ethanol, and cleaned with deionized water, Let it dry naturally.

[0048] (2) Place the copper-based material treated in step (1) in 2mol L at 15°C -1 React in a sodium hydroxide solution for 48 hours, take it out, wash it with a large amount of deionized water, and dry it naturally.

[0049] (3) Place the treated sample in step 2) in 0.4mol·L at 17°C -1 React in a sodium sulfide solution for 72 hours, take it out, rinse it with a large amount of deionized water, and dry it with a hair dryer (the static contact angle of the sample to water in air does not exceed 30°).

[0050] (4) Heat the sample treated in st...

Embodiment 3

[0053] Prepare a cuprous sulfide flake array with surface hydrophobicity, the specific steps are as follows:

[0054] (1) Get the copper sheet (produced by Shanghai Sinopharm Group, the thickness is 0.1mm, and the purity is 99.9%) to be the copper-based material, polished with sandpaper, ultrasonically cleaned with deionized water, ultrasonically cleaned with absolute ethanol, and cleaned with deionized water, Let it dry naturally.

[0055] (2) Place the copper-based material treated in step (1) in 2mol L at 15°C -1 React in a sodium hydroxide solution for 48 hours, take it out, wash it with a large amount of deionized water, and dry it naturally.

[0056] (3) Place the treated sample in step 2) in 0.6mol·L at 17°C -1 React in a sodium sulfide solution for 72 hours, take it out, rinse it with a large amount of deionized water, and dry it with a hair dryer (the static contact angle of the sample to water in air does not exceed 30°).

[0057] (4) Heat the sample treated in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com