Exposure beam phase measurement method in laser interference lithography and lithography system

A laser interference lithography and phase measurement technology, which is applied in the field of optical instruments and equipment, can solve the difficulty of realizing real-time measurement interference exposure system fringe control, poor anti-interference ability, difficult high-precision measurement, phase solution, subdivision and direction judgment. and other problems, to achieve the effect of real-time measurement, improvement of overall performance, and real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and effects of the present invention for solving technical problems, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the provided accompanying drawings are schematic and mutually exclusive They are not drawn to scale or scale, and therefore the drawings and specific examples are not intended to limit the scope of protection claimed by the invention.

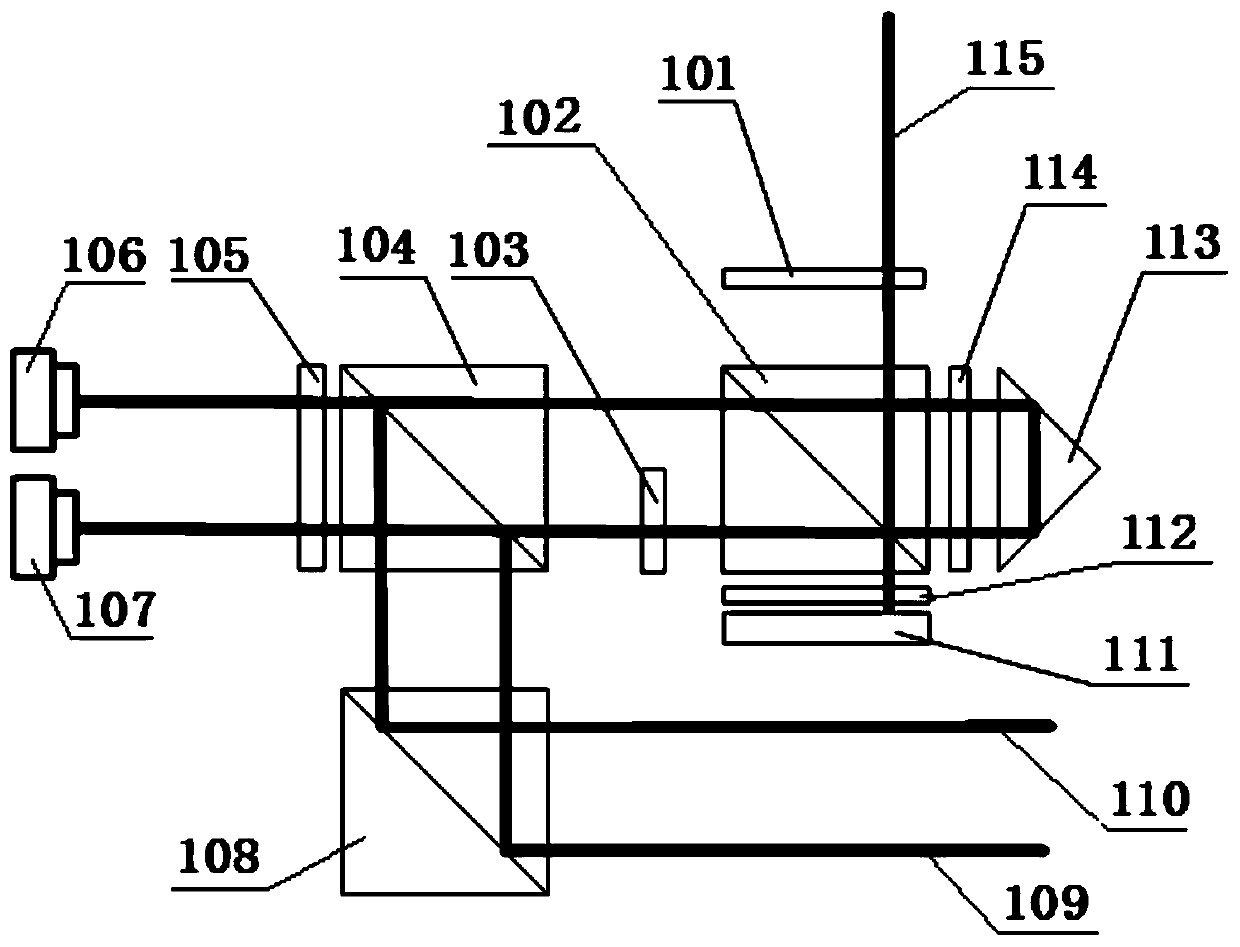

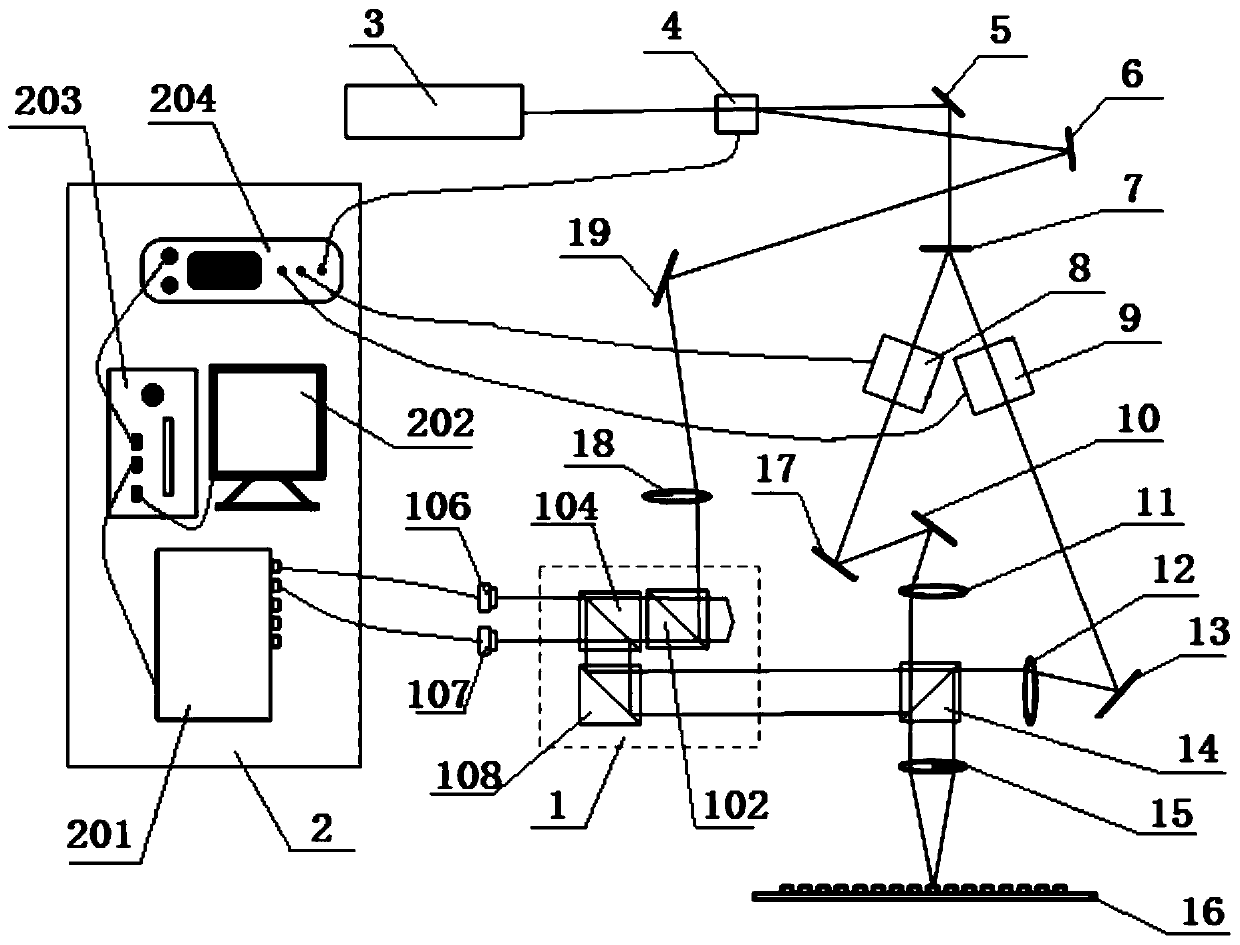

[0029] Such as figure 1 The optical path structure of the laser phase measurement interferometer adopted in the shown method of the present invention comprises a first wave plate 101, a first polarization beam splitter prism 102, a second wave plate 103, a second polarization beam splitter prism 104, a polarizer 105, a first Photodetector 106, the second photodetector 107, the third polarization beam splitter 108 mirror, mirror 111, the third wave plate 112, retr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com