Efficient sterilization method of vacuum circulating ozone

A sterilization method and vacuum cycle technology, which is applied in the field of high-efficiency sterilization of vacuum cycle ozone, can solve the problems of unresearched and low sterilization efficiency, and achieve good sterilization effect and high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

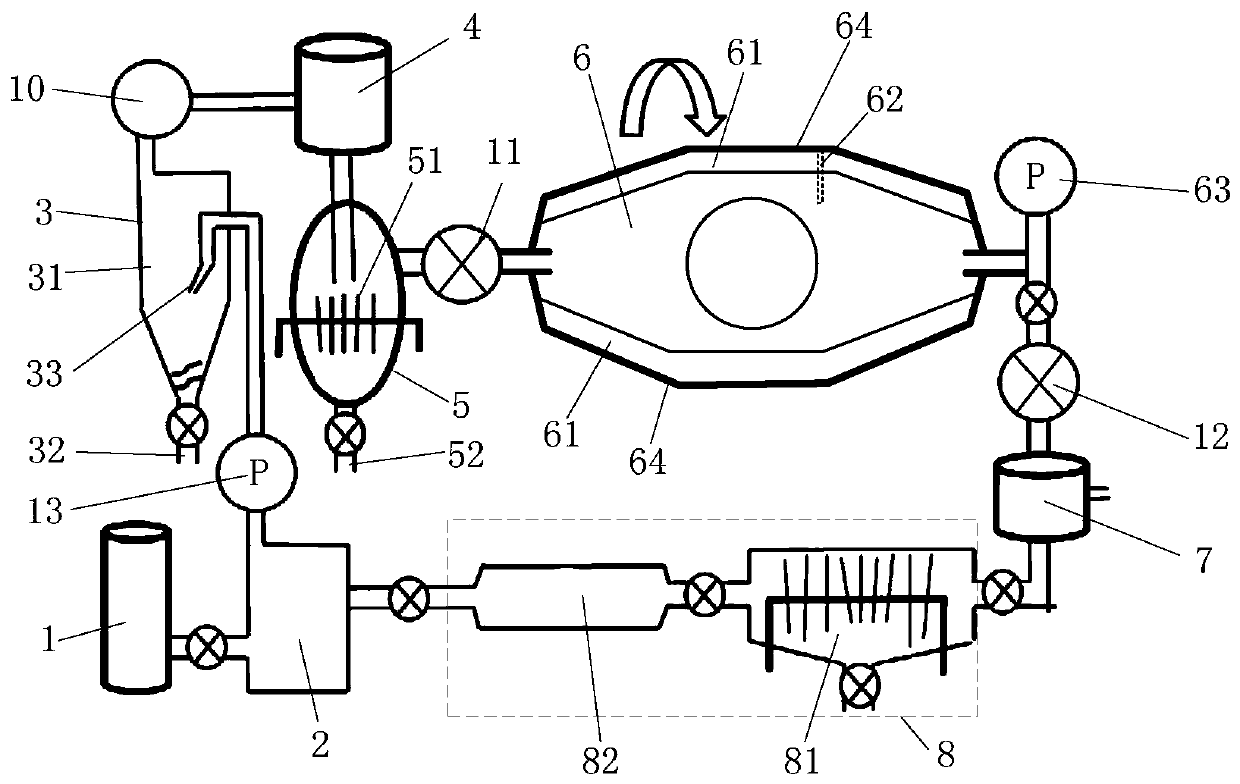

[0032] 1. Refer to figure 1 , the present invention is realized based on a high-efficiency sterilization system of vacuum circulation ozone, and the high-efficiency sterilization system includes an oxygen tank 1, an ozone generator 2, a humidifier 3, a booster pump 4, a temperature-controlled buffer tank 5, Sterilization drum 6, vacuum pump 7 and dehumidification drier 8, described dehumidification drier 8 links to each other with ozone generator 2 again; On the pipeline between described humidifier 3 and described booster pump 4, hygrometer 10 is arranged A first pressure regulating valve 11 is provided on the pipeline connecting the temperature control buffer barrel 5 and the sterilizing drum 6, and a second pressure regulating valve is provided on the pipeline connecting the sterilizing drum 6 and the vacuum pump 7 12;

[0033] The sterilizing drum 6 is rotated, the outer wall of the sterilizing drum 6 is provided with a heater 61, the inside of the sterilizing drum 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com