Magnetorheological sub-aperture polishing device suitable for large-caliber optical elements

A magnetorheological polishing and polishing device technology, which is applied in the direction of optical surface grinders, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of low manufacturing efficiency of optical components, increase the efficiency of magnetorheological polishing, improve Improve processing efficiency and improve the effect of effective processing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

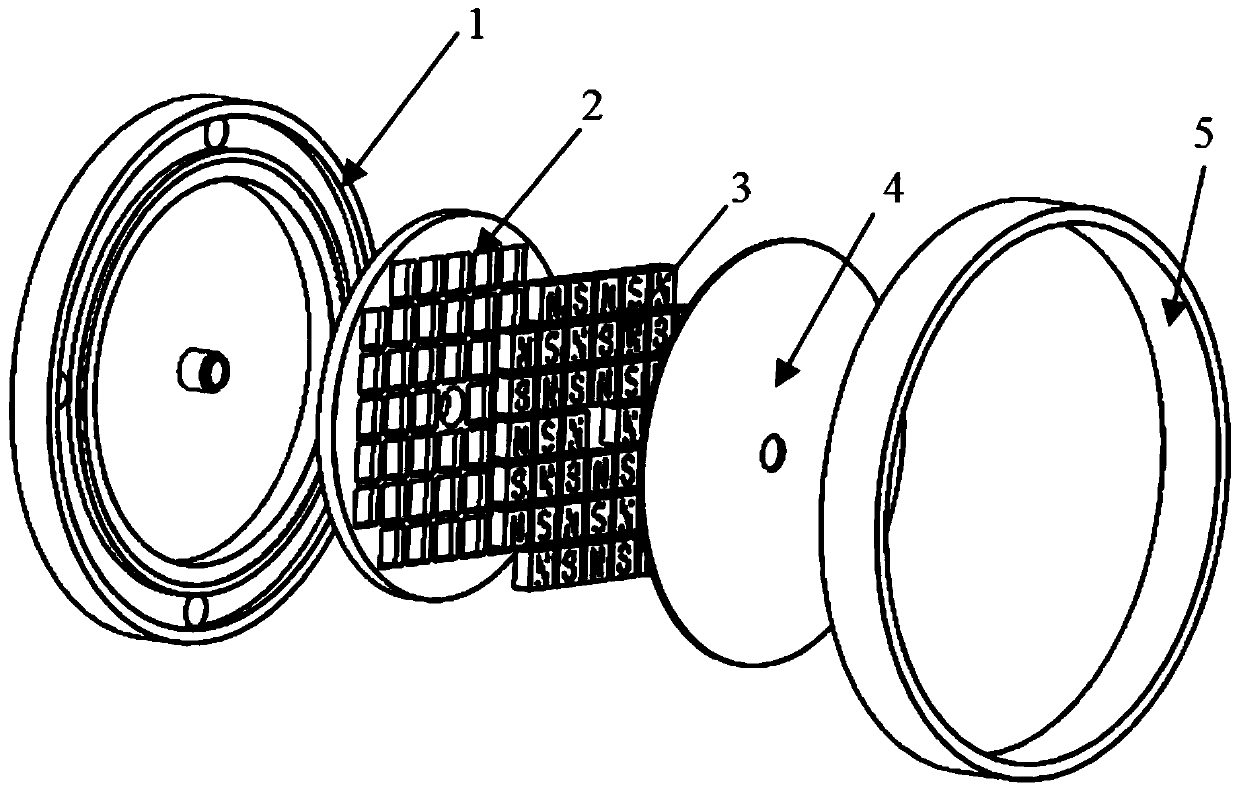

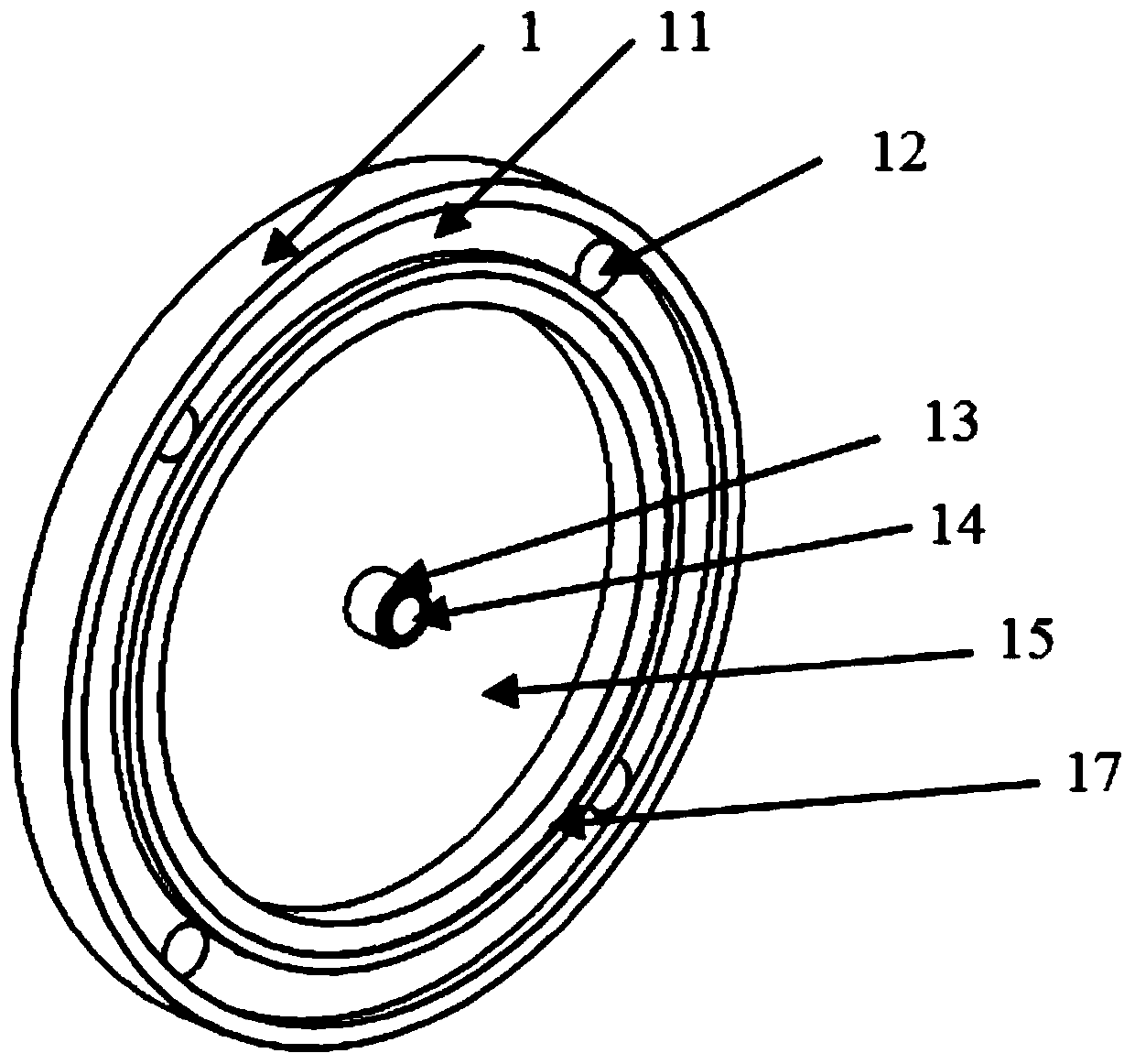

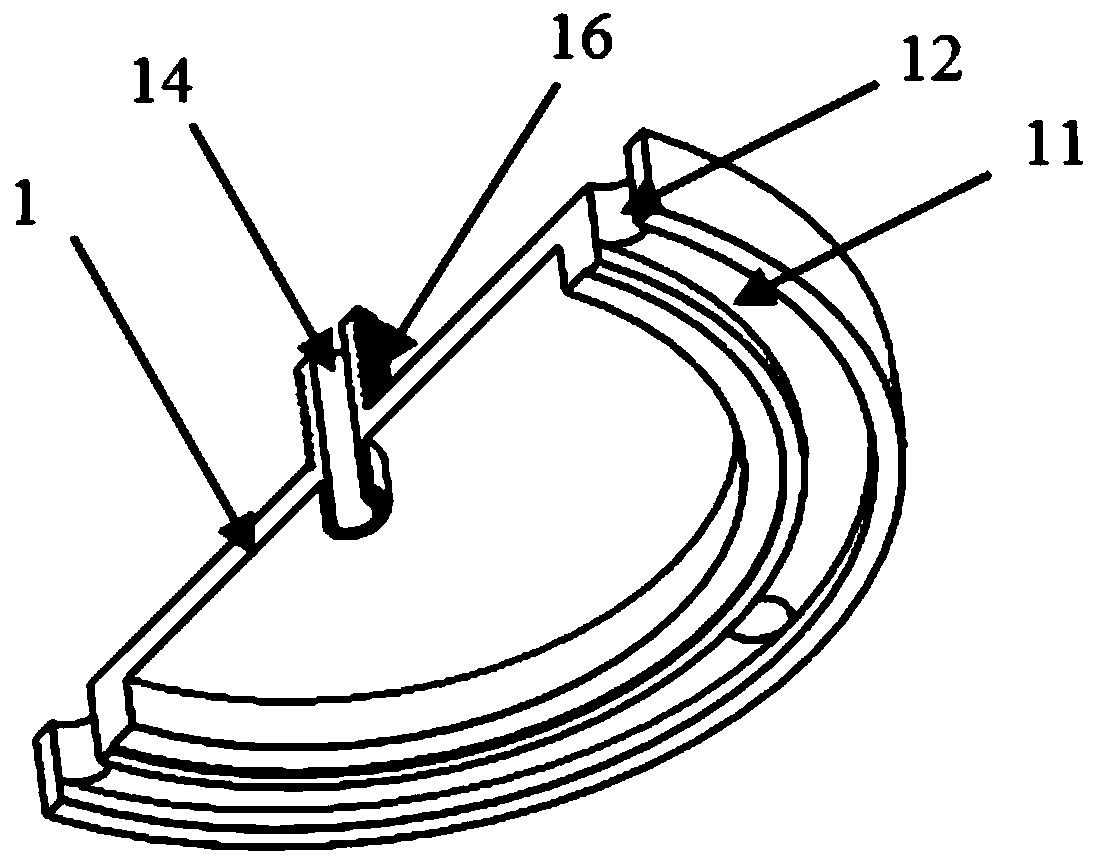

[0029] Specific implementation mode 1: This implementation mode is mainly aimed at flat-plate optical components and optical components with small curvature. Figure 1 to Figure 8 To illustrate this embodiment, as shown in 4, the pure iron back plate 2 is a flat plate, which is embedded into the figure 1 In the annular groove 15 of the main body 1 of the magnetorheological sub-aperture polishing device shown.

[0030] The permanent magnets in the permanent magnet array 3 are embedded in the grooves of the pure iron back plate 2 in a cross arrangement of N poles 31 and S poles 32 , and the magnetic lines of adjacent permanent magnets in the array are closed to form a magnetic field for processing. There is no permanent magnet arrangement at the center 33 of the permanent magnet array, and the permanent magnet can be adsorbed on the pure iron back plate 2 under the action of magnetic force. The groove depth of the pure iron back plate 2 is less than 20% of the thickness of the ...

specific Embodiment approach 2

[0035] Embodiment 2: Embodiment 2 is mainly aimed at large curvature and high steepness optical elements, combined with Embodiment 1 and Figure 9 Describe the second embodiment, the device assembly and use method of the second embodiment is the same as the first embodiment, the difference is that the pure iron back plate 2, the permanent magnet array 3 and the isolation plate 4 need to be changed to have a certain curvature, and the curvature is the same as Pure iron back plate-2-1, permanent magnet array-3-1 and isolation plate-4-1 whose curvature matches the workpiece to be processed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com