Automobile front axle and preparation method thereof

A technology for the front axle and front axle of an automobile, which is applied in the directions of axles, wheels, vehicle parts, etc., can solve the problem that the bending resistance and torsion resistance of the I-beam axle body is not strong enough, it is not suitable for the development trend of light weight, and the length of the axle body cannot be adjusted. and other problems, to achieve the effect of light weight, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

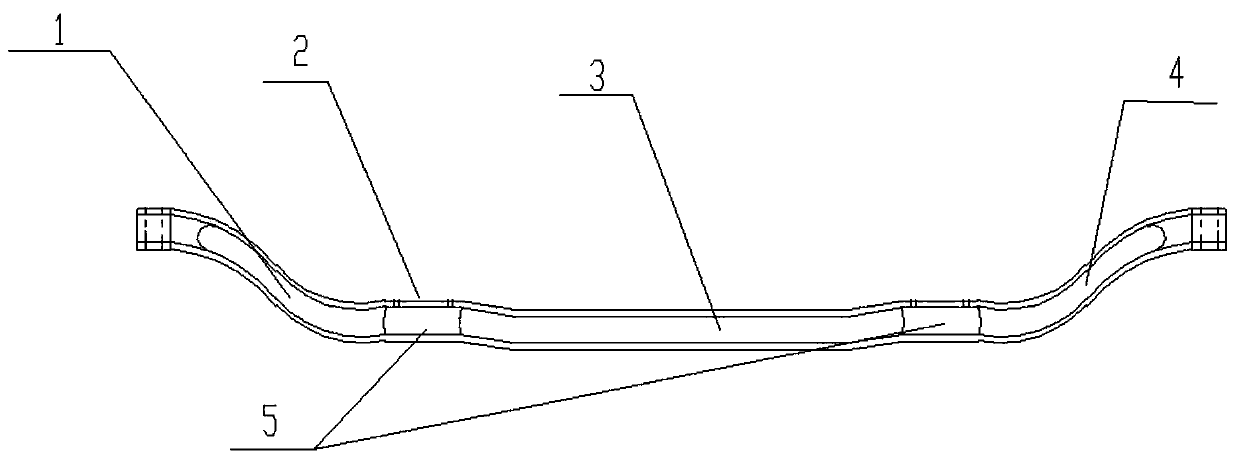

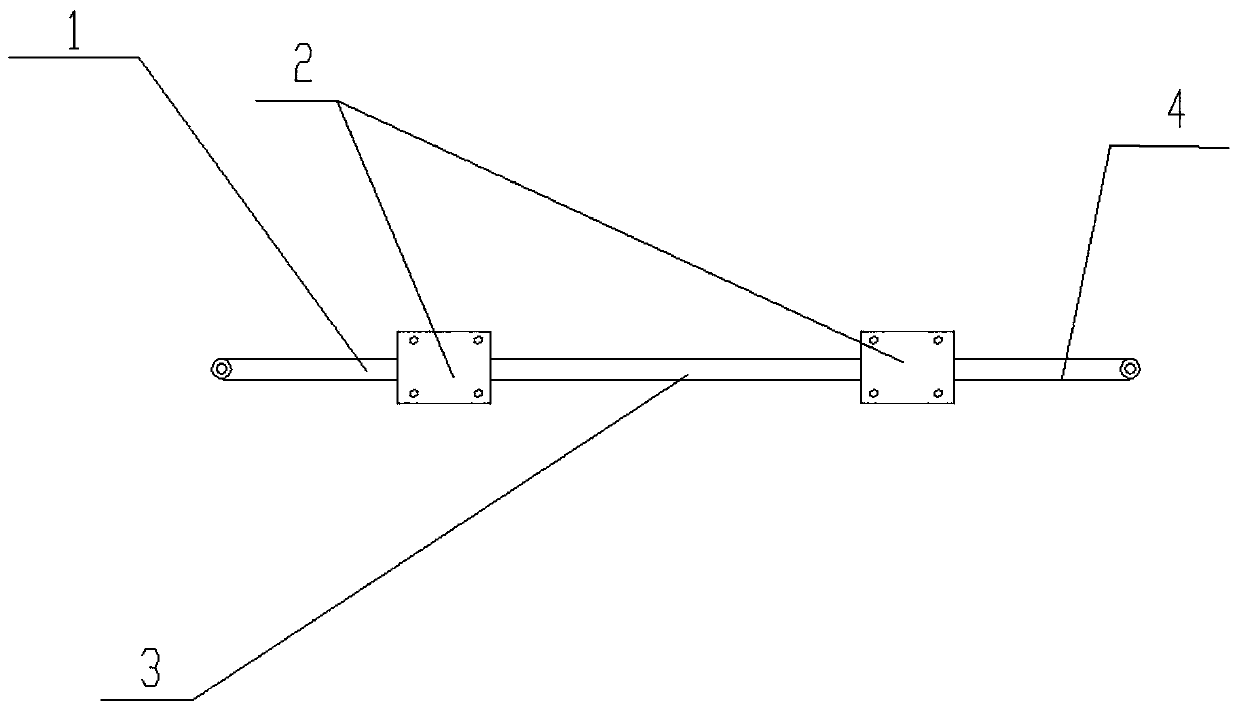

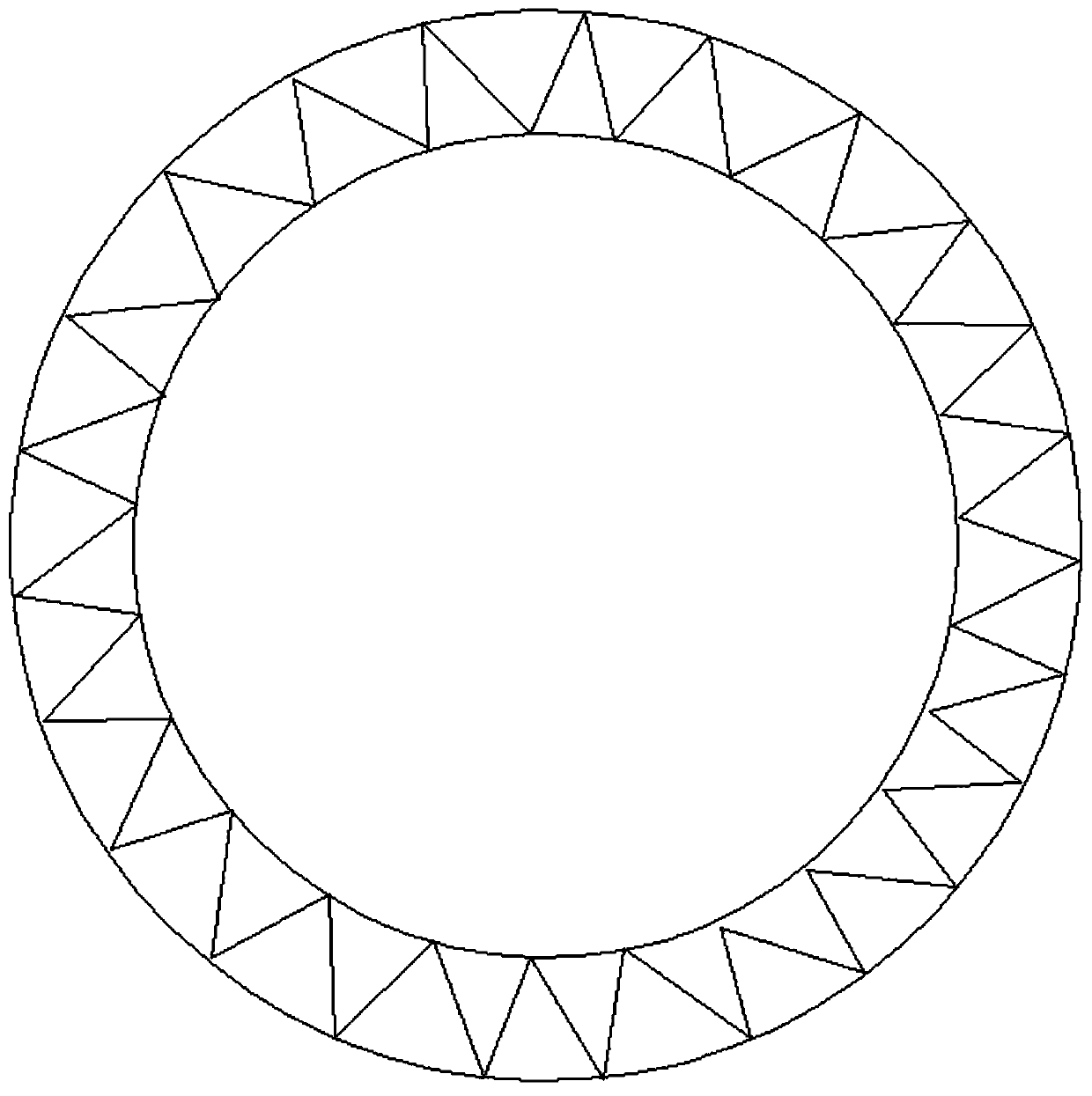

[0036] An automobile front axle, comprising a front axle body (3), a front axle left arm (1), a front axle right arm (4), a steel plate surface (2), overlapping parts (5), a front axle left arm (1), The right arm (4) of the front axle is respectively connected to both ends of the front axle body (3), and the steel plate surface (2) is welded to the upper parts of both ends of the front axle body (3). The front axle body (3) is a hollow structure, and the front axle Both sides of the main body (3) are sunken inwards, and the hollow part of the cross-section of the middle section of the front axle main body (3) is sunken in an I-shape.

[0037] The front axle left arm (1) and the front axle right arm (4) are located in the two ends of the front axle body (3) to form overlapping parts (5).

[0038] The concave position of the middle part of the front axle body (3) starts from the middle position of the front axle body (3) to any position on the side of the central axis of the ove...

Embodiment 2

[0059] Change preparation method parameter among the embodiment 1, concrete method is as follows:

[0060] (1) Cut the 40cr steel circular pipe with a wall thickness of 0.5 cm into 1.3-meter pipe blanks;

[0061] (2) Connect the right arm of the front axle and the left arm of the front axle to the tube blank, and place them in both ends of the tube blank to form overlapping parts;

[0062](3) Connect the overlapped parts through the fixing bolts, the fixing bolts pass through the left arm of the front axle, the right arm of the front axle and the tube blank of the front axle body, and seal the welding edge;

[0063] (4) Heat the front axle of the semi-finished product in step 3 to 850°C, and extrude the middle 1 / 3 of the length of the tube blank of the front axle body inward to form an I-shape;

[0064] (5) Weld the steel plate surface on the upper part of both ends of the front axle body;

[0065] (6) Oil cooling the product in step 5 after being quenched at 850 degrees, te...

Embodiment 3

[0067] (1) Cut 40cr steel elliptical pipe with a pipe wall thickness of 1 cm as raw material into a 1.6-meter pipe blank;

[0068] (2) Connect the right arm of the front axle and the left arm of the front axle to the tube blank, and place them in both ends of the tube blank to form overlapping parts;

[0069] (3) Connect the overlapped parts through the fixing bolts, the fixing bolts pass through the left arm of the front axle, the right arm of the front axle and the tube blank of the front axle body, and seal the welding edge;

[0070] (4) Heat the front axle of the semi-finished product in step 3 to 900°C, and extrude the middle 1 / 2 length of the tube blank of the front axle body inward to form an I-shape;

[0071] (5) Weld the steel plate surface on the upper part of both ends of the front axle body;

[0072] (6) The product in step 5 is oil-cooled after being quenched at 840 degrees, tempered at 570 degrees and air-cooled, and polished after cooling to become the front ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com