Potential load mechanism braking torque detecting system for harbor machine

A braking torque and detection system technology, applied in the field of port machinery, can solve the problems of personal and property safety threats, falling equipment, overturning, etc., and achieve the effects of clear test results, simple operation and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

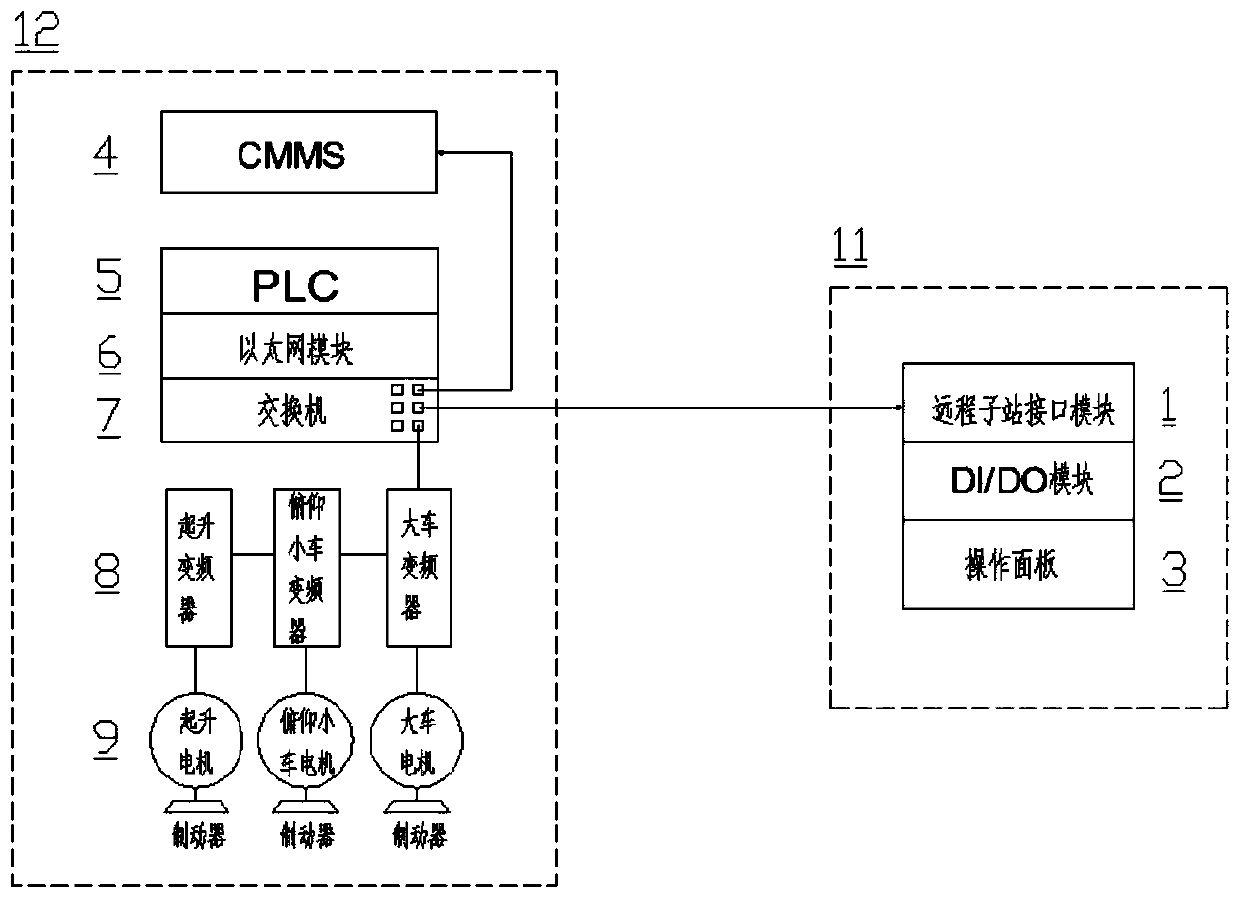

Embodiment 1

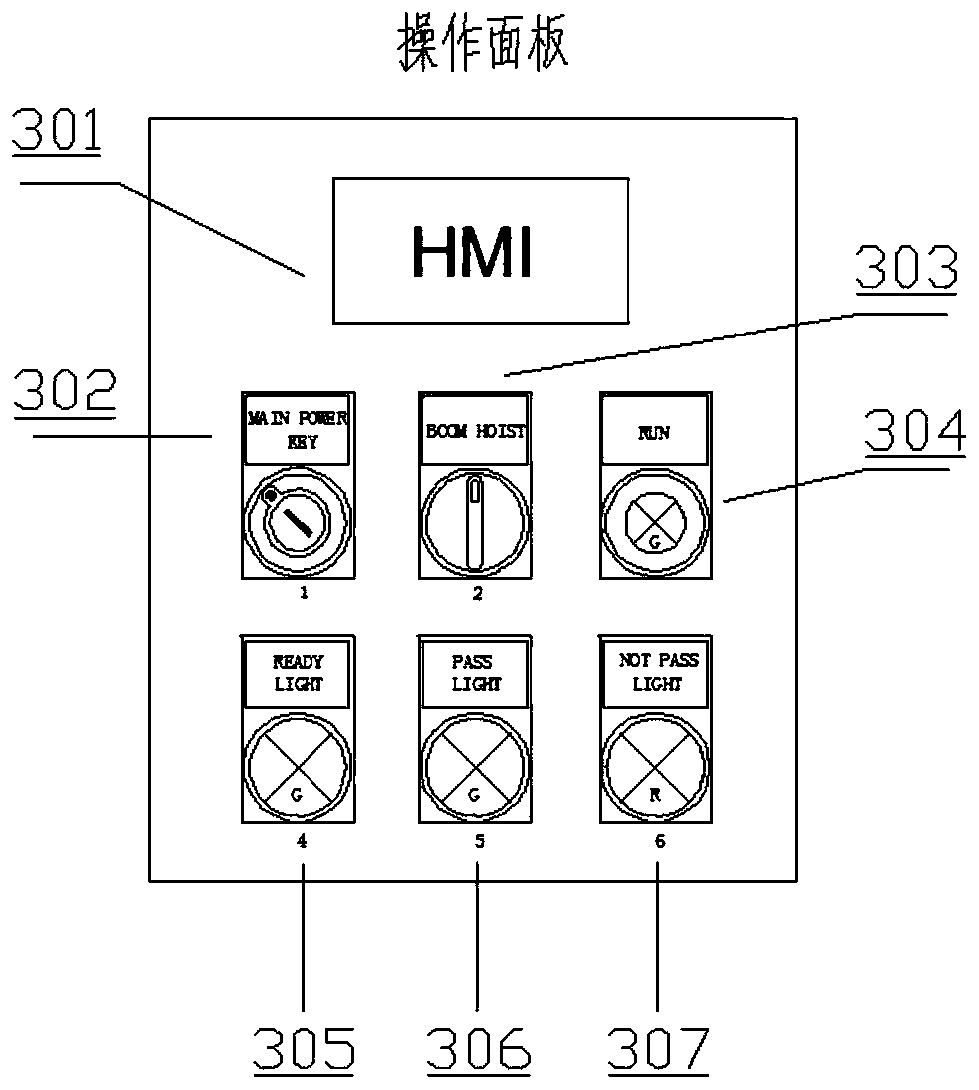

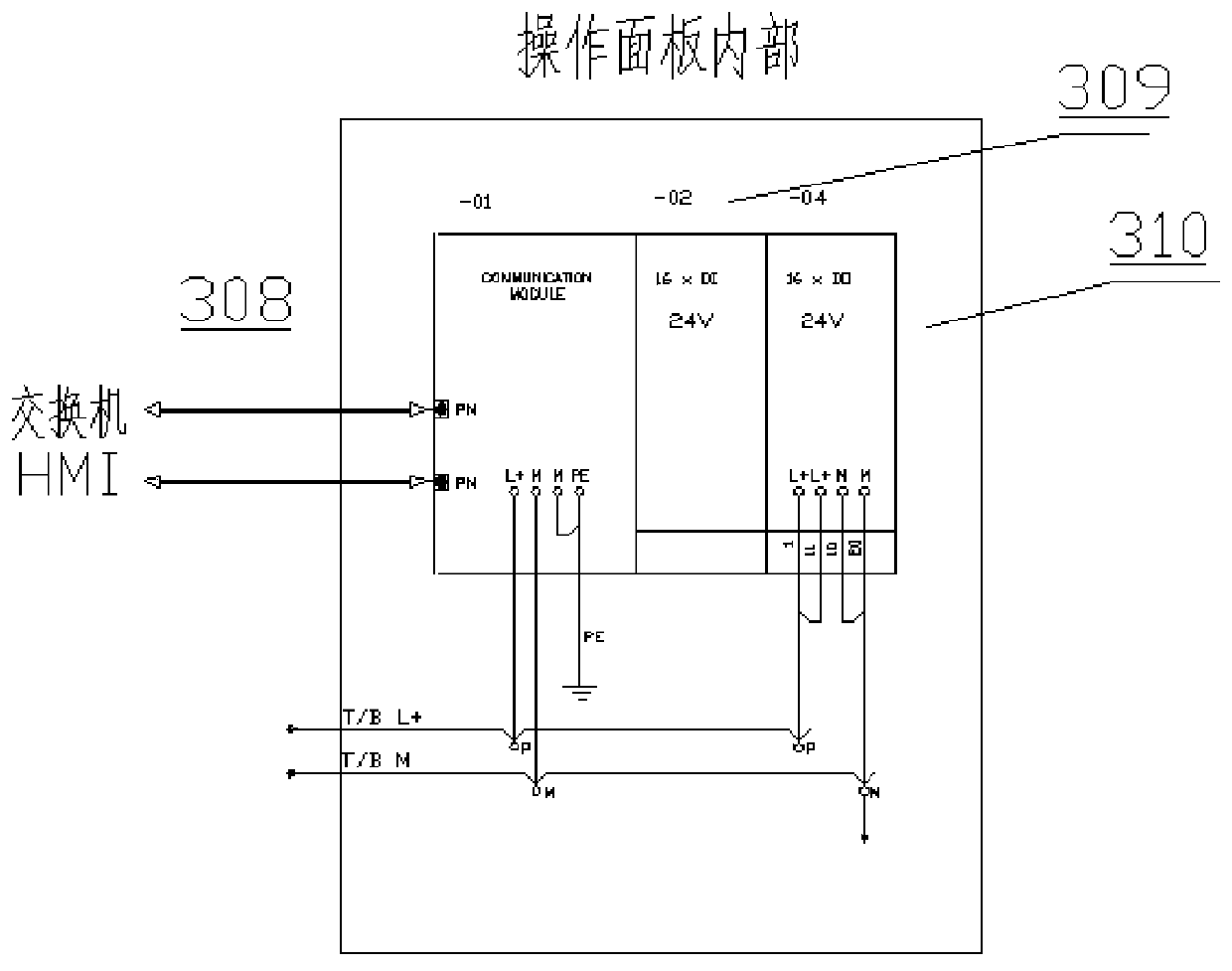

[0042] Taking the port machinery as an example to test the hydraulic brake of the hoisting mechanism of the quay crane by the braking torque detection system of the potential energy load mechanism. The test process is as follows Image 6 Shown: When the system confirms that the current equipment trolley is anchored and the hoisting wire rope is in a loose state, the ready condition indicator light 305 of the operation panel 3 in the operation terminal 11 will be always on, otherwise it is necessary to check and adjust the equipment to enter the maintenance position; The personnel choose to enter the test mode through the key switch 302, point the mechanism selection switch 303 to the hoisting mechanism, then select the hoisting safety brake on the HMI301, and set parameters such as motor torque limit and motor speed. The parameter data is transmitted to the host PLC control system 12 through Ethernet, that is, the PLC 5 receives the parameter data from the operation terminal 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com