Polyester polyol as well as preparation method and application

A polyester polyol and polyol technology, applied in the field of polyurethane materials, can solve the problems of long synthesis steps, product flexibility, low temperature resistance and mechanical properties, and increase the difficulty of synthesis process control, so as to improve hardness and synthesis Simple method, convenient and efficient synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

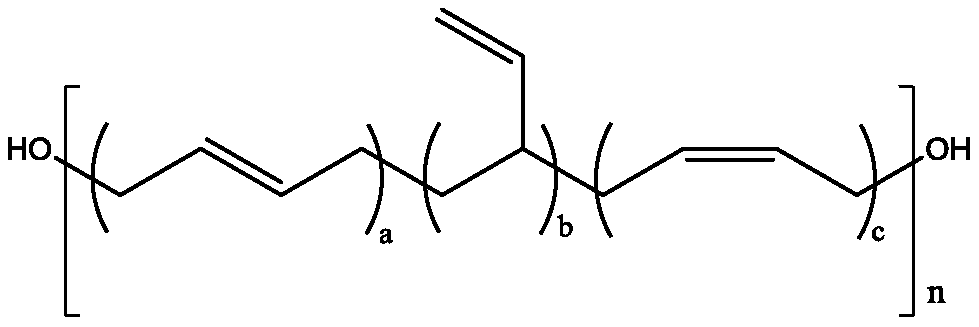

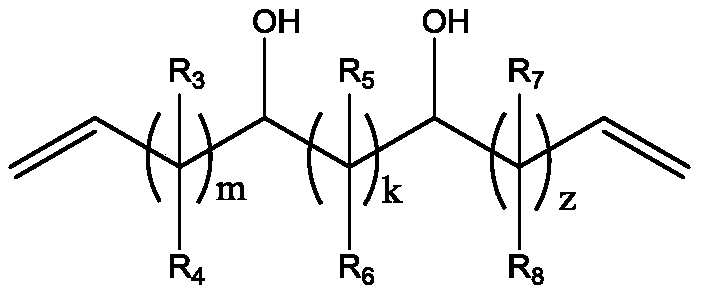

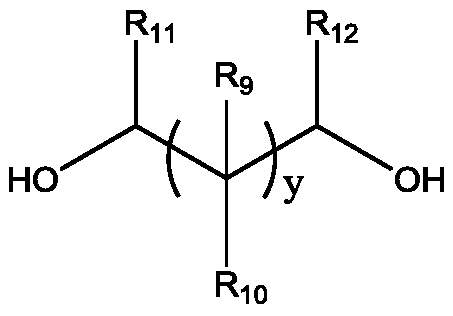

Method used

Image

Examples

Embodiment 1-12

[0052] A kind of preparation method of polyester polyol, the raw material that adopts and proportioning reference table 1;

[0053] The overall preparation process is: in a 5L stainless steel reaction kettle equipped with heating jacket, stirring, nitrogen stripping, rectification tower, vacuum gauge, and alcohol recovery tank, according to Table 1, components A, B, C and polymerization inhibition agent. Heat up to 145°C to melt and start the reaction. As the reaction progresses, the by-product water is continuously separated from the system, and the reaction stage lasts for 1 hour. Subsequently, the temperature was further raised to 250° C. for 3 hours. After 1 hour of heat preservation at 250°C, the reaction water gradually slowed down. At this time, tetra-n-butyl titanate was added, and the vacuum degree was increased to 0.09MPa within 1 hour to continue the reaction. The reaction stops when the value reaches the set value. Cool down to 150°C, discharge and pack. The ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com