A kind of modified EPDM rubber and preparation method thereof

A modification technology of EPDM rubber, which is applied in the field of modified EPDM rubber and its preparation, can solve the problems of difficult vulcanization of EPDM rubber, low production efficiency, long reaction time, etc., and achieve a favorable vulcanization process , vulcanization speed increase, the effect of high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

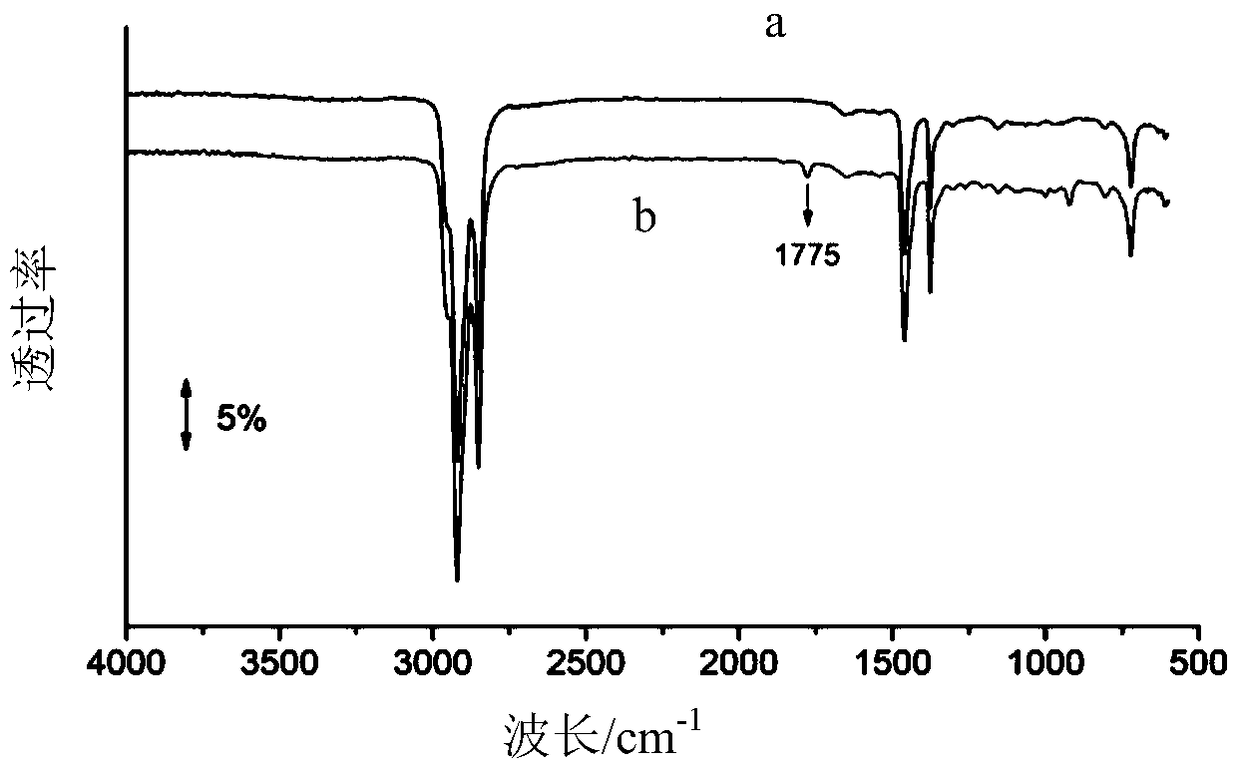

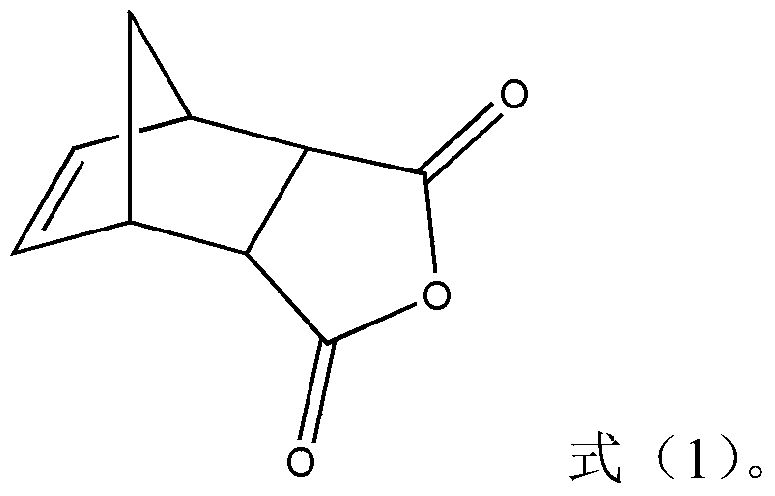

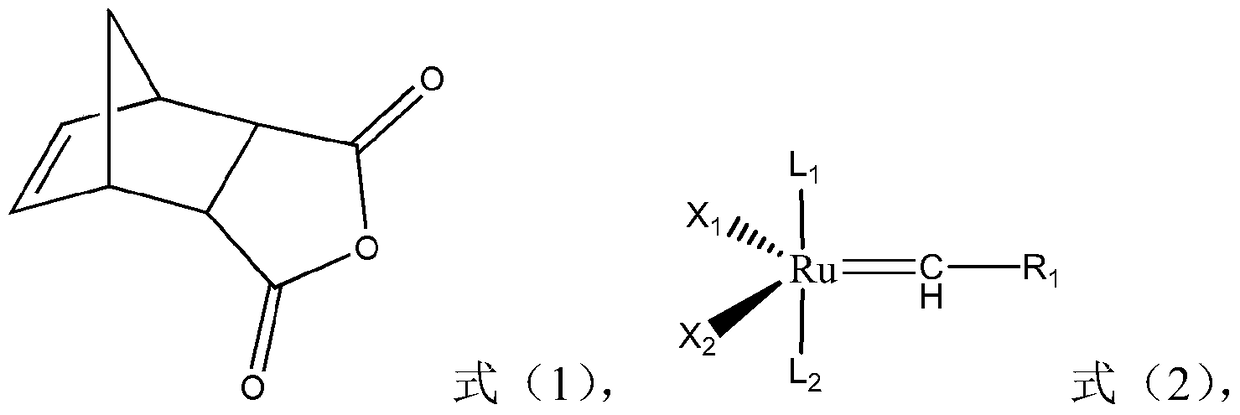

[0030] According to the present invention, preferably, the preparation method of the modified EPDM rubber comprises: under the ring-opening cross-metathesis reaction conditions of olefins, in the presence of a catalyst having a structure shown in formula (2), EPDM The nadic acid anhydride of rubber and structure shown in formula (1) contacts in organic solvent,

[0031]

[0032] In formula (2), R 1 hydrogen, C2-C20 alkenyl, C2-C20 alkynyl, C1-C20 alkyl, C6-C20 aryl, C2-C20 carboxylate, C1-C20 alkoxy, C2- C20 alkenyloxy, C2-C20 alkynyloxy, C6-C20 aryloxy, C1-C20 alkylthio, C1-C20 alkylsulfonyl or C1-C20 alkylsulfinyl,

[0033] x 1 and x 2 are independently anionic ligands,

[0034] L 1 and L 2 each independently is a neutral ligand, and optionally L 1 and L 2 A neutral ligand capable of interconnecting to form two coordinates.

[0035] In formula (2), R 1 It is preferably a C6-C20 aryl group, more preferably a phenyl group.

[0036] In formula (2), X 1 and x 2 I...

preparation example 1

[0117] This preparation example is used to illustrate the preparation method of Nadic anhydride of structure shown in formula (1).

[0118] Add 15.7 grams (0.16 mol) of maleic anhydride and 40 mL of toluene to a 100 mL reaction flask, place the reaction flask in a constant temperature cold bath, stir and cool to 5°C, and add cyclopentadiene 14 dropwise through a constant pressure dropping funnel. gram (0.2mol), control the temperature in the reaction bottle not to exceed 15°C, after the dropwise addition, raise the reaction temperature to 120°C and continue to stir for 1 hour, cool and precipitate white crystals, filter out the crude Nadic anhydride, and then recrystallize with toluene , filtered and dried to obtain 19.0 g of Nadic anhydride, the melting point (mp) of Nadic anhydride was 165.8°C-167°C, and the yield was 72.3%.

Embodiment 1

[0120] This example is used to illustrate the modified EPDM rubber provided by the present invention and its preparation method.

[0121] With 8 grams of EPDM rubber (3280, purchased from Yanshan Petrochemical Company, the content of ethylene structural unit in EPDM rubber is 55% by weight, the content of the third monomer is 5% by weight, and the weight average molecular weight is 300,000 , the third monomer is 5-ethylidene-2-norbornene (ENB)), 1 gram of Nadic anhydride prepared in Preparation Example 1 in N 2 Under protection, dissolve in 90mL xylene solution until completely dissolved to form a reaction system; at the same time, weigh 0.05g of the catalyst with the structure shown in formula (5) (commercially purchased from Bailingwei Technology Co., Ltd., the same below), and dissolve it in 10mL di in toluene solution to obtain catalyst solution C1.

[0122] Heat the obtained reaction system to 70°C, add 2mL of catalyst solution C1 to the reaction system first, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com