Biomass pretreatment agent and preparation method thereof

A pretreatment agent and biomass technology, applied in the direction of dry-cleaning fiber products, textiles and papermaking, etc., can solve the problems of increasing processing and changing fiber properties, and achieve the effects of convenient removal, simplified process and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

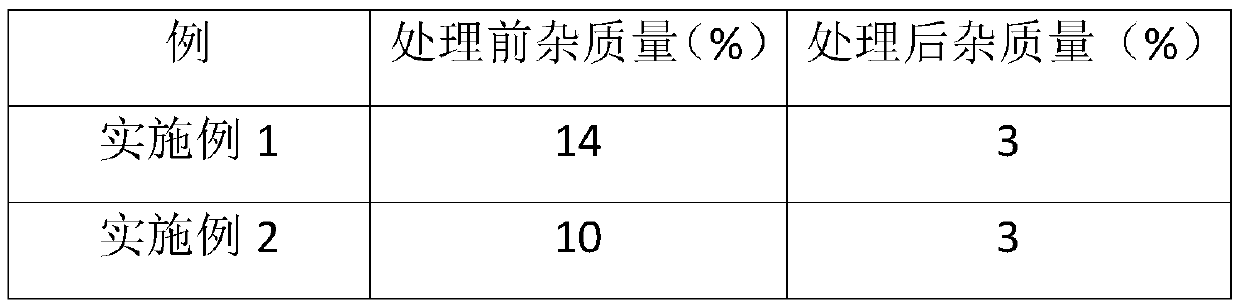

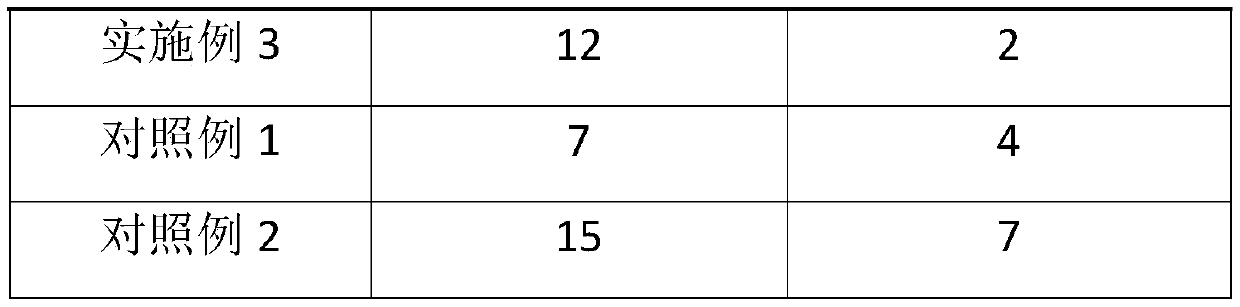

Examples

Embodiment 1

[0040] The invention discloses a biomass pretreatment agent, which comprises the following components according to important parts: 5 parts of soda ash, 5 parts of emulsifier, 3 parts of natural saponin, 10 parts of ethanol, 1 part of biomass essence, and 3 parts of amino acid , 3 parts of thickener, 30 parts of water.

[0041] The present invention also provides a kind of preparation method of biomass pretreatment agent, and concrete steps comprise:

[0042] Step 1: Add 5 parts of soda ash and 30 parts of water into the reaction kettle, and stir at 500-1000 rpm for 10 minutes.

[0043] Step 2, add 10 parts of ethanol, 1 part of biomass essence, 500-1000 rpm, and stir for 10 minutes;

[0044] Step 3, add 5 parts of emulsifier, 500-1000 rpm, stir for 10-20 minutes;

[0045] Step 4, add 3 parts of amino acid, 3 parts of natural saponin, 500-1000 rpm, stir for 5-10 minutes;

[0046] Step 5, 3 parts of thickener, 500-1000 rpm, stirring for 5-10 minutes;

[0047] Step 6, stop s...

Embodiment 2

[0050] The invention discloses a biomass pretreatment agent, which comprises the following components according to the important parts: 6 parts of soda ash, 6 parts of emulsifier, 4 parts of natural saponin, 13 parts of ethanol, 1 part of biomass essence, and 4 parts of amino acid , 4 parts of thickener, 40 parts of water.

[0051] The present invention also provides a kind of preparation method of biomass pretreatment agent, and concrete steps comprise:

[0052] Step 1: Add 6 parts of soda ash and 40 parts of water into the reaction kettle, and stir at 500-1000 rpm for 10 minutes.

[0053] Step 2, add 13 parts of ethanol, 1 part of biomass essence, 500-1000 rpm, and stir for 10 minutes;

[0054] Step 3, add 6 parts of emulsifier, 500-1000 rpm, stir for 10-20 minutes;

[0055] Step 4, add 4 parts of amino acid, 4 parts of natural saponin, 500-1000 rpm, stir for 5-10 minutes;

[0056] Step 5, 4 parts of thickener, 500-1000 rpm, stirring for 5-10 minutes;

[0057] Step 6, st...

Embodiment 3

[0060] The invention discloses a biomass pretreatment agent, which comprises the following components according to the important parts: 7 parts of soda ash, 7 parts of emulsifier, 5 parts of natural saponin, 15 parts of ethanol, 2 parts of biomass essence, and 5 parts of amino acid , 5 parts of thickener, 50 parts of water.

[0061] The present invention also provides a kind of preparation method of biomass pretreatment agent, and concrete steps comprise:

[0062] Step 1: Add 7 parts of soda ash and 50 parts of water into the reaction kettle, and stir at 500-1000 rpm for 10 minutes.

[0063] Step 2, add 15 parts of ethanol, 2 parts of biomass essence, 500-1000 rpm, and stir for 10 minutes;

[0064] Step 3, add 7 parts of emulsifier, 500-1000 rpm, stir for 10-20 minutes;

[0065]Step 4, add 5 parts of amino acids, 5 parts of natural saponin, 500-1000 rpm, and stir for 5-10 minutes;

[0066] Step 5, 5 parts of thickener, 500-1000 rpm, stirring for 5-10 minutes;

[0067] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com