Sample sealing and vacuum transferring device for cross-platform connection

A transfer device and cross-platform technology, applied to measurement devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as time-consuming, randomness in the selection and analysis of samples to be observed, and inaccurate analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. For the detailed description of these embodiments, it should be understood that those skilled in the art can practice the present invention, and can use other embodiments without departing from the spirit of the appended claims and the scope of the present invention. Modifications and / or changes are made to the examples shown. Furthermore, although specific features of the present invention have been disclosed in the embodiments, such specific features can be properly modified to achieve the functions of the present invention.

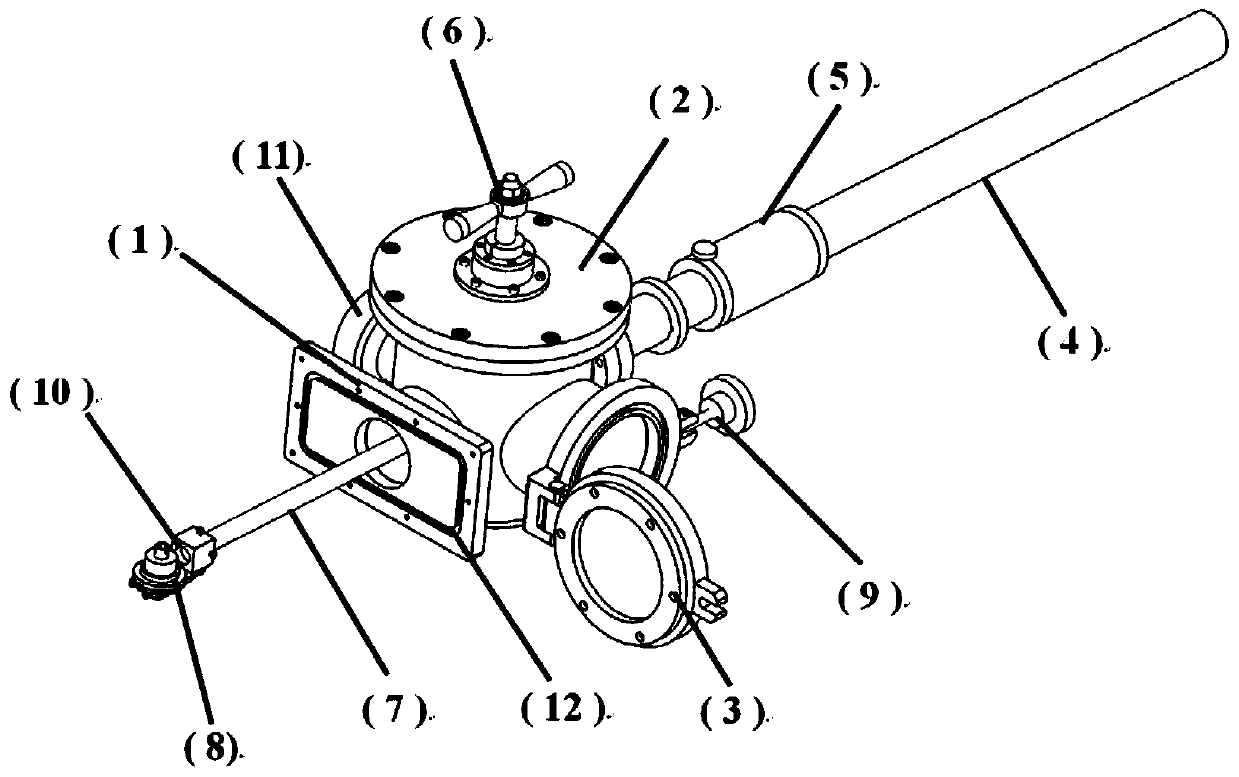

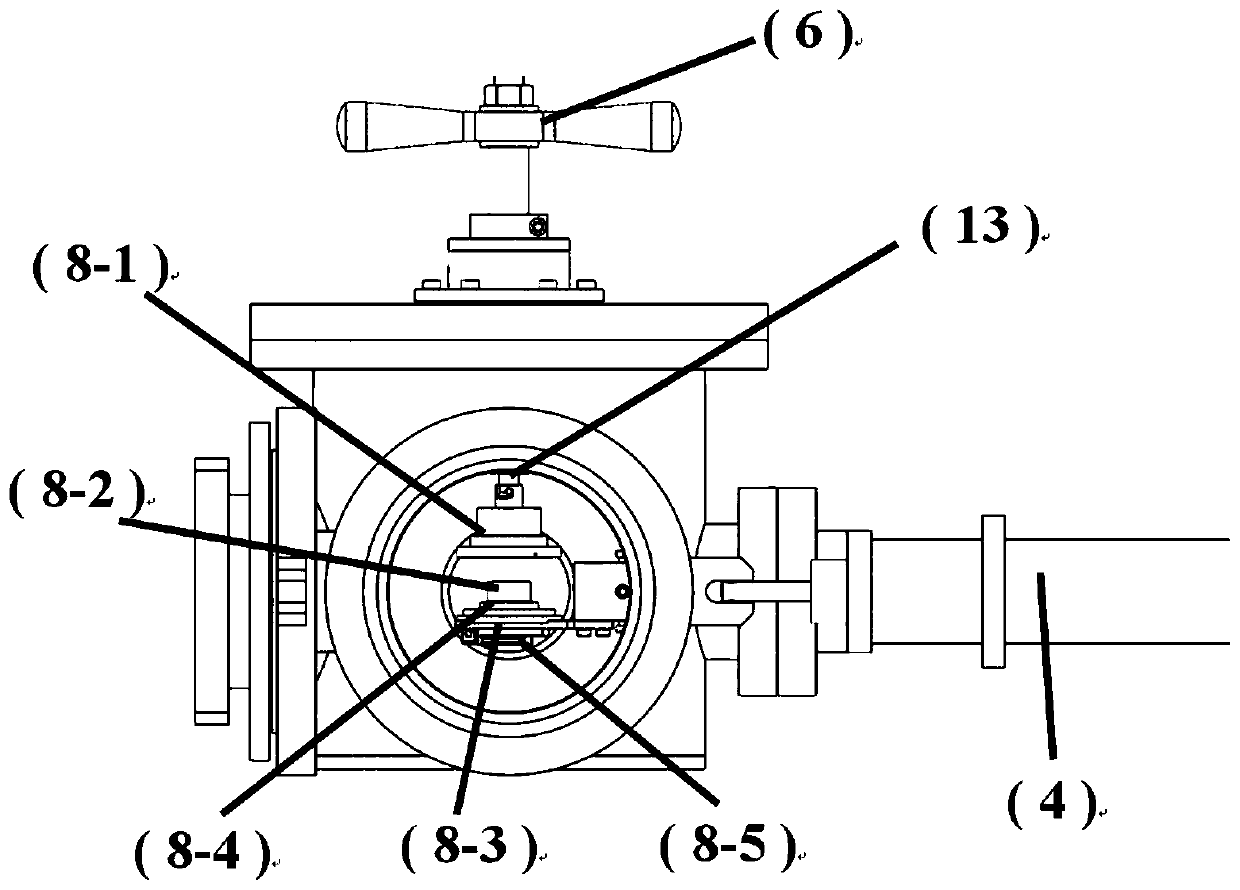

[0029] Such as Figure 1-Figure 2As shown, the sample sealing and vacuum transfer device for the cross-platform connection of electron microscope or micro-nano laser processing system of the present invention mainly includes: a vacuum sample chamber and a vacuum transition chamber for conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com