Desiliconization method of high alumina fly ash

A technology of high-aluminum fly ash and fly ash, which is applied in the field of solid waste resource utilization, can solve problems such as the inability to achieve low-cost desiliconization of fly ash, and achieve the benefits of large-scale production and application, improve desiliconization efficiency, The effect of increasing the Al-Si ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

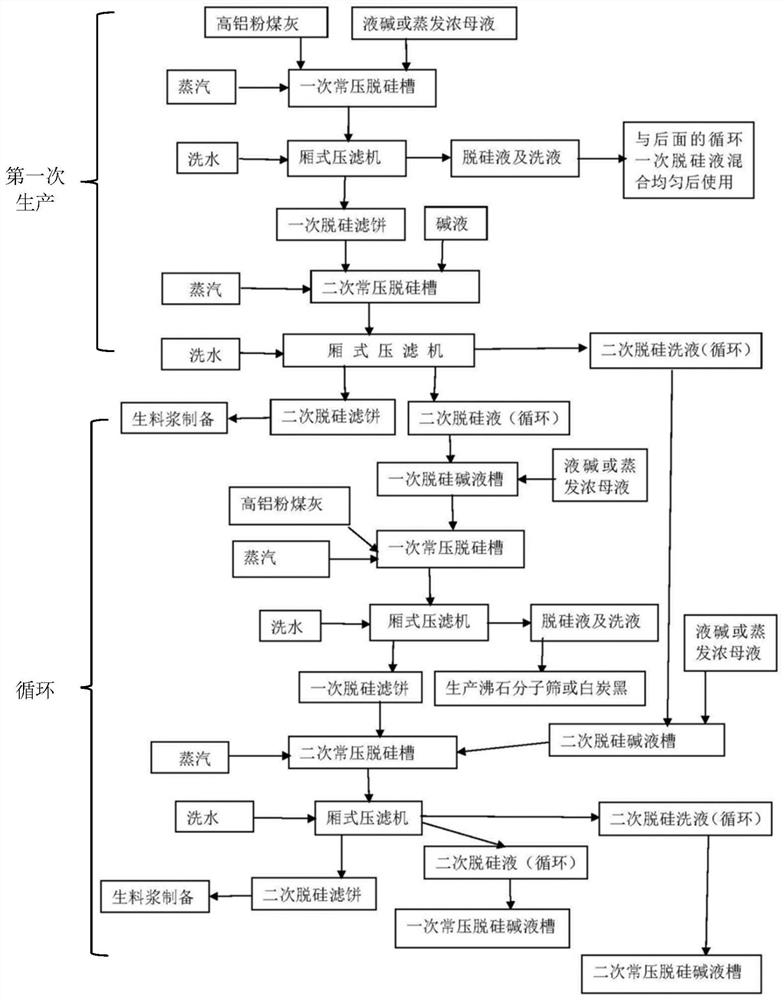

Method used

Image

Examples

Embodiment 1

[0056] This embodiment is a method for desiliconization of high-alumina fly ash, comprising the following steps:

[0057] (1) Mix the fly ash and lye into the pre-blending tank through the belt scale and flow meter according to the solid content of 0.25 (mass ratio of fly ash to lye). The lye index is: 110g / l. After the coal ash is fed, stir for 30 minutes, and check whether the solid content index of the slurry reaches 0.25;

[0058] (2) Pump the blended slurry that meets the index into the pre-desilication tank, open the steam valve to start heating, when the temperature reaches 95°C, close the steam valve, and when the temperature reaches 102°C, close the steam valve, start to keep warm, and keep warm for 1 hour;

[0059] (3) Open the feed valve of the primary desiliconization chamber filter press and the feed valve of the sodium silicate solution tank, close the air compressor and water washing valve; pump the desiliconization slurry that has been kept warm into the primar...

Embodiment 2

[0075] This embodiment is a method for desiliconization of high-alumina fly ash, comprising the following steps:

[0076] (1) Mix the fly ash and lye into the pre-blending tank through the belt scale and flow meter according to the solid content of 0.17 (mass ratio of fly ash to lye), the lye index is: 80g / l, lye and powder After the coal ash is fed, stir for 30 minutes, and check whether the solid content index of the slurry reaches 0.17;

[0077] (2) Pump the blended slurry that meets the index into the pre-desilication tank, open the steam valve to start heating, when the temperature reaches 90°C, close the steam valve, and when the temperature reaches 95°C, close the steam valve, start heat preservation, and keep heat for 1 hour;

[0078] (3)-(9) are the same as embodiment 1;

[0079] (10) When the slurry in the secondary desiliconization tank reaches the corresponding volume, open the coil to raise the temperature. When the temperature reaches 90°C, close the steam valve...

Embodiment 3

[0085] This embodiment is a method for desiliconization of high-alumina fly ash, comprising the following steps:

[0086] (1) Mix the fly ash and lye into the pre-blending tank through the belt scale and flow meter according to the solid content of 0.33 (mass ratio of fly ash to lye). The lye index is: 120g / l. After the coal ash is fed, stir for 30 minutes, and check whether the solid content index of the slurry reaches 0.33;

[0087] (2) Pump the blended slurry that meets the index into the pre-desilication tank, open the steam valve to start heating, when the temperature reaches 100°C, close the steam valve, and when the temperature reaches 105°C, close the steam valve, start to keep warm, and keep warm for 1 hour;

[0088] (3)-(9) are the same as embodiment 1;

[0089] (10) When the slurry in the secondary desiliconization tank reaches the corresponding volume, open the coil to raise the temperature. When the temperature reaches 100°C, close the steam valve. When the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com