Desilication agent for molten iron pretreatment and preparation method thereof

A technology of hot metal pretreatment and desiliconization agent, which is applied in the field of iron and steel metallurgy, can solve the problems of low desiliconization efficiency, unfavorable removal of sulfur and phosphorus, uneven composition, etc., and achieve good desiliconization dynamic conditions, uniform and stable product composition, The effect of chemical composition stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

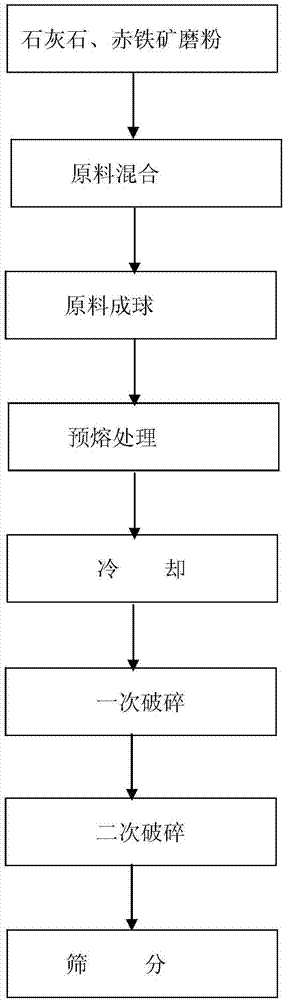

[0077] A preparation method for a desiliconization agent for molten iron pretreatment, comprising the following steps:

[0078] (1) Limestone milling, the limestone is ground to a fine powder of 0-1 mm by a mill;

[0079] (2) Hematite grinding, the hematite is ground to a fine powder of 0-1 mm by a mill;

[0080] (3) raw materials are mixed, and hematite powder, limestone powder, soda ash are mixed in specific proportions, preferably, its mixed percentage by weight: 60 parts of hematite, 30 parts of limestone, 10 parts of soda ash;

[0081] (4) Raw material molding, the raw material mixed in step (3) is pressed and formed by a ball press, and the formed one is ellipsoidal, and the diameter of the ellipsoid is 5-50mm;

[0082] (5) Add the ellipsoidal raw material in step (4) into the pre-melting furnace, and then heat it with natural gas in the pre-melting furnace burner. The melting temperature is 1400° C. to melt the ellipsoidal raw material. 7 hours; form a liquid desilico...

Embodiment 2

[0088] A preparation method for a desiliconization agent for molten iron pretreatment, comprising the following steps:

[0089] (1) Limestone milling, the limestone is ground to a fine powder of 0-1 mm by a mill;

[0090] (2) Hematite grinding, the hematite is ground to a fine powder of 0-1 mm by a mill;

[0091] (3) raw materials are mixed, the hematite powder, limestone powder, soda ash that step (1) and step (2) are ground are mixed, and its mixed percentage by weight: 65 parts of hematite, 25 parts of limestones, 10 parts of soda ash ;

[0092] (4) Raw material molding, the raw material mixed in step (3) is pressed and formed by a ball press, and the formed one is ellipsoidal, and the diameter of the ellipsoid is 5 to 50 mm;

[0093] (5) Pre-melting treatment, add the ellipsoidal raw material in step (4) into the pre-melting furnace, and then heat it with natural gas in the pre-melting furnace burner, the melting temperature is 1400 ° C, melt the ellipsoidal raw material...

Embodiment 3

[0099] A preparation method for a desiliconization agent for molten iron pretreatment, comprising the following steps:

[0100] (1) Limestone milling, the limestone is ground to a fine powder of 0-1 mm by a mill;

[0101] (2) Hematite grinding, the hematite is ground to a fine powder of 0-1 mm by a mill;

[0102] (3) the hematite powder, limestone powder, soda ash that step (1) and step (2) grind are mixed, and its mixed percentage by weight: 70 parts of hematite, 20 parts of limestones, 10 parts of soda ash;

[0103] (4) Raw material molding, the raw material mixed in step (3) is pressed and formed by a ball press, and the formed one is ellipsoidal, and the diameter of the ellipsoid is 5 to 50 mm;

[0104] (5) Pre-melting treatment, adding the ellipsoidal raw material in step (4) into the pre-melting furnace, and then heating it with natural gas in the pre-melting furnace burner, the melting temperature is 1460 ° C, melting the ellipsoidal raw material, and heating continues...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com