Fiber unwinding machine and unwinding mode

An unwinding machine and fiber technology, applied in fiber processing, textile and papermaking, rayon filament physical therapy, etc., can solve the problems of not being able to become a smooth and smooth tow, reducing the quality of the tow, and increasing the heat treatment efficiency. , The effect of reducing the spiral state of the tow and shortening the heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

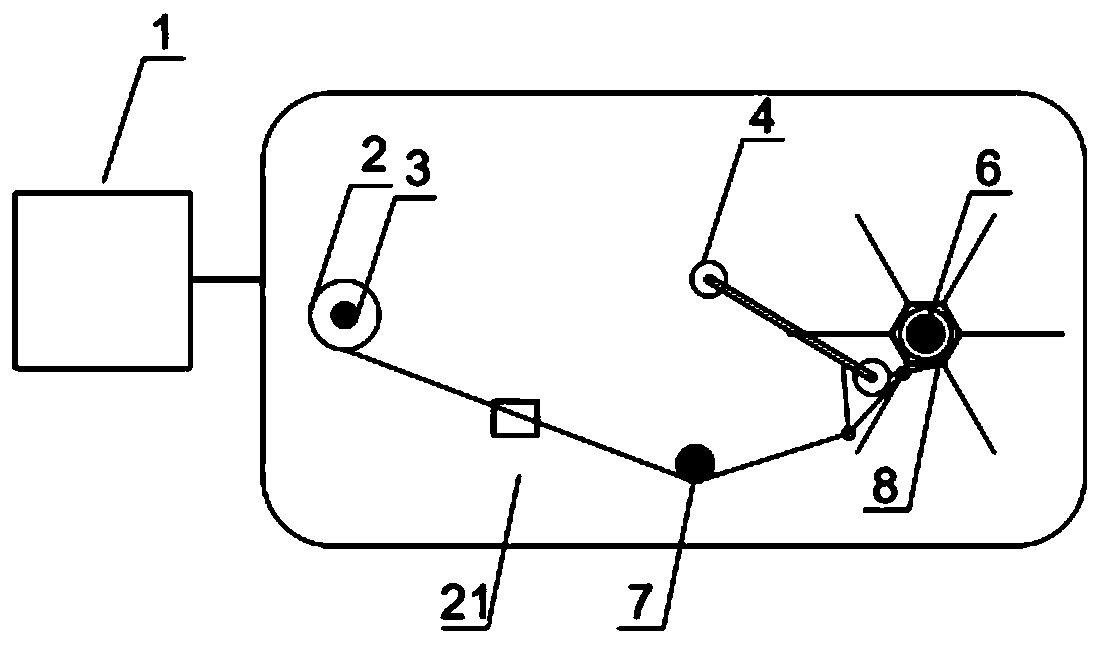

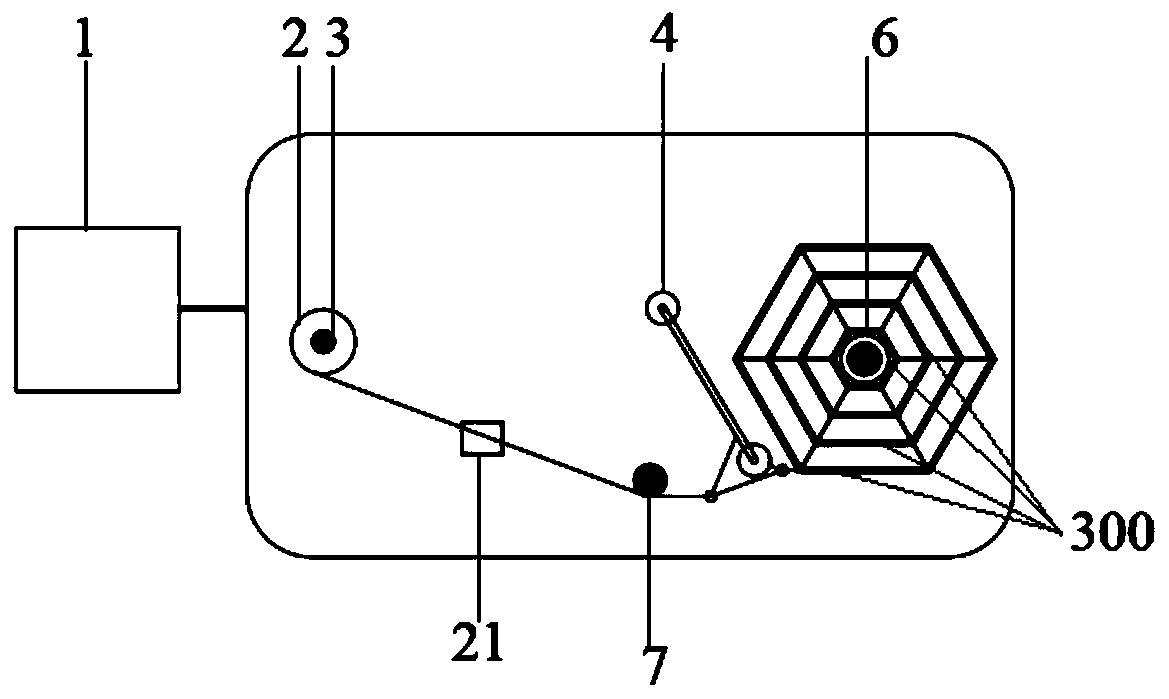

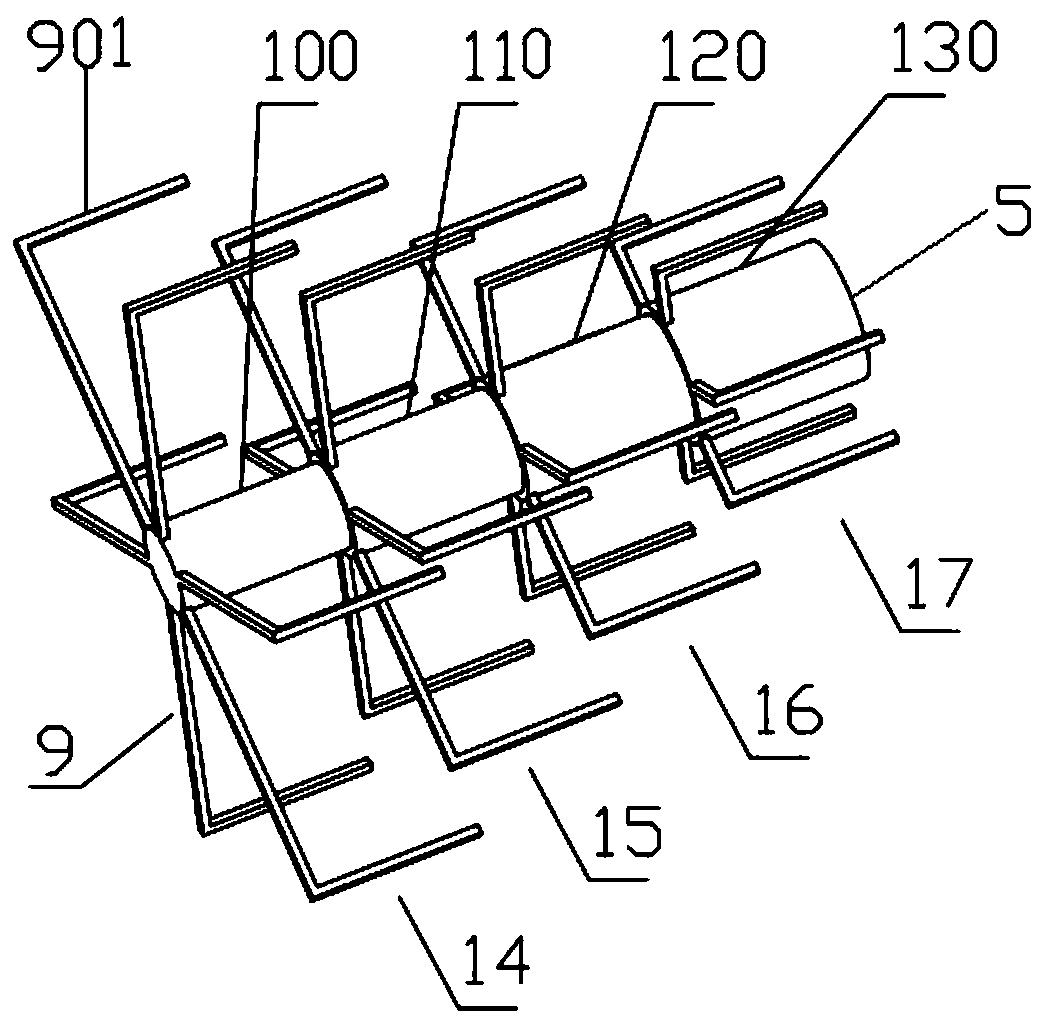

[0043] This embodiment provides a new type of unwinding machine, which is used in the production process of polyarylate fibers in this embodiment. The unwinding machine includes an unwinding mechanism, a winding head clamp 6 and a The bobbin 5 on the clip 6, the bobbin 5 includes a telescopic central shaft 8, the central shaft 8 includes at least two central sleeves that are nested, and each of the central sleeves is provided with a A group of outer rings, the outer rings are used to wind the tow unwound by the unwinding mechanism, and the outer rings of the different central sleeves are sleeved; the central shaft is detachably connected to the winding On the head clamp, after the central shaft is opened, the outer ring on the center sleeve close to the winding head clamp is sleeved inside, and the outer ring of the center sleeve away from the winding head clamp is sleeved outside ; A hole-shaped heat dissipation space is formed on the outer ring.

[0044] The sleeved outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com