Range hood controlling method making impeller free of manual maintenance

A technology of a range hood and a control method, which is applied in the directions of pump control, oil fume removal, components of a pumping device for elastic fluid, etc. It can solve the problem of regular cleaning of the impeller, prevent corrosion, and improve the aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

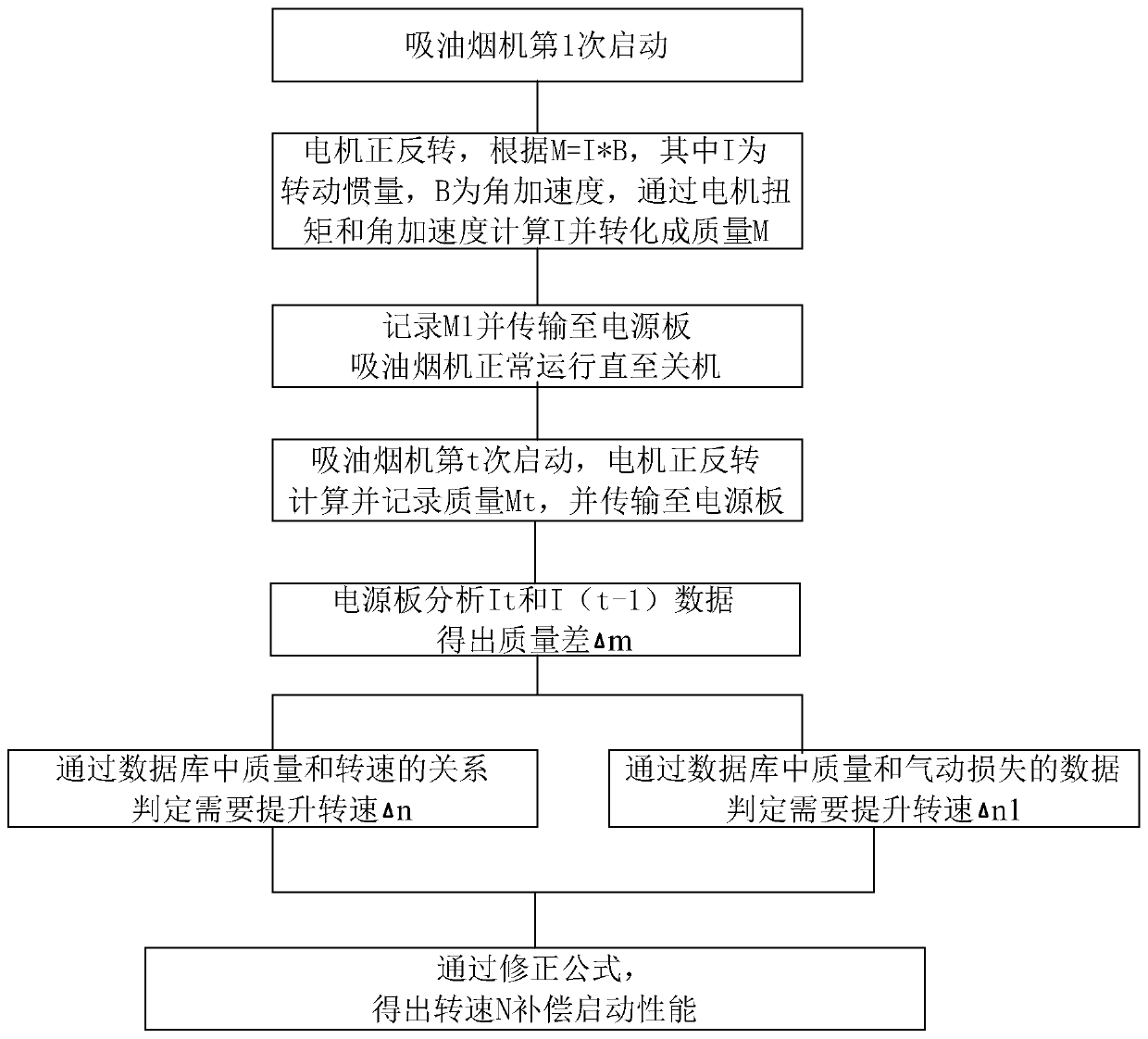

[0024] see figure 1 , a method for controlling a range hood without manual maintenance of an impeller, comprising the following steps:

[0025] 1) Start the range hood for the first time;

[0026] 2) The motor of the fan of the range hood rotates forward or reversely, according to M=I*B, wherein I is the moment of inertia, B is the angular acceleration, M is the mass of the impeller, and I is calculated by the motor torque T and the angular acceleration B (by Moment of inertia theorem, torque T=IB, torque and angular acceleration can be detected by torque sensor and encoder) and converted into M, and the moment of inertia I is recorded at the first start 1 and the impeller mass M 1 And transmit to the power board of the range hood, the range hood runs normally until it is shut down;

[0027] 3) When the range hood is started for the tth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com