Conductive slip ring for lightning protection

A conductive slip ring and lightning protection technology, which is applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of inability to realize lightning protection for rotating equipment, low instantaneous large current carrying capacity, and low contact reliability, and achieve lightning protection ability, realize the lightning protection function, and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

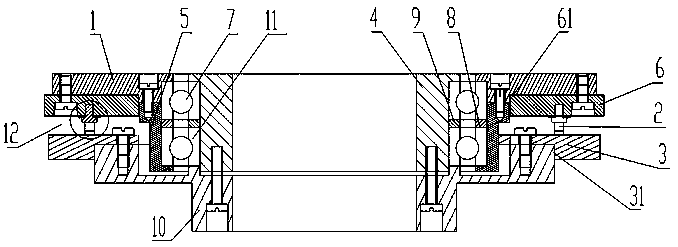

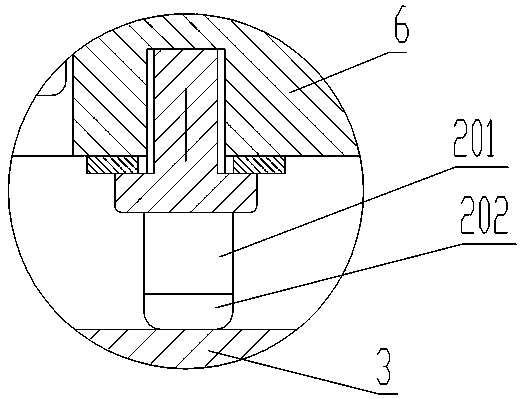

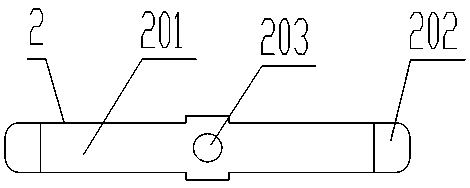

[0023] A conductive slip ring for lightning protection, comprising a fixed plate 6, a moving plate 3, a stator connecting plate 1, a bearing seat 5, a central shaft 4, a rotor connecting plate 10, a reed set 2, an upper bearing 7 and a lower bearing 11, in The bottom of the ring-shaped stator connecting plate 1 is provided with a fixed plate step groove 61, through the cooperation and positioning of the fixed plate step groove 61, the screw fixes the ring-shaped fixed plate 6 on the bottom of the stator connecting plate 1; The step groove 31 of the moving disk, through the cooperative positioning of the step groove 31 of the moving disk, the screw fixes the moving disk 3 on the top of the ring-shaped rotor connecting disk 10; the fixed disk 1 is opposite to the moving disk 3 and there is a gap 12; the ring-shaped central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com