Hull outer plate curved surface forming equipment based on double mechanical arms and implementation method thereof

A hull plate and curved surface forming technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing labor intensity, unable to realize simultaneous heating of ship plates, and general heating effect, so as to improve work efficiency and high Transmission reversibility, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

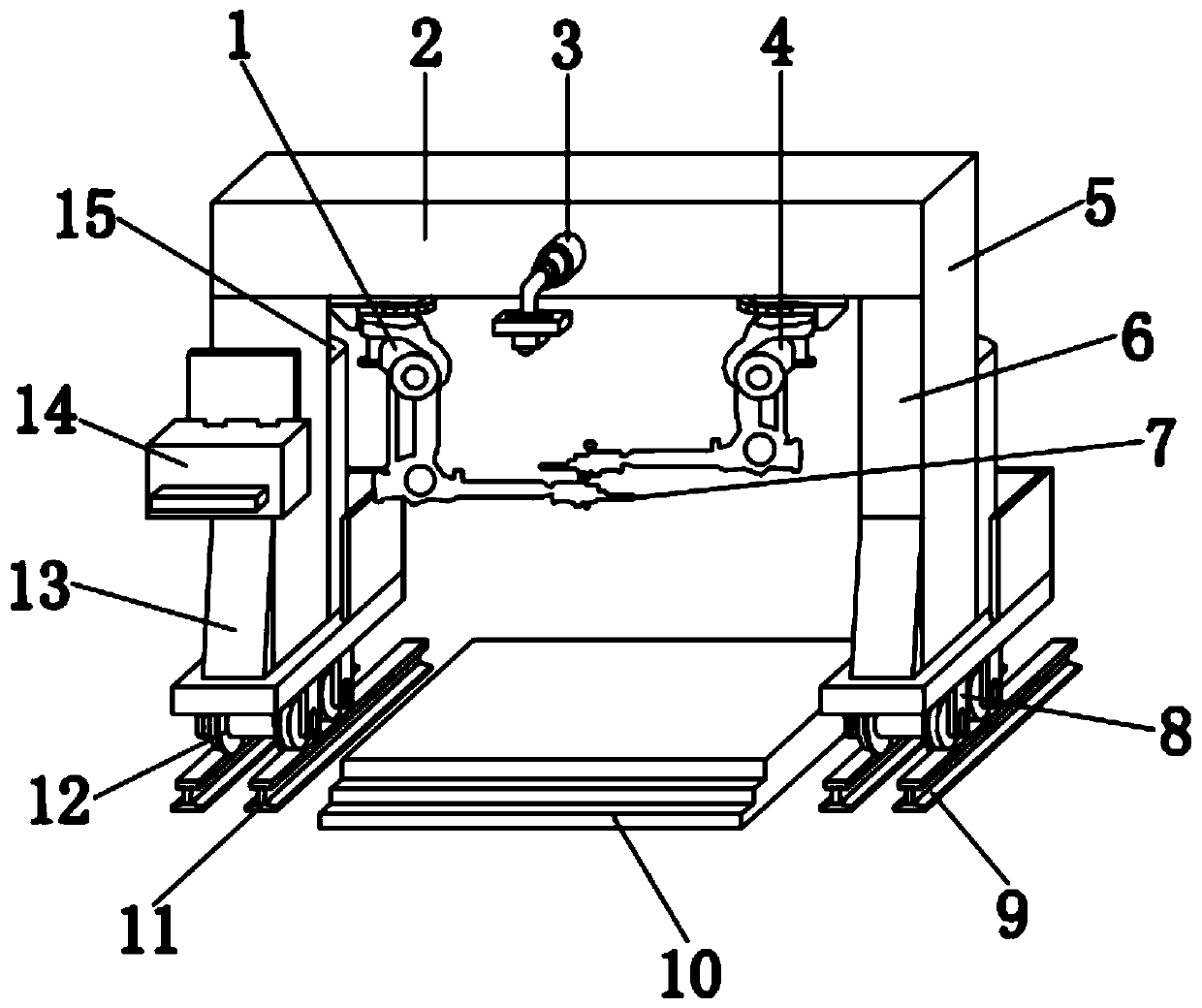

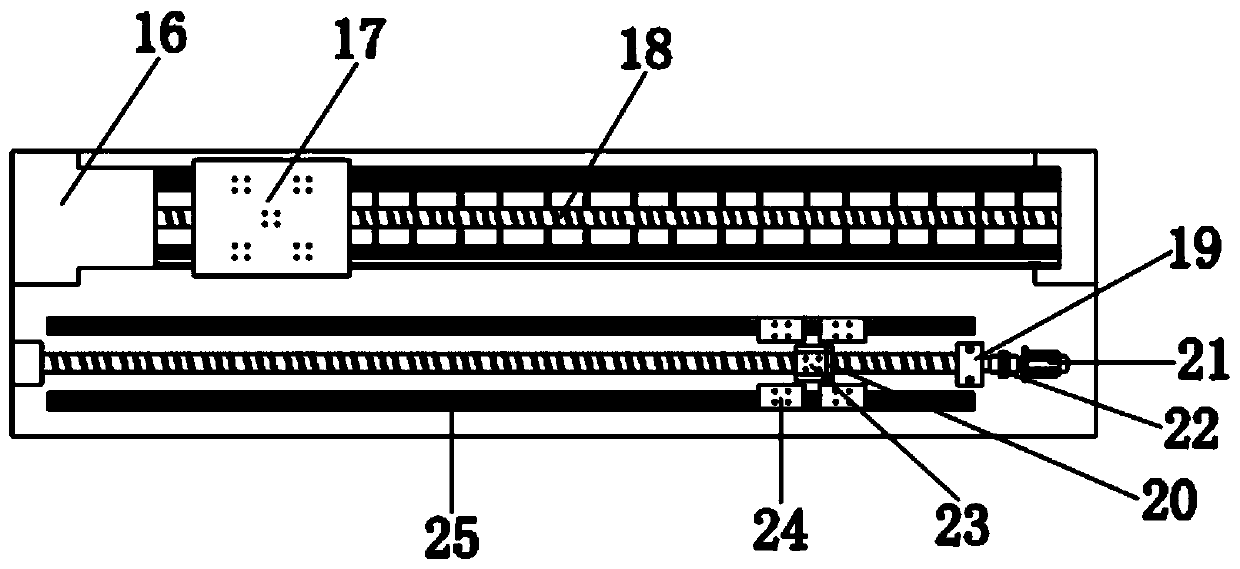

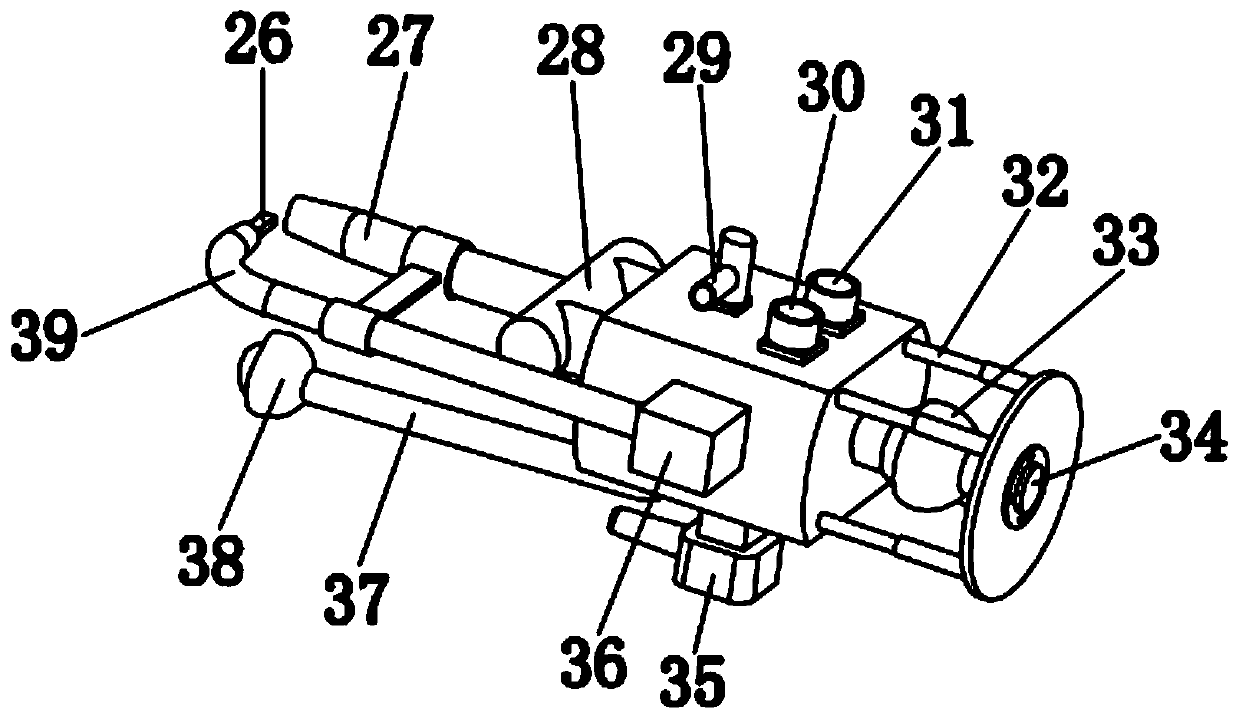

[0038] like figure 1 As shown, the gantry-type dual-arm hull hull surface forming machine of the present invention includes a main body which is a gantry 6, on which the execution device No. Industrial camera 3, motion device servo motor 13, floor guide rails 9, 11, and a numerical control device console 14 is installed under the left side of the gantry frame. This console provides real-time display functions and input command functions for the touchable all-in-one machine to realize molding process control;

[0039] like figure 1 As shown, there is a parts workbench under the gantry;

[0040] like figure 1 As shown, the inside of the gantry 6 is supported by a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com