Resistance reducing agent for slickwater, and preparation method thereof

A drag-reducing agent and slick water technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increased transportation costs and storage costs, inconvenient continuous mixing, and reduced drag-reducing effect, reaching a good market Prospects for application and promotion, reduction of on-site preparation workload, and good drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

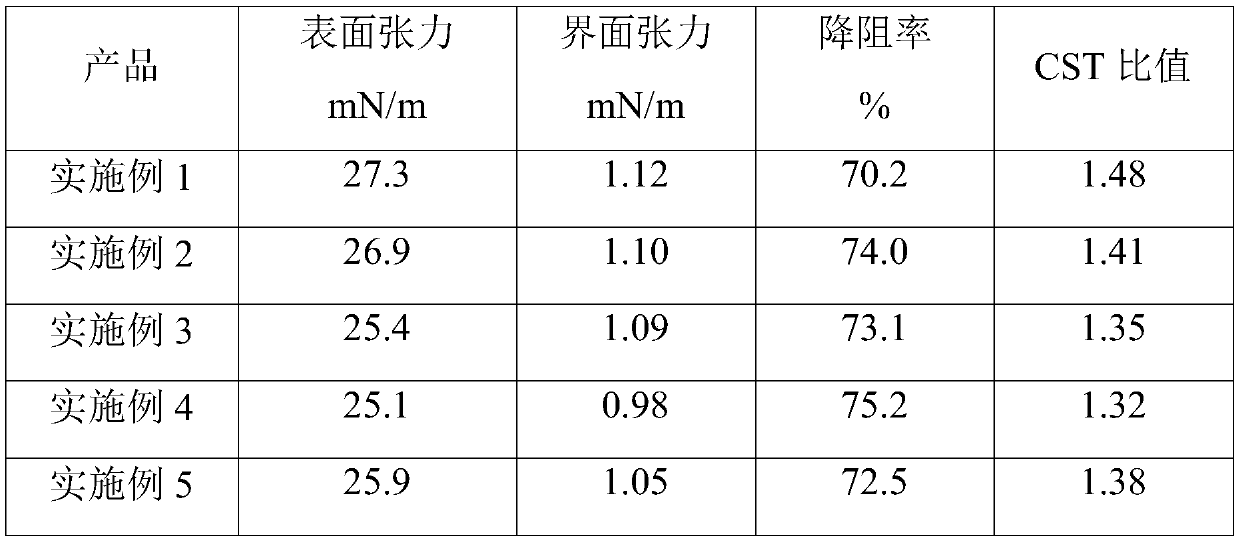

Examples

Embodiment 1

[0016] A preparation method of a drag reducing agent for slippery water, the preparation steps are as follows:

[0017] S1. Mix 20 parts by weight of acrylamide, 5 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, 5 parts by weight of dimethyl hexadecyl allyl ammonium chloride and 100 parts by weight of water, Form an aqueous phase reaction solution;

[0018] S2, 5 parts by weight of perfluorobutyl ethylene, 3 parts by weight of emulsifier and 40 parts by weight of white oil are mixed uniformly to form an oil phase reaction liquid; wherein, the emulsifier is a mixture of TW60 and TX-4, and the weight ratio of the two is 1:0.8;

[0019] S3. After mixing the oil phase reaction liquid and the water phase reaction liquid evenly, under the condition of stirring, pass nitrogen gas to deoxygenate, then raise the temperature to 40°C, add the water phase initiator and the oil phase initiator dropwise, and continue the reaction for 3 hours to obtain the drag reducing agent ...

Embodiment 2

[0021] A preparation method of a drag reducing agent for slippery water, the preparation steps are as follows:

[0022] S1. Mix 25 parts by weight of acrylamide, 5 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, 8 parts by weight of dimethyl hexadecyl allyl ammonium chloride and 100 parts by weight of water, Form an aqueous phase reaction solution;

[0023] S2, 10 parts by weight of perfluorobutyl ethylene, 5 parts by weight of emulsifier and 40 parts by weight of white oil are mixed uniformly to form an oil phase reaction liquid; wherein, the emulsifier is a mixture of TW60 and TX-4, and the weight ratio of the two is 1:1;

[0024] S3. After mixing the oil phase reaction liquid and the water phase reaction liquid evenly, under the condition of stirring, pass nitrogen gas to deoxygenate, then raise the temperature to 50°C, add the water phase initiator and the oil phase initiator dropwise, and continue the reaction for 4 hours to obtain the drag reducing agent ...

Embodiment 3

[0026] A preparation method of a drag reducing agent for slippery water, the preparation steps are as follows:

[0027] S1. Mix 25 parts by weight of acrylamide, 10 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, 10 parts by weight of dimethyl hexadecyl allyl ammonium chloride and 100 parts by weight of water, Form an aqueous phase reaction solution;

[0028] S2, 10 parts by weight of perfluorobutyl ethylene, 4 parts by weight of emulsifier and 40 parts by weight of white oil are uniformly mixed to form an oil phase reaction liquid; wherein, the emulsifier is a mixture of TW60 and TX-4, and the weight ratio of the two is 1:1.2;

[0029] S3. After mixing the oil phase reaction solution and the water phase reaction solution evenly, under the condition of stirring, pass nitrogen gas to remove oxygen, then raise the temperature to 60°C, add the water phase initiator and the oil phase initiator dropwise, and continue the reaction for 5 hours to obtain the drag reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com