Titanium alloy surface inflaming retarding sealing integrated coating and preparing method an application thereof

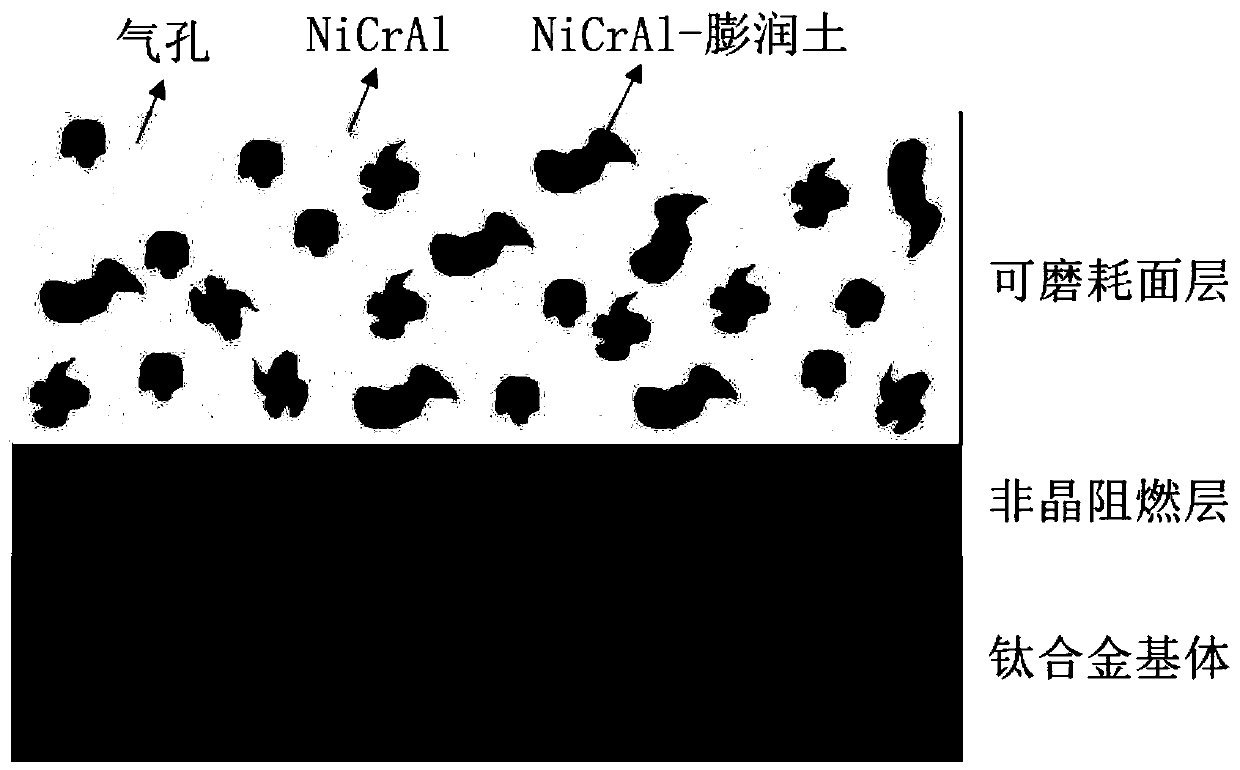

A sealing coating and titanium alloy technology, applied in metal material coating process, coating, fusion spraying, etc., can solve problems such as increased fuel consumption and reduced engine efficiency, and achieve reduced maintenance costs and simplified structure , the effect of low density structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Surface treatment of titanium alloy substrates: TC4 titanium alloy samples with a diameter of 25 mm and a thickness of about 3.5 mm are used as disc samples. Grind to 800 mesh step by step, so that the sample exposes a flat and relatively smooth sprayed surface;

[0026] The substrate is sandblasted by a sandblasting machine. The sand composition used for sandblasting is alumina, and the particle size of the sand is 30 meshes, so that the substrate can obtain a certain roughness and improve the bonding force between the coating and the substrate. After sandblasting The base roughness Ra is 1.5μm;

[0027] (2) Preheating of the titanium alloy base material: preheating the titanium alloy with a supersonic flame to make the base material expand properly, the preheating temperature is 100°C-130°C, and the preheating time is 20S;

[0028] (3) Preparation of flame retardant layer coating: the spraying material of flame retardant layer coating is Ti 40 Zr 25 Ni 3 Cu 1...

Embodiment 2

[0032] (1) Surface treatment of titanium alloy substrates: TC4 titanium alloy samples with a diameter of 25 mm and a thickness of about 3.5 mm are used as disc samples. Grind to 800 mesh step by step, so that the sample exposes a flat and relatively smooth sprayed surface;

[0033] The substrate is sandblasted by a sandblasting machine. The sand composition used for sandblasting is alumina, and the particle size of the sand is 30 meshes, so that the substrate can obtain a certain roughness and improve the bonding force between the coating and the substrate. After sandblasting The base roughness Ra is 1.5μm;

[0034] (2) Preheating of the titanium alloy base material: the titanium alloy is preheated with a supersonic flame to cause proper expansion of the base material. The preheating temperature is 100°C-130°C; the preheating time is 20S.

[0035] (3) Preparation of flame retardant layer coating: the spraying material of flame retardant layer coating is Ti 40 Zr 25 Ni 3 Cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com