Low-pressure gas supply system capable of realizing high-efficiency utilization of cold energy of LNG fuel

A technology of gas supply system and cold energy, applied in the direction of charging system, application, oil supply device, etc., can solve the problem of consuming large boiler steam, etc., achieve good safety and applicability, improve safety, and flexible heat source collection scheme Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

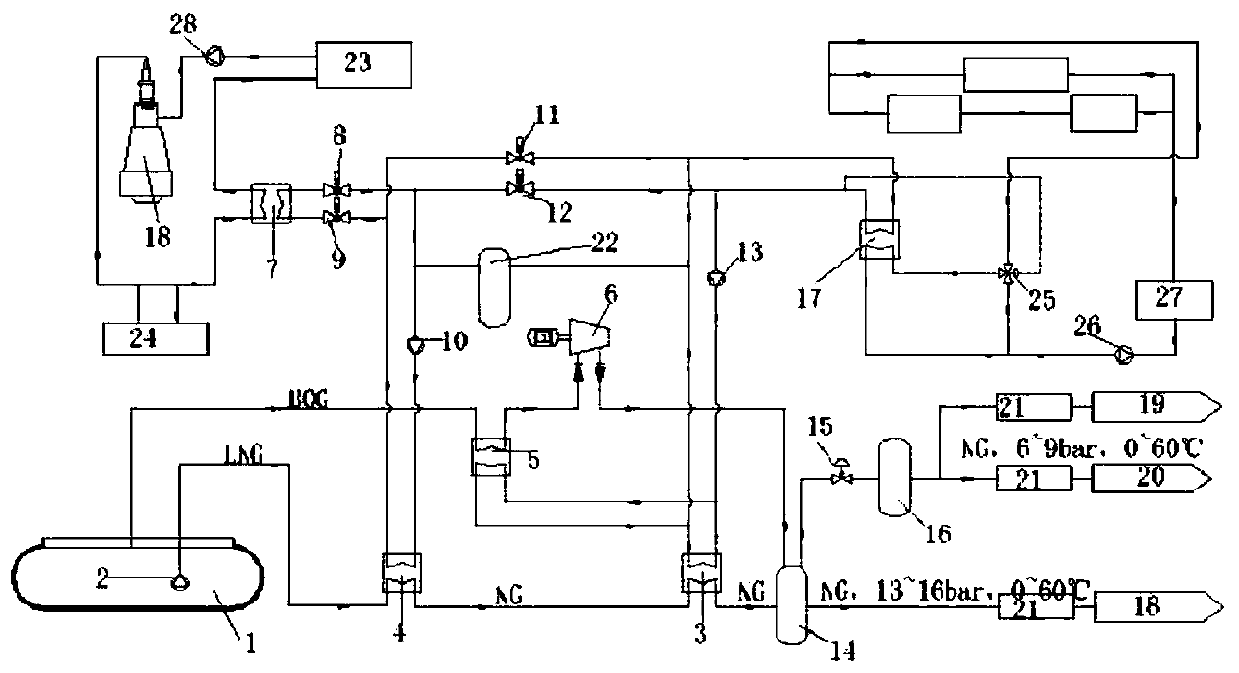

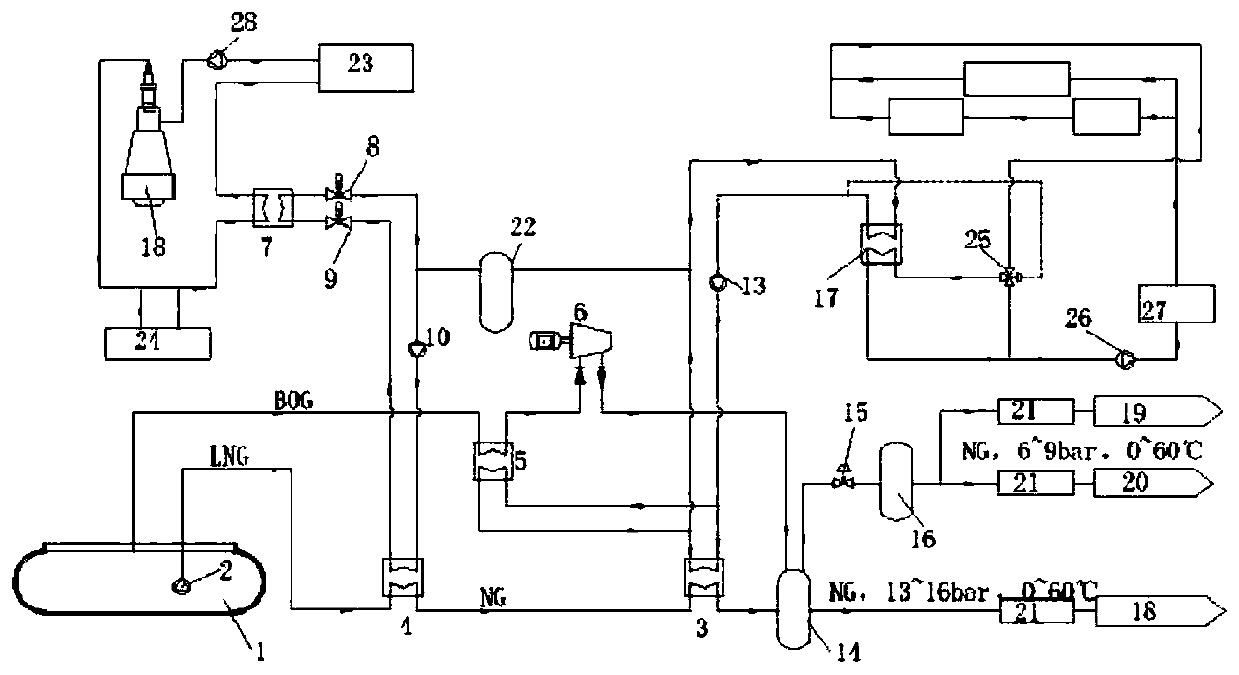

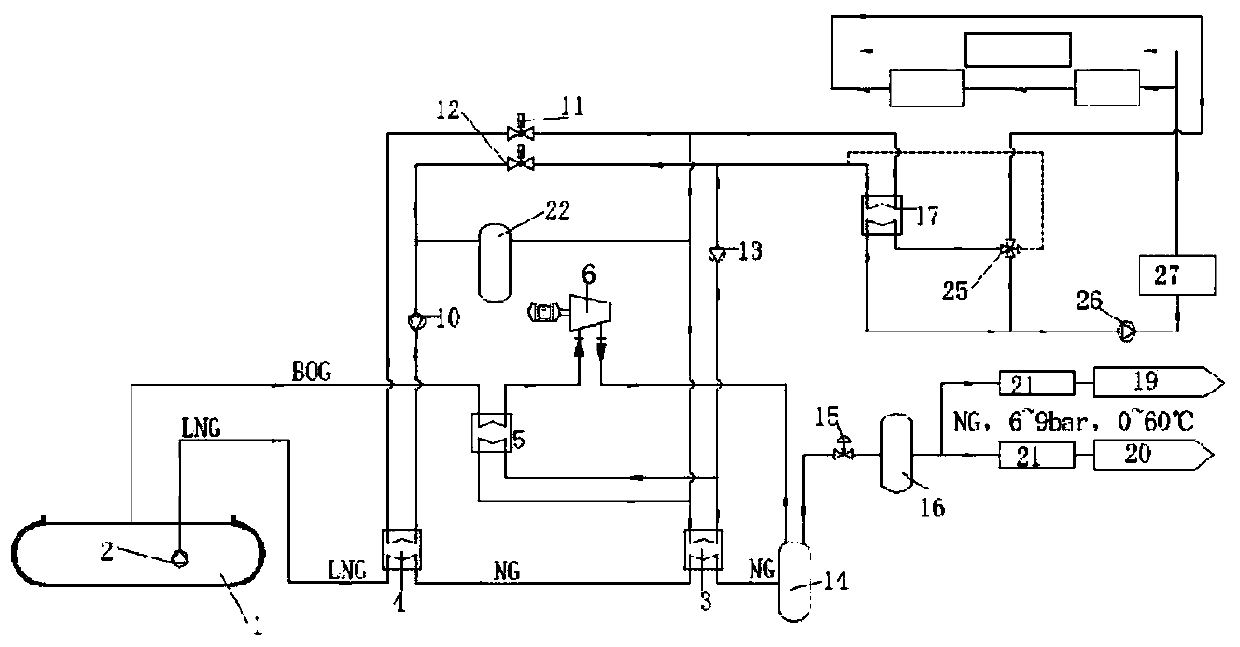

[0035] The present invention will be further described in conjunction with accompanying drawing, as figure 1 A low-pressure gas supply system for efficient utilization of cold energy of LNG fuel is shown, including a central fresh water circulation system and a high-temperature jacket water circulation system. The LNG storage tank 1 is equipped with an LNG low-pressure pump 2, and the LNG low-pressure pump passes through the pipeline and the LNG evaporator 4-phase connection, LNG evaporator, LNG heater 3, and host gas buffer tank 14 are connected in series through pipelines. The LNG storage tank is connected to the BOG pre-heater 5 through pipelines, and the BOG pre-heater, BOG compressor 6 and host gas buffer tank are connected in series through pipelines.

[0036] The LNG evaporator is connected to the water glycol jacket water heat exchanger 7 through pipes and valves to form the first circulation network, and the water glycol jacket water heat exchanger is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com