ZIF-8-derived hollow Fe/Cu-N-C type oxygen reduction catalyst and preparation method and application thereof

A technology of ZIF-8 and catalyst, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost of Pt/C catalyst, easy poisoning of methanol, low stability, etc., and achieve low production cost, easy industrialization, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

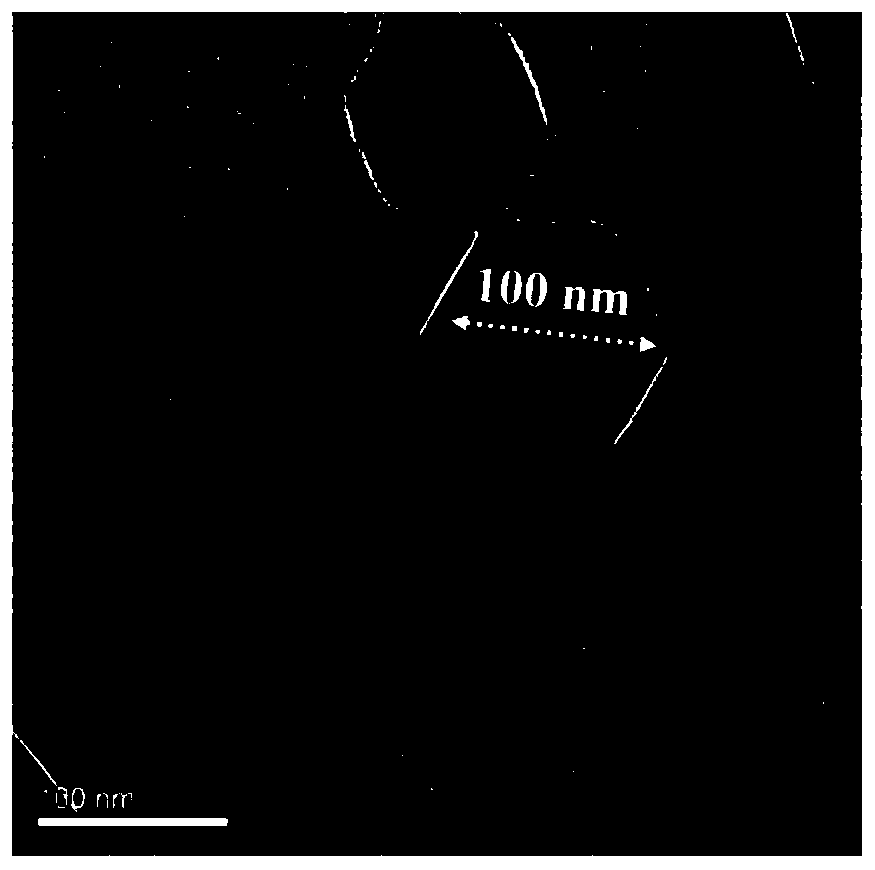

[0040] Synthesis of precursor 100nm size ZIF-8:

[0041] Weigh 0.84 g of zinc nitrate hexahydrate, dissolve it in 100 mL of methanol solution, and dissolve it completely by ultrasound to obtain a methanol solution of zinc nitrate hexahydrate; then take 1.61 g of 2-methylimidazole and dissolve in 100 mL of methanol solution In the process, ultrasonication is used to completely dissolve it to obtain a methanol solution of 2-methylimidazole; the two solutions obtained above are mixed and stirred at room temperature for 24 hours to obtain a white precipitate. Centrifuge the white precipitate and add it to 50mL methanol solution, reflux for 12h at 80°C, the obtained methanol solution of ZIF-8 is centrifuged and washed with methanol three times, and then dried under vacuum overnight at 60°C to obtain white solid powder ZIF-8 . The obtained white solid powder ZIF-8 was ground and vacuum activated at 200° C. for 2 h to obtain pure ZIF-8 with a size of 100 nm.

[0042] figure 1 This is a ...

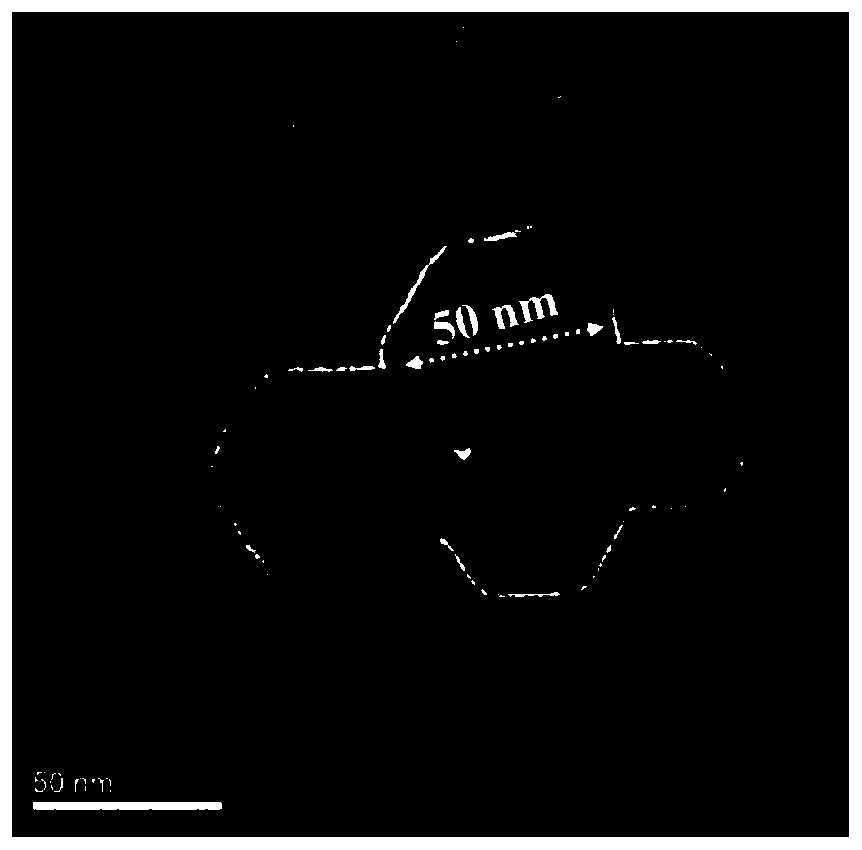

Embodiment 2

[0044] Weigh 0.84 g of zinc nitrate hexahydrate, dissolve it in 50 mL of methanol solution, and dissolve it completely by ultrasound to obtain a methanol solution of zinc nitrate hexahydrate; then take 1.61 g of 2-methylimidazole and dissolve in 50 mL of methanol solution In the process, ultrasonication is used to completely dissolve it to obtain a methanol solution of 2-methylimidazole; the two solutions obtained above are mixed and stirred at room temperature for 12 hours to obtain a white precipitate. Centrifuge the white precipitate and add it to 100mL methanol solution, reflux at 80℃ for 12h, the obtained ZIF-8 methanol solution was centrifuged and washed with methanol three times, then dried under vacuum overnight at 60℃ to obtain white solid powder ZIF-8 . The obtained white solid powder ZIF-8 was ground and vacuum activated at 200°C for 2 hours to obtain a small amount of pure ZIF-8 with a size of 50 nm.

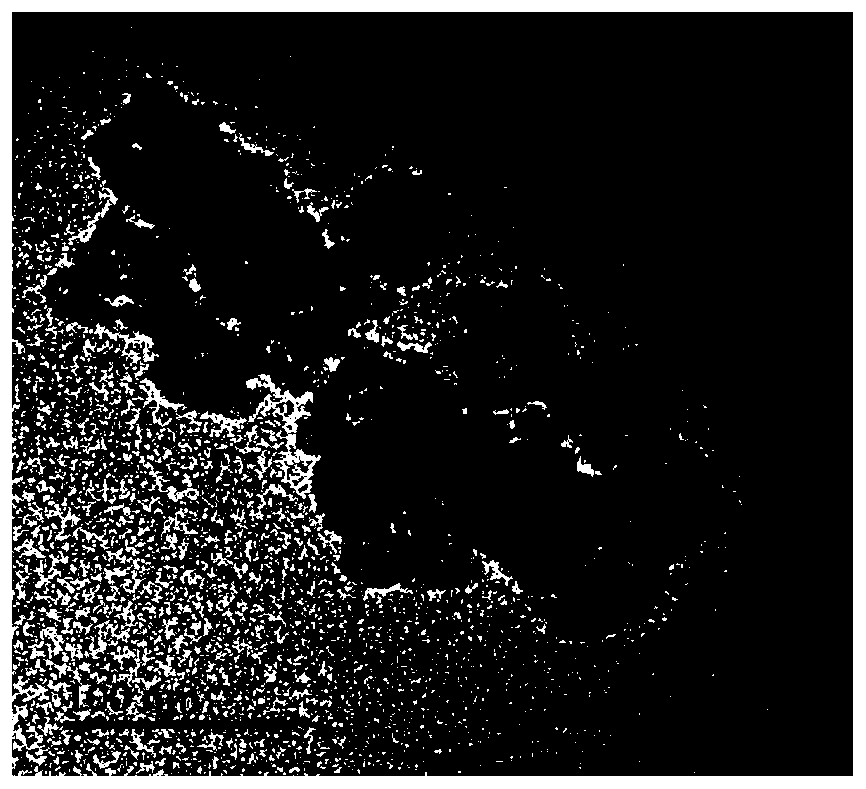

Embodiment 3

[0046] A ZIF-8-derived hollow Fe / Cu-N-C oxygen reduction catalyst, the specific preparation method is as follows:

[0047] Step 1. Preparation of precursor ZIF-8 material:

[0048] Weigh 0.84 g of zinc nitrate hexahydrate, dissolve it in 50 mL of methanol solution, and dissolve it completely by ultrasound to obtain a methanol solution of zinc nitrate hexahydrate; then take 1.61 g of 2-methylimidazole and dissolve in 50 mL of methanol solution In the process, ultrasound was used to completely dissolve it to obtain a methanol solution of 2-methylimidazole; the two solutions obtained above were mixed and stirred at room temperature for 24 hours to obtain a white precipitate. Centrifuge the white precipitate and add it to 100mL methanol solution, reflux at 80℃ for 12h, the obtained ZIF-8 methanol solution was centrifuged and washed with methanol three times, then dried under vacuum overnight at 60℃ to obtain white solid powder ZIF-8 . The obtained white solid powder ZIF-8 was ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com