Preparation method of dendrobium aurantiacum powder

A technology for stacking dendrobium and dendrobium tablets, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, powder delivery, etc. Strong inhibitory effect, improving extraction rate and gypsum rate, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

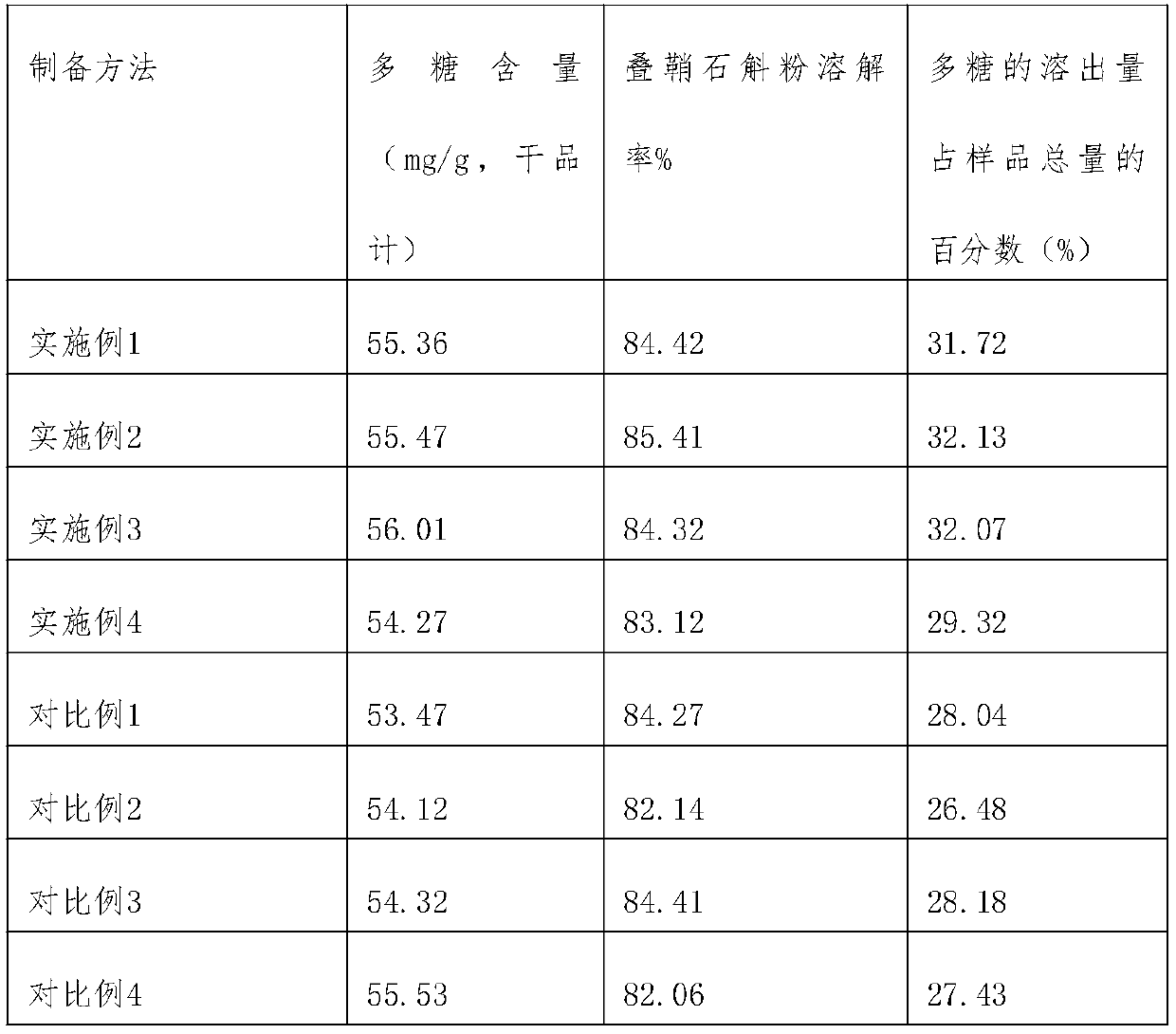

Examples

Embodiment 1

[0027] A preparation method of dendrobium sheath powder, comprising the following steps:

[0028] (1) Cleaning treatment: Remove the leaves of fresh Dendrobium sheathing, put them in the cleaning solution and soak them for 6 minutes, then take them out and send them to the dehydrator to remove the moisture on the surface, and set aside:

[0029] (2) Drying: send the dehydrated Dendrobium sheaths to a hot air circulation oven, dry at 50-60°C until the water content is 60-70%, and then cut into dendrobium slices;

[0030] (3) freezing treatment: freezing the dendrobium sheet at -15°C for 20h;

[0031] (4) differential pressure puffing treatment: adding the frozen dendrobium slices into the puffing tank and carrying out pressure differential puffing to obtain puffed dendrobium slices;

[0032] (5) Low-temperature reflux extraction and concentration: add the expanded Dendrobium flakes to a hot reflux low-temperature extraction low-temperature concentrator, add an organic solvent ...

Embodiment 2

[0042] A preparation method of dendrobium sheath powder, comprising the following steps:

[0043] (1) Cleaning treatment: remove the leaves of fresh Dendrobium sheathing, put them in the cleaning solution and soak them for 8 minutes, then take them out and send them to the dehydrator to remove the moisture on the surface, and set aside:

[0044](2) Drying: send the dehydrated Dendrobium sheaths to a hot air circulation oven, dry at 50-60°C until the water content is 60-70%, and then cut into dendrobium slices;

[0045] (3) freezing treatment: freezing the dendrobium sheet at -18°C for 15h;

[0046] (4) differential pressure puffing treatment: adding the frozen dendrobium slices into the puffing tank and carrying out pressure differential puffing to obtain puffed dendrobium slices;

[0047] (5) Low-temperature reflux extraction and concentration: add the expanded Dendrobium flakes to a heat reflux low-temperature extraction low-temperature concentrator, add an organic solvent ...

Embodiment 3

[0057] A preparation method of dendrobium sheath powder, comprising the following steps:

[0058] (1) Cleaning treatment: Remove the leaves of fresh Dendrobium sheathing, put them in the cleaning solution and soak them for 8 minutes, then take them out and send them to the dehydrator to remove the moisture on the surface, and set aside:

[0059] (2) Drying: send the dehydrated Dendrobium sheaths to a hot air circulation oven, dry at 50-60°C until the water content is 60-70%, and then cut into dendrobium slices;

[0060] (3) freezing treatment: freezing the dendrobium sheet at -18°C for 20h;

[0061] (4) differential pressure puffing treatment: adding the frozen dendrobium slices into the puffing tank and carrying out pressure differential puffing to obtain puffed dendrobium slices;

[0062] (5) Low-temperature reflux extraction and concentration: add the expanded Dendrobium flakes to a heat reflux low-temperature extraction low-temperature concentrator, add an organic solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com