Preparation method of tin dioxide micron sheet with hexagonal profile

A technology of tin dioxide and micron flakes, applied in tin oxide and other directions, can solve the problem of no tin dioxide micron flakes, etc., and achieve the effects of low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.6 g of dioctyltin oxide, 0.1 g of graphene, and 0.2 g of sublimed sulfur according to the mass ratio of 6:1:2. After the three substances are fully mixed for 10 minutes, press the mixture into several pieces with a thickness of 1 mm and a diameter of 1 cm. The discs were then placed in a crucible and calcined in a muffle furnace at 480° C. for 2 hours to obtain tin dioxide microflakes with hexagonal morphology.

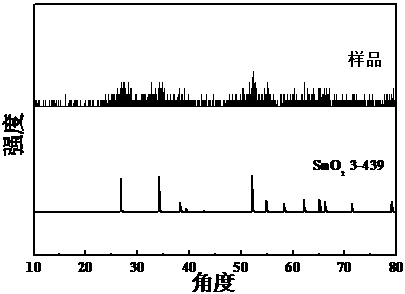

[0017] See figure 1 , figure 1 The positions and intensities of the main diffraction peaks are in good agreement with the standard card of tin dioxide, indicating that the main component of the product is tin dioxide.

[0018] See figure 2 ,from figure 2 It can be seen from the photo that the prepared sample is composed of flake particles with hexagonal morphology, the surface of each flake is very smooth, and each flake can exist independently or interlaced with each other. The length of each piece is about 1 μm, the width is about 0.6 μm, and th...

Embodiment 2

[0020] Weigh 0.7 g of dibutyltin diacetate, 0.1 g of graphene, and 0.2 g of sublimed sulfur according to the mass ratio of 7:1:2. After the three substances are fully mixed for 10 minutes, press the mixture into several pieces with a thickness of 1 mm and a diameter of 1 cm discs, and then put the pressed discs in a crucible and calcined in a muffle furnace at 550°C for 2 hours to obtain tin dioxide microflakes with hexagonal morphology.

Embodiment 3

[0022] Weigh 0.9 g of dioctyltin oxide, 0.1 g of graphene, and 0.2 g of sublimed sulfur according to the mass ratio of 9:1:2. After the three substances are fully mixed for 10 minutes, press the mixture into several pieces with a thickness of 1 mm and a diameter of 1 cm. The discs were then placed in a crucible and calcined in a muffle furnace at 580° C. for 1.5 hours to obtain tin dioxide microflakes with hexagonal morphology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com