Temperature control system and method applied to spectrophotometer analysis instrument

A temperature control method and spectrophotometer technology, which are used in temperature control, control/regulation systems, material analysis by optical means, etc., can solve the problems of complex system design, sudden change in power load, and difficulty in rapid adjustment, and achieve system structure. Simple, widely used, stable output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

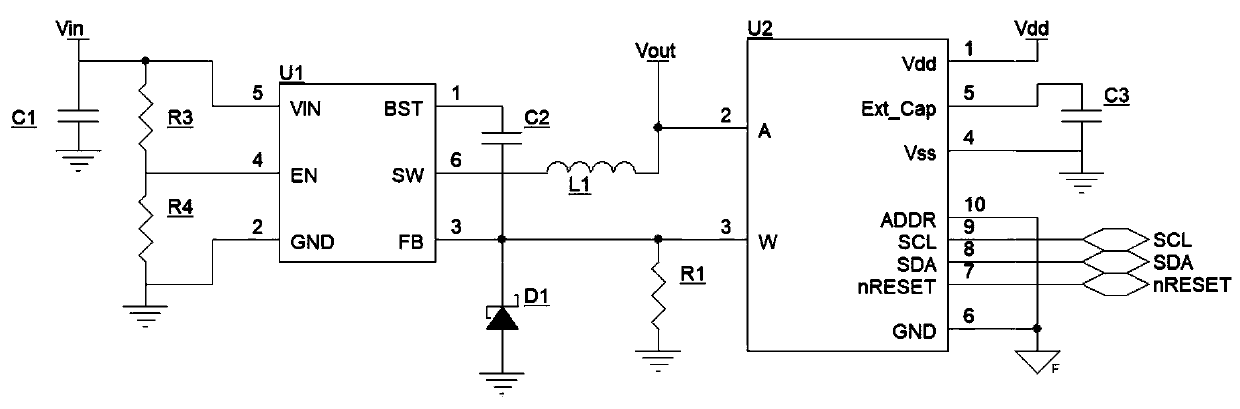

[0031] The temperature control system includes the following parts:

[0032] 1) Water pipe - the water pipe is the part of the heating component that contains the liquid. The cross-sectional area of the liquid inside it is S, and the length of the water pipe is L. In the instrument design stage, determine the values of S and L according to the site application requirements;

[0033] 2) Heating wire—the heating wire is wound on the water pipe, and the outside is protected by an insulating layer. It is used as a heating source to heat the liquid. The voltage at both ends is v, and the resistance is R. In the instrument design stage, determine the R value, as well as the maximum and minimum values of v according to the field application requirements;

[0034] 3) Power supply and control circuit—provide voltage for the heating wire. Here, an adjustable voltage source chip is used. The output voltage is determined by the ratio of two resistors, and can be adjusted between the...

Embodiment 2

[0082] When the liquid is still in the water pipe, the liquid is in a static state, and the steps and derivation formulas in Embodiment 1 are fully applicable. In the application process, the temperature control method includes the following steps:

[0083] 1) In the application state, measure and record the temperature rise-voltage relationship, fit the temperature rise-voltage relationship curve, and store the original data and curve formula in the programmable processor chip;

[0084] 2), according to the temperature rise-voltage relationship curve in step 1), apply the required temperature rise voltage, and heat up to the target temperature range;

[0085] 3), according to the temperature rise-voltage relationship curve in step 1), apply the required constant temperature voltage to keep the temperature within the target temperature range;

[0086] 4) The temperature sensor monitors the temperature of the heated liquid in real time, and the programmable processor chip adju...

Embodiment 3

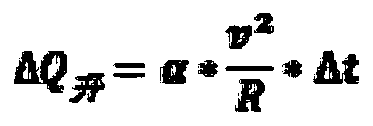

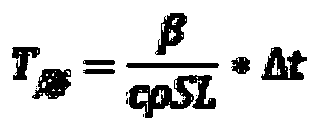

[0088] When the liquid in the water pipe starts to flow, the previous thermodynamic model needs to be further decomposed to determine the influencing factors. Consider the temperature rise of the liquid part entering the water pipe within a small time period Δt, as follows

[0089]

[0090] where A is the flow rate of the liquid, which is a constant in most applications.

[0091] It can be seen that when the liquid flows dynamically, on the basis of the various steps and derivation formulas in Example 1, the factors affecting the temperature difference increase the flow rate of a liquid.

[0092] In the application process, the temperature control method includes the following steps:

[0093] 1) Keeping the flow rate at different definite values, performing multiple measurements and recording, fitting each temperature rise-voltage relationship curve, and storing the original data and curve formula in the programmable processor chip;

[0094] 2), according to the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com