Closed-loop control system for three-dimensional micro-area electrochemical deposition

A closed-loop control, electrochemical technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of printing pattern interruption, microtubule blockage, deposition rate variation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

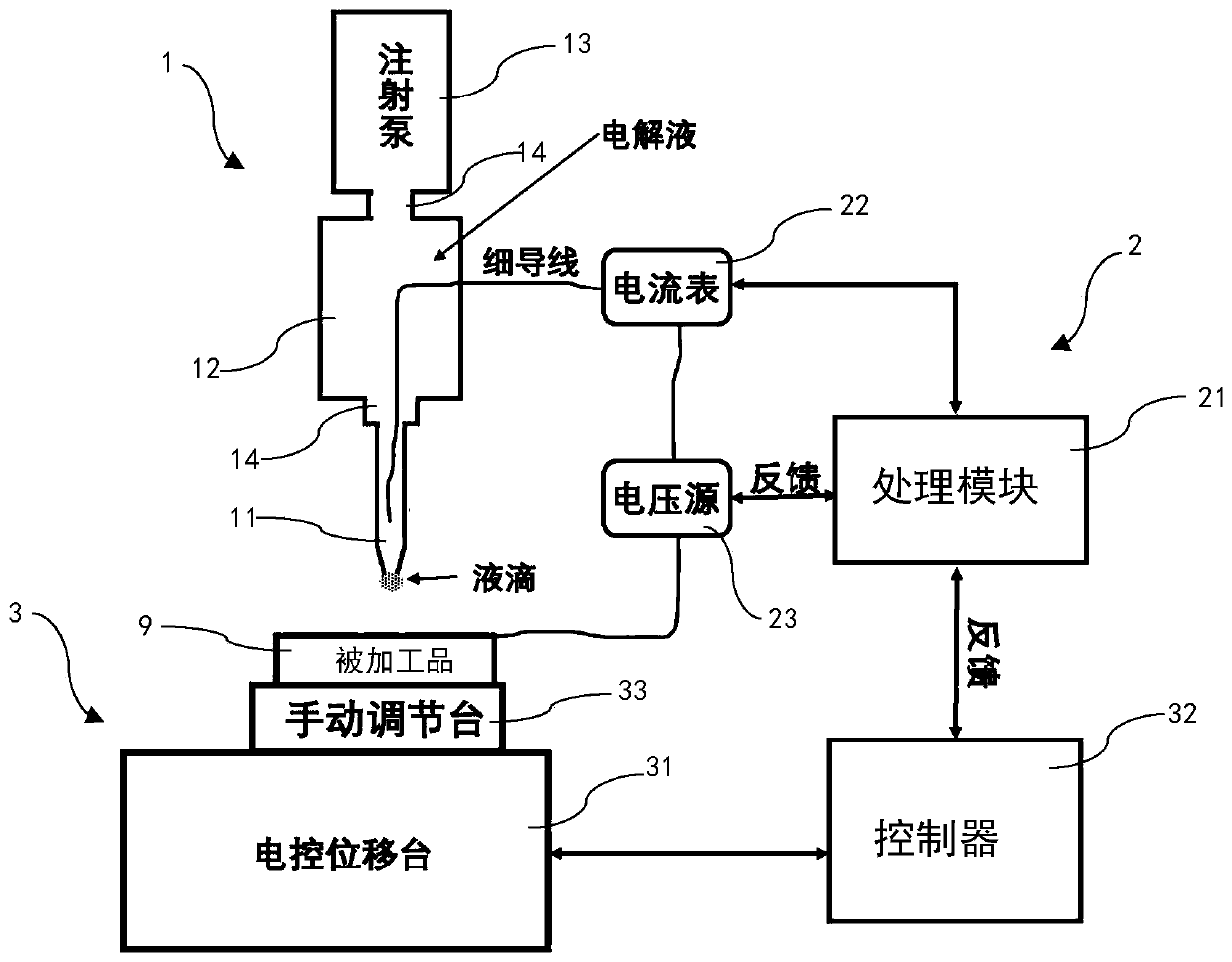

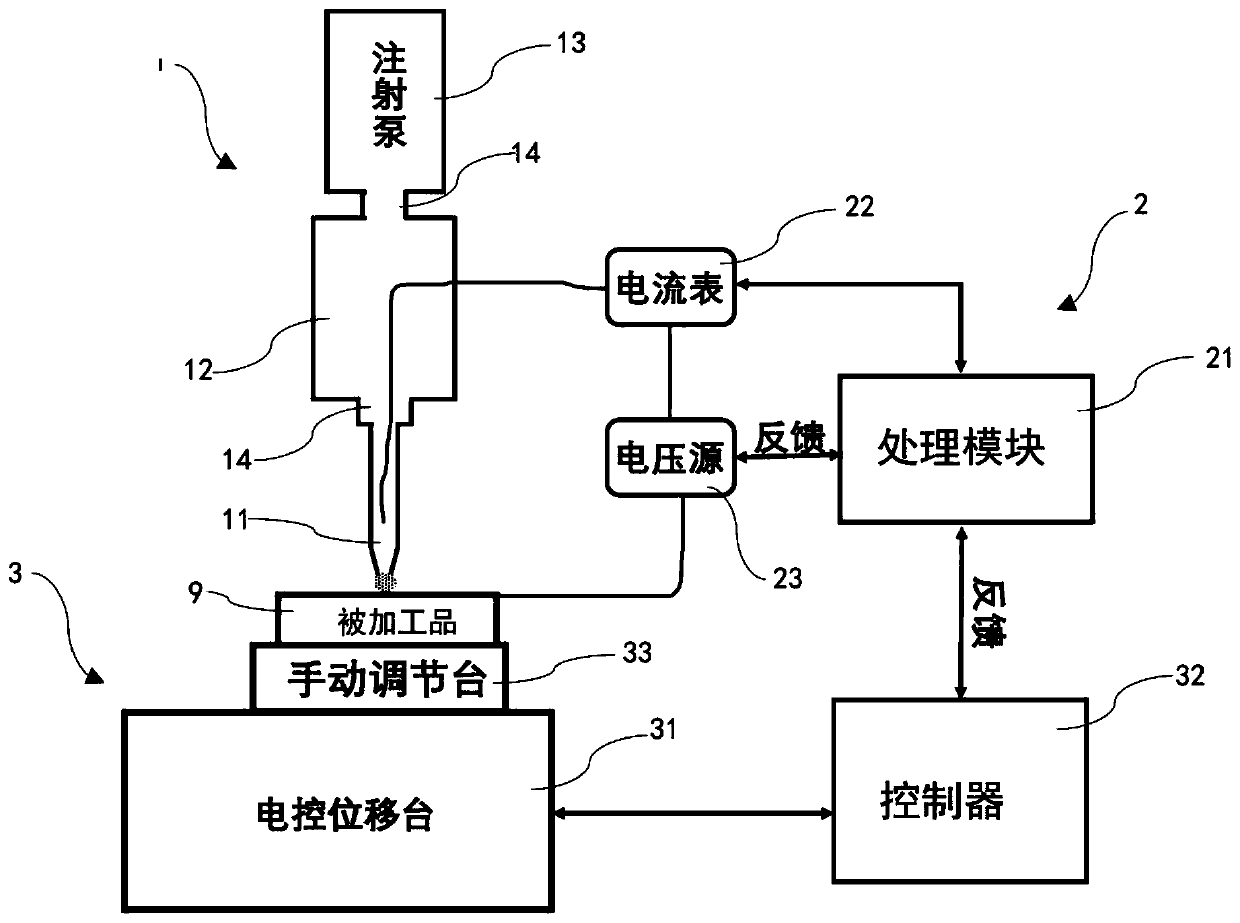

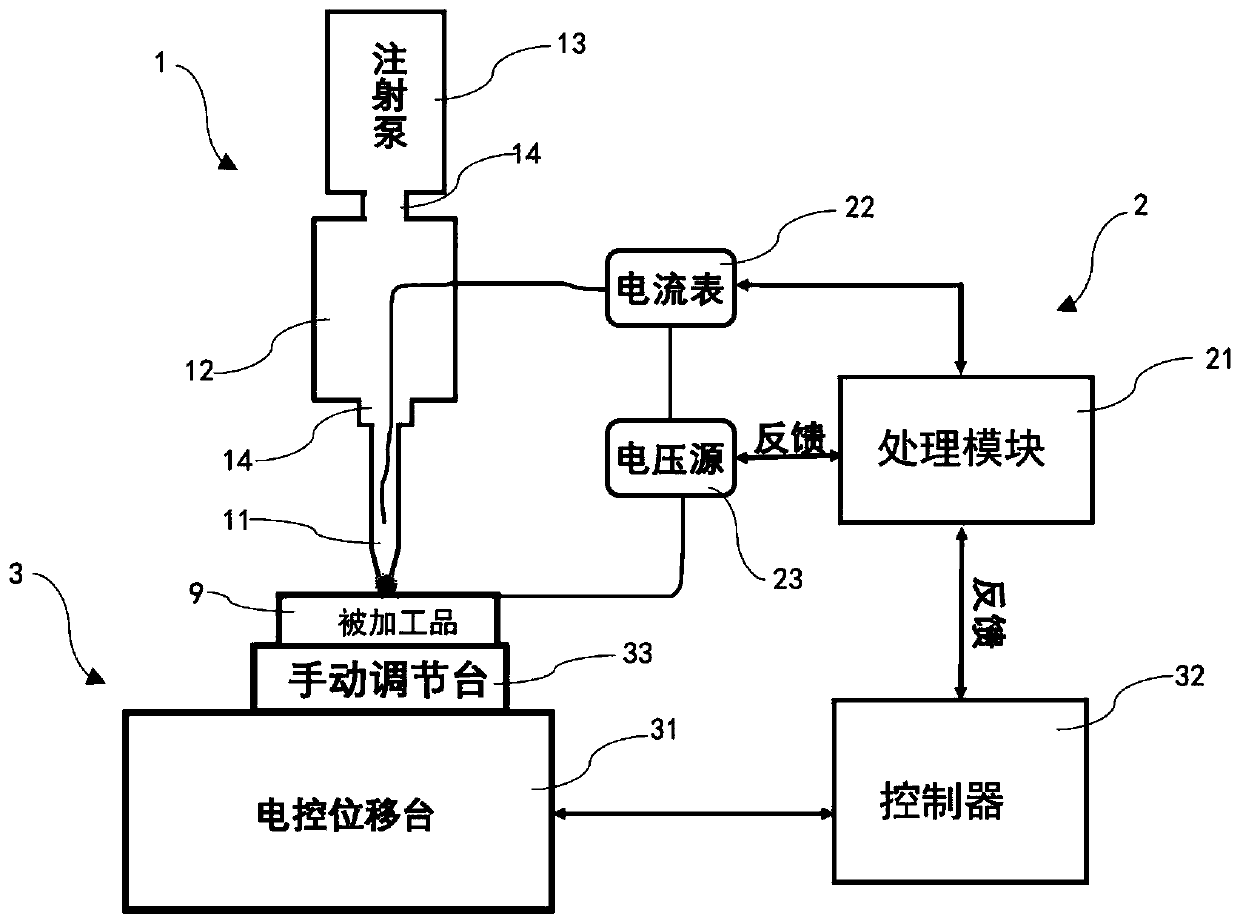

[0107] In this embodiment, taking the electrochemical deposition of copper micro-wires in the Z direction as an example, the operation of the closed-loop control system for the three-dimensional micro-area electrochemical deposition is introduced.

[0108] The electrolyte used was 0.05M copper sulfate aqueous solution. The microtube 11 used is a glass capillary with an outer diameter of 1.5 mm and an inner diameter of 0.85 mm. The capillary is sharpened through a melting stretching process, and the diameter of the tip after processing is about 3 microns. The capillary was perfused with an aqueous solution of copper sulfate. The processed product 9 is a glass slide coated with a gold layer. During the deposition process, the gold layer is grounded, and a bias voltage is applied to the copper wire inserted into the electrolytic solution. as per figure 1 Connect the parts as shown.

[0109] When the tip of the capillary is close to the surface of the processed product, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com