A ska ultra-broadband refrigeration miniaturized four-ridge horn feed and its application

A four-ridged horn, ultra-wideband technology, applied in the directions of waveguide horns, electrical components, circuits, etc., can solve the problem that the antenna cannot meet the requirements, and achieve the effect of eliminating standing wave discontinuity, good compactness, and realizing broadband characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

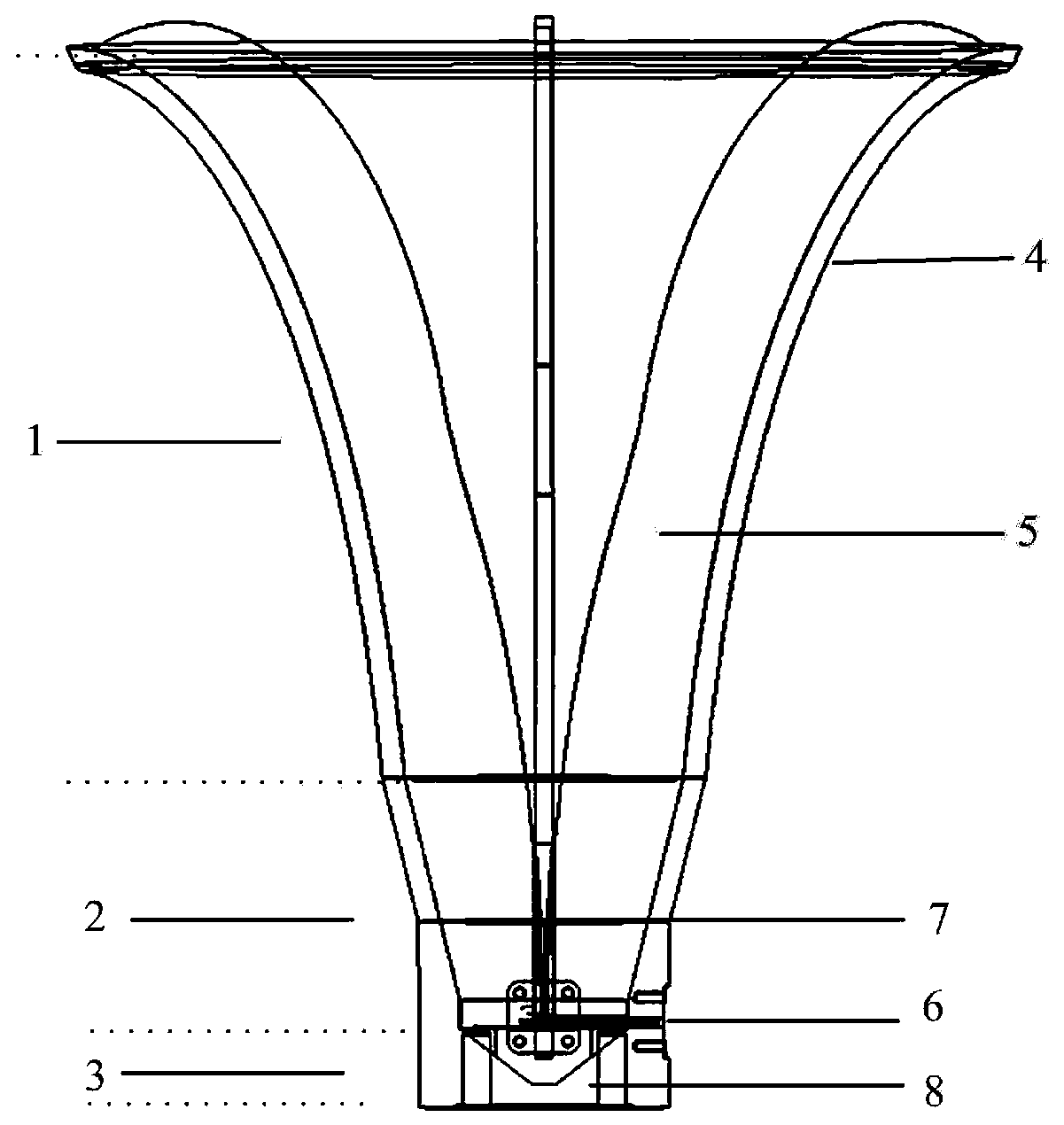

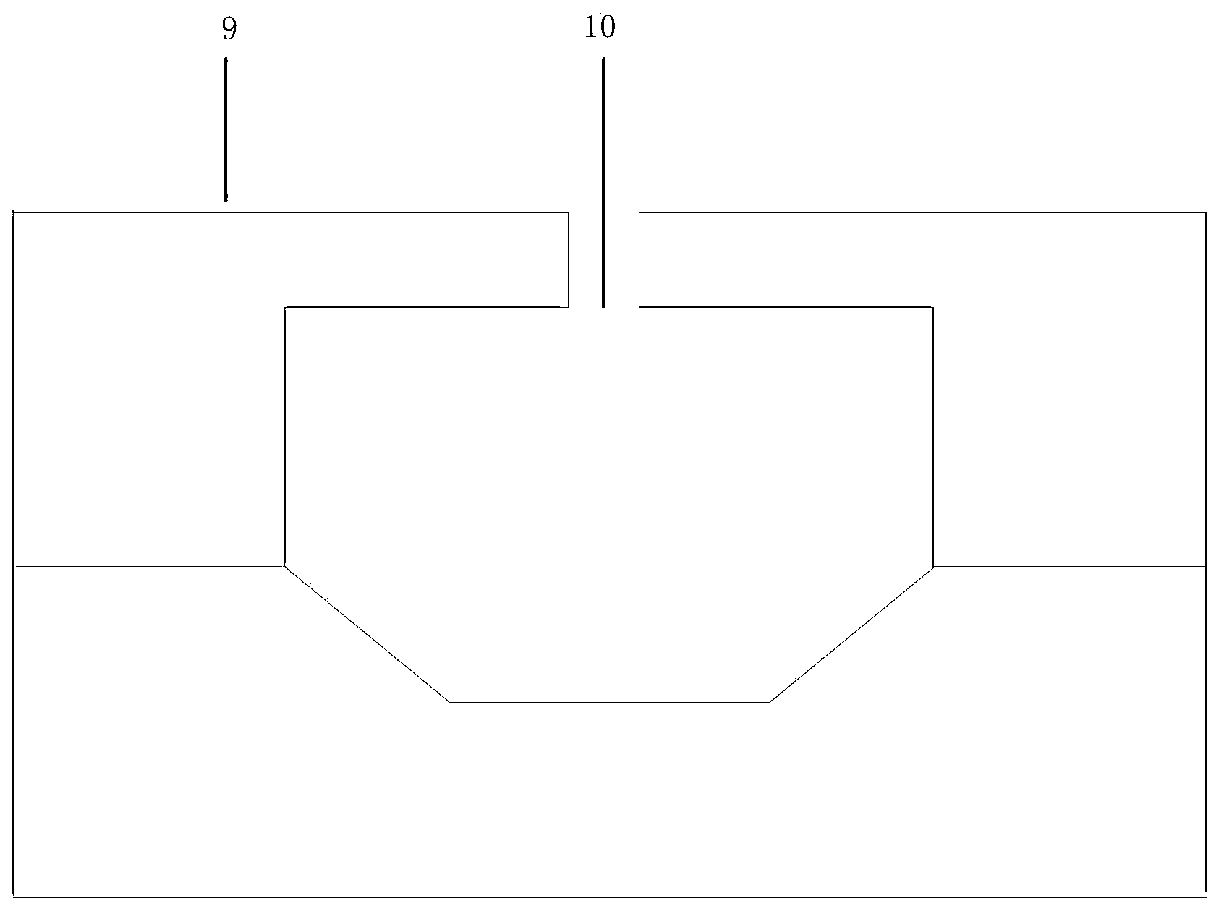

[0040] see figure 1 , a SKA ultra-broadband refrigeration miniaturized four-ridge horn feed source of the present invention, the feed source operating frequency range is 2.4-24GHz, including a conical horn 1, a four-ridge circular waveguide 2, a straight waveguide 3, a horn outer wall 4, and a ridge piece 5 , the first coaxial probe 6 , the second coaxial probe 7 , and the short-circuit reflection cavity 8 .

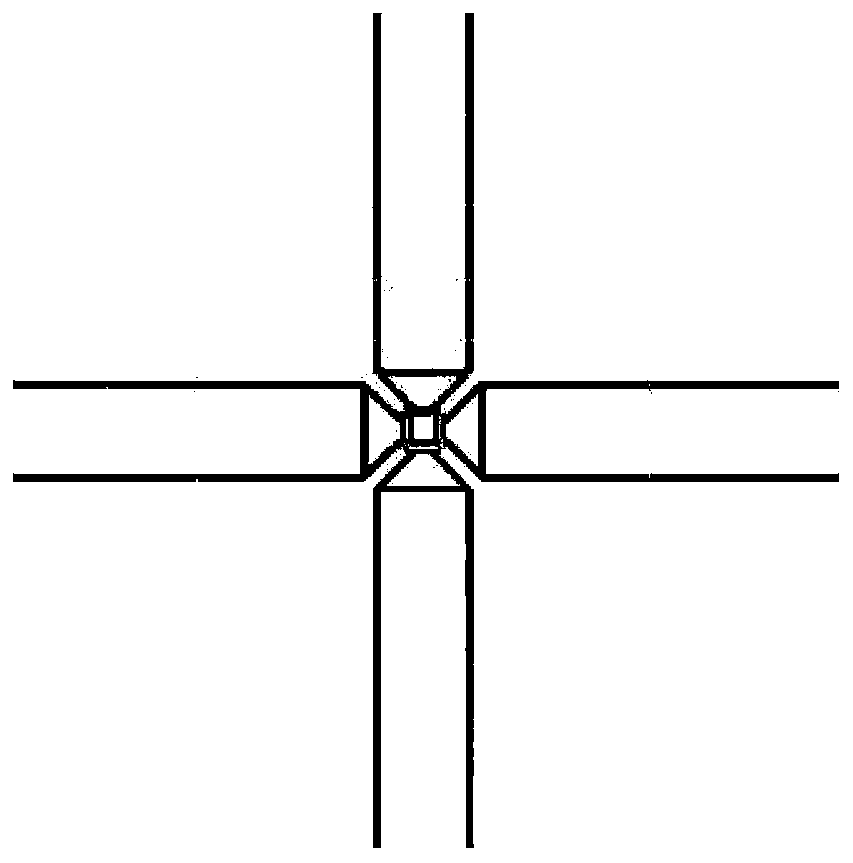

[0041] One end of the four-ridge circular waveguide 2 is connected to the conical horn 1 , and the other end is connected to the short-circuit reflecting cavity 8 . The horn diameter of the cone horn 1 and the length of the horn section determine the radiation characteristics of the dual-polarized horn antenna. The horn section mainly includes the horn outer wall 4 and four orthogonal ridges 5, and the horn outer wall 4 is loaded o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com