A New Heat Dissipating Electric Spindle

A technology of electric spindles and spindles, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of damage to electric spindles, easy oil leakage, high production costs, etc., and achieve improved heat conduction and heat dissipation performance, simple overall structure and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

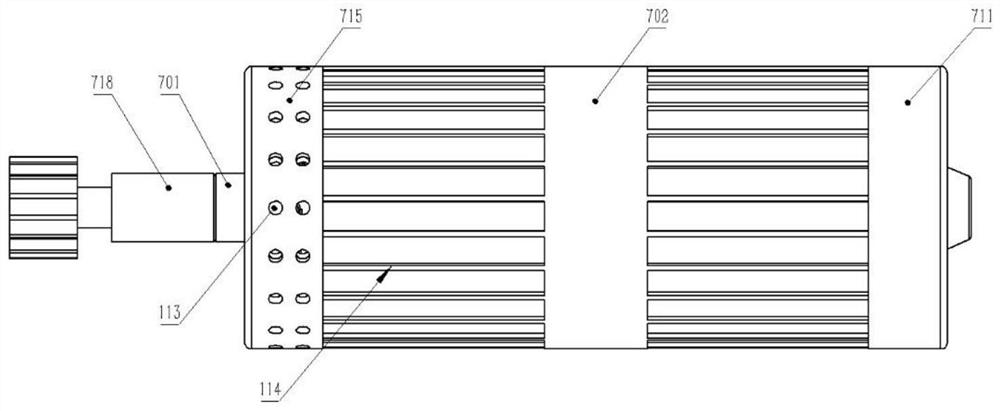

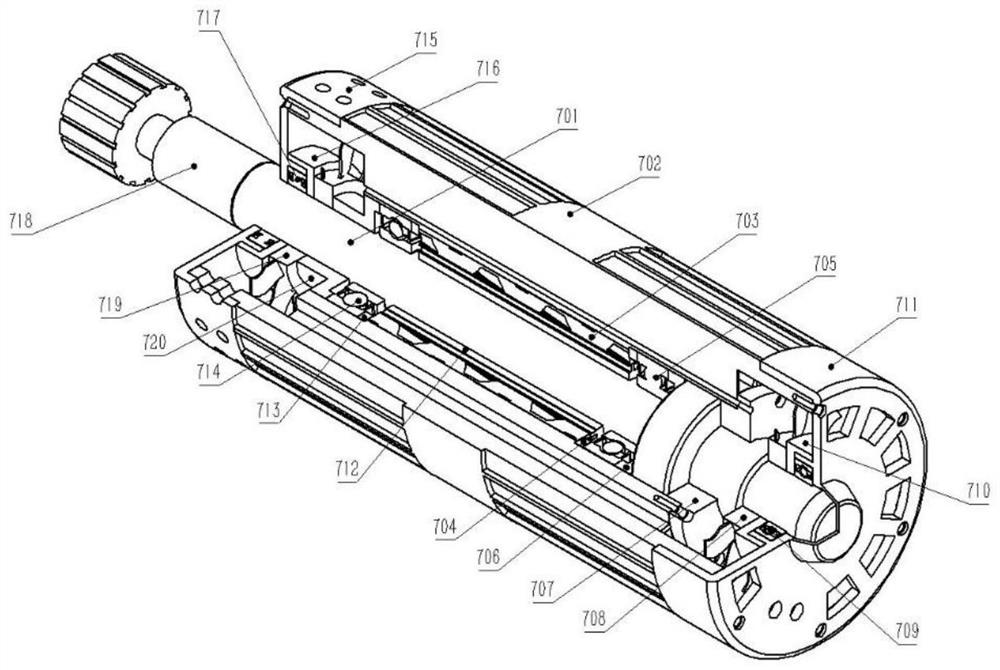

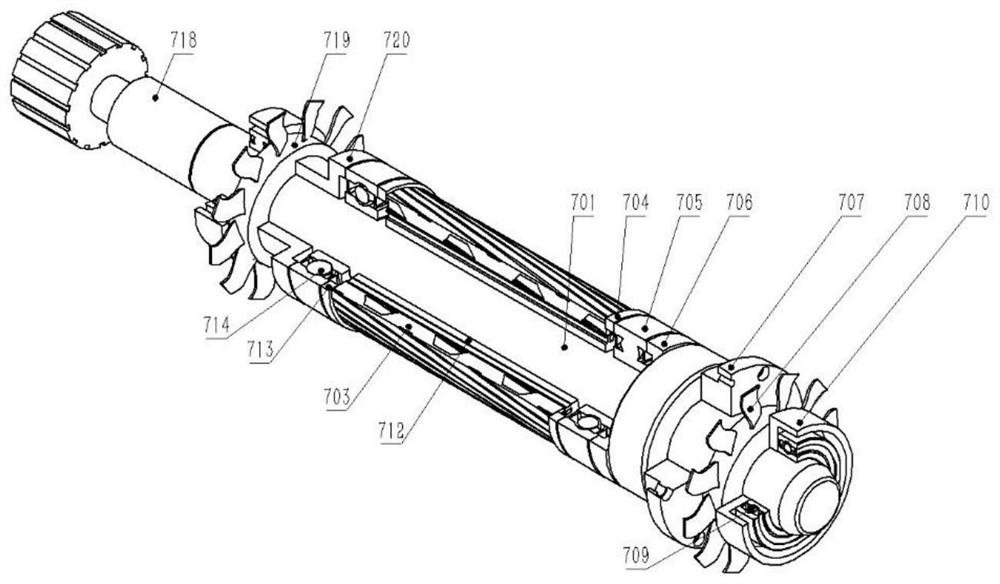

[0030] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. For ease of description, in this embodiment, the position where the ventilation end cover II is located is defined as "front", and the position where the ventilation end cover I is located is defined as "rear".

[0031] see Figure 1 to Figure 4 In this embodiment, a new heat-dissipating electric spindle includes a spindle 701, a ventilated shell 702 made of brass, a stator 703, four bearings, three washers, and a lock nut 707, which are made of 1Cr12Mo heat-resistant steel or chromium alloy or Two cooling fans, two sealing rings, two ventilation end covers, and rotors made of titanium alloy are manufactured through lathe processing, forging, milling, etc. The surface strength hardening treatment is carried out on the blades of the heat dissipation fan. The specific assembly relationship of each part is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com