Physicochemical coagulation-defluorination-precipitation integrated wastewater treatment method

A wastewater treatment and coagulation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water treatment parameter control, etc. It can solve the problems of long treatment process, large area of treatment equipment, and high system operating costs. , to achieve the effect of reducing floor area, reducing system operating costs, and reducing construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

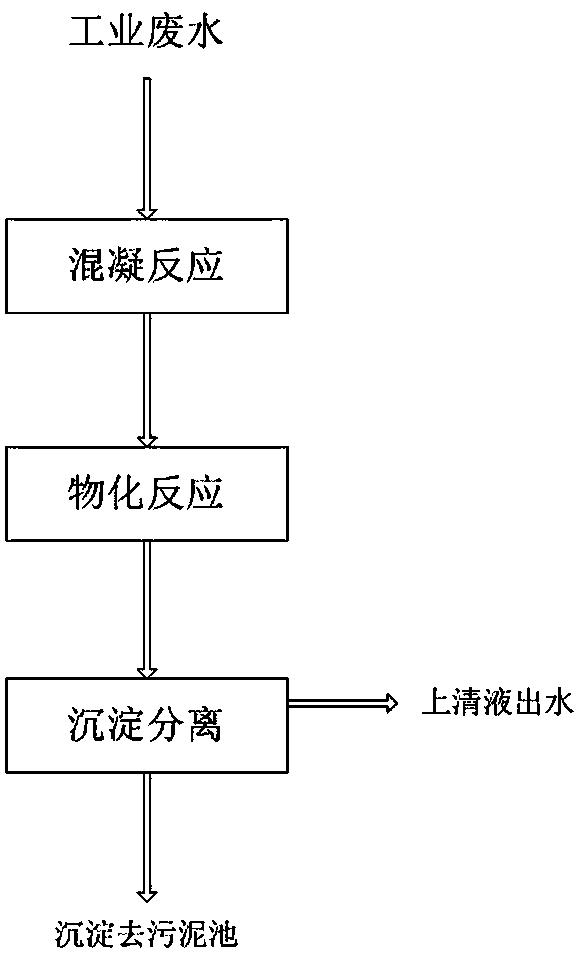

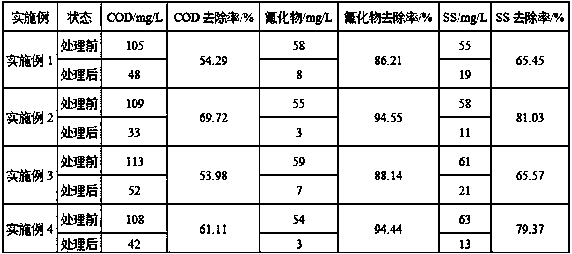

[0023] A kind of waste water treatment method integrated with physicochemical coagulation, fluorine removal and precipitation, the waste water is coking waste water, COD is 105 mg / L, fluoride is 58 mg / L, SS is 55 mg / L before treatment, see figure 1 , including the following steps:

[0024] Step 1. Coagulation reaction: add PAC aluminum salt coagulant and PAM flocculant to industrial wastewater and stir, the addition of PAC aluminum salt coagulant is 180 ppm, and the addition of PAM flocculant is 5 ppm;

[0025] Step 2. Physicochemical reaction: Add slaked lime defluorinating agent to the industrial wastewater stirred in step 1 and stir again. The molar ratio of calcium to fluorine in the slaked lime defluorinating agent is 1:1.2;

[0026] Step 3. Sedimentation and separation: The mixture stirred in step 2 is subjected to sedimentation and separation. The sedimentation separation adopts a sloping plate sedimentation tank, the residence time of sewage is 65 minutes, and the surf...

Embodiment 2

[0028] A kind of waste water treatment method integrated with physicochemical coagulation, fluorine removal and precipitation, the waste water is coking waste water, COD is 109 mg / L, fluoride is 55 mg / L, SS is 58 mg / L before treatment, see figure 1 , including the following steps:

[0029] Step 1. Coagulation reaction: add PAC aluminum salt coagulant and PAM flocculant to industrial waste water and stir, the addition amount of described PAC aluminum salt coagulant is 200 ppm, the addition amount of PAM flocculant is 6 ppm;

[0030] Step 2. Physicochemical reaction: Add slaked lime defluorinating agent to the industrial wastewater stirred in step 1 and stir again. The molar ratio of calcium to fluorine in the slaked lime defluorinating agent is 1:1.5;

[0031] Step 3. Sedimentation and separation: The mixture stirred in step 2 is subjected to sedimentation and separation. The sedimentation separation adopts a sloping plate sedimentation tank, the residence time of sewage is 65 ...

Embodiment 3

[0033] A kind of waste water treatment method integrated with physicochemical coagulation, fluorine removal and precipitation, the waste water is coking waste water, COD is 113 mg / L, fluoride is 59 mg / L, SS is 61 mg / L before treatment, see figure 1 , including the following steps:

[0034] Step 1. Coagulation reaction: add iron salt coagulant and PAM flocculant to industrial waste water and stir, the addition of described iron salt coagulant is 800 ppm, the addition of PAM flocculant is 5 ppm;

[0035] Step 2. Physicochemical reaction: add calcium chloride defluoride agent to the industrial wastewater stirred in step 1 and stir again, the molar ratio of calcium to fluorine in the calcium chloride defluoride agent is 1:1.2;

[0036] Step 3. Sedimentation and separation: The mixture stirred in step 2 is subjected to sedimentation and separation. The sedimentation and separation adopts an inclined plate sedimentation tank, and the residence time of sewage is 65 minutes. The clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com