A kind of soil heavy metal deactivator and preparation technology thereof

A heavy metal passivator and preparation technology, which is applied in the field of contaminated soil remediation, can solve the problems of inconvenient operation for workers, secondary soil damage, hardening, etc., and achieve the effect of improving practicability, working effect and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

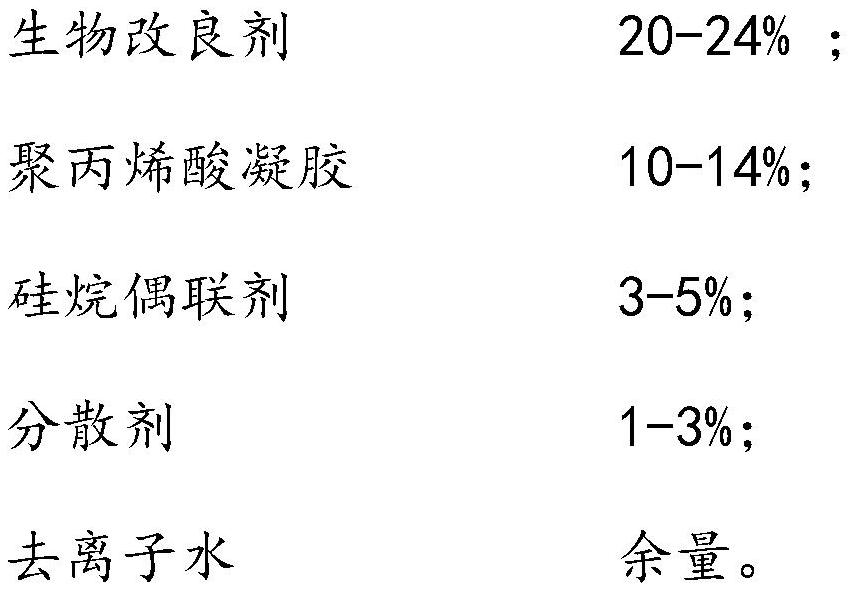

Method used

Image

Examples

Embodiment 1

[0048] The invention discloses a preparation process of a soil heavy metal passivator, which comprises the following preparation process:

[0049] S1: Preparation of modified carrier filler: Mix 51% deionized water, 3% anionic surfactant and 6% nonionic surfactant, then stir at 35°C and 1000r / min for 20min; then add 40 % biochar, and stirred under the condition of 1500r / min for 30min; finally, the mixture was dried at room temperature, and ground and sieved to obtain a modified carrier filler with a particle size of 100 microns;

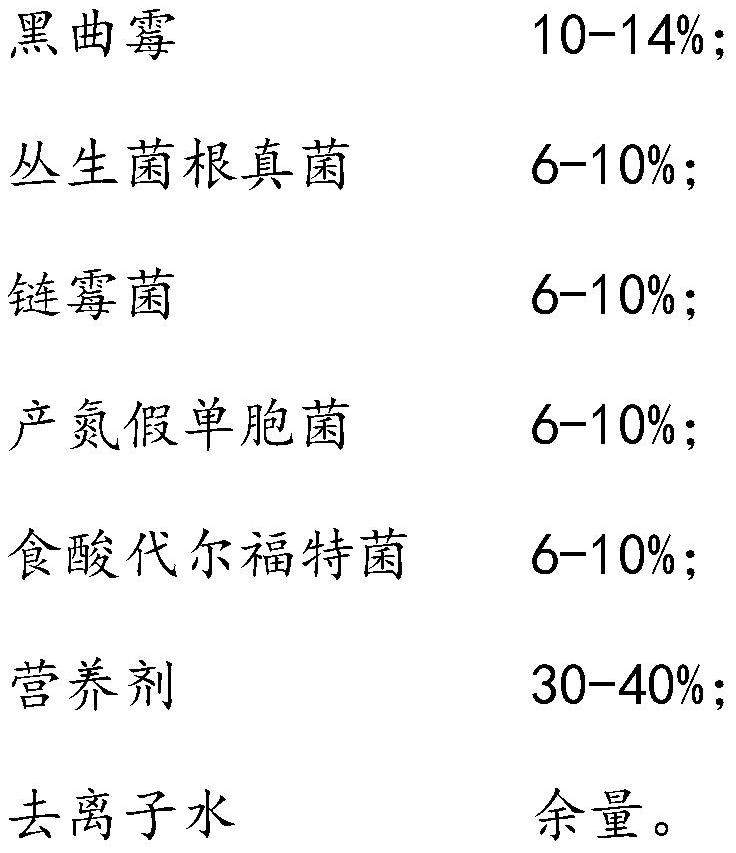

[0050] Preparation of bio-improvement agent: 14% of Aspergillus niger, 6% of mycorrhizal fungi, 6% of Streptomyces, 6% of Pseudomonas azogenes, 6% of Delftia acidovorans, 40% of After the agent and 22% deionization are mixed evenly, the bio-improvement agent is prepared;

[0051] The nutritional agent comprises the following components in weight percentage: 30% of peptone, 40% of pH regulator, 6% of sodium chloride, 1% of magnesium sulfate and 23% o...

Embodiment 1

[0061] The difference between Examples 10-13 and Example 1 is that the nutrient includes the following components in weight percent:

[0062]

[0063] The difference between Examples 14-17 and Example 1 is that the pH regulator includes the following raw materials in weight percent:

[0064]

[0065]

[0066] The difference between Examples 18-21 and Example 1 is that the modified carrier filler comprises the following components in weight percent:

[0067]

[0068] The difference between Embodiment 22-25 and Embodiment 1 is that the particle size of modified carrier filler and soil heavy metal deactivator is as shown in the table below:

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com