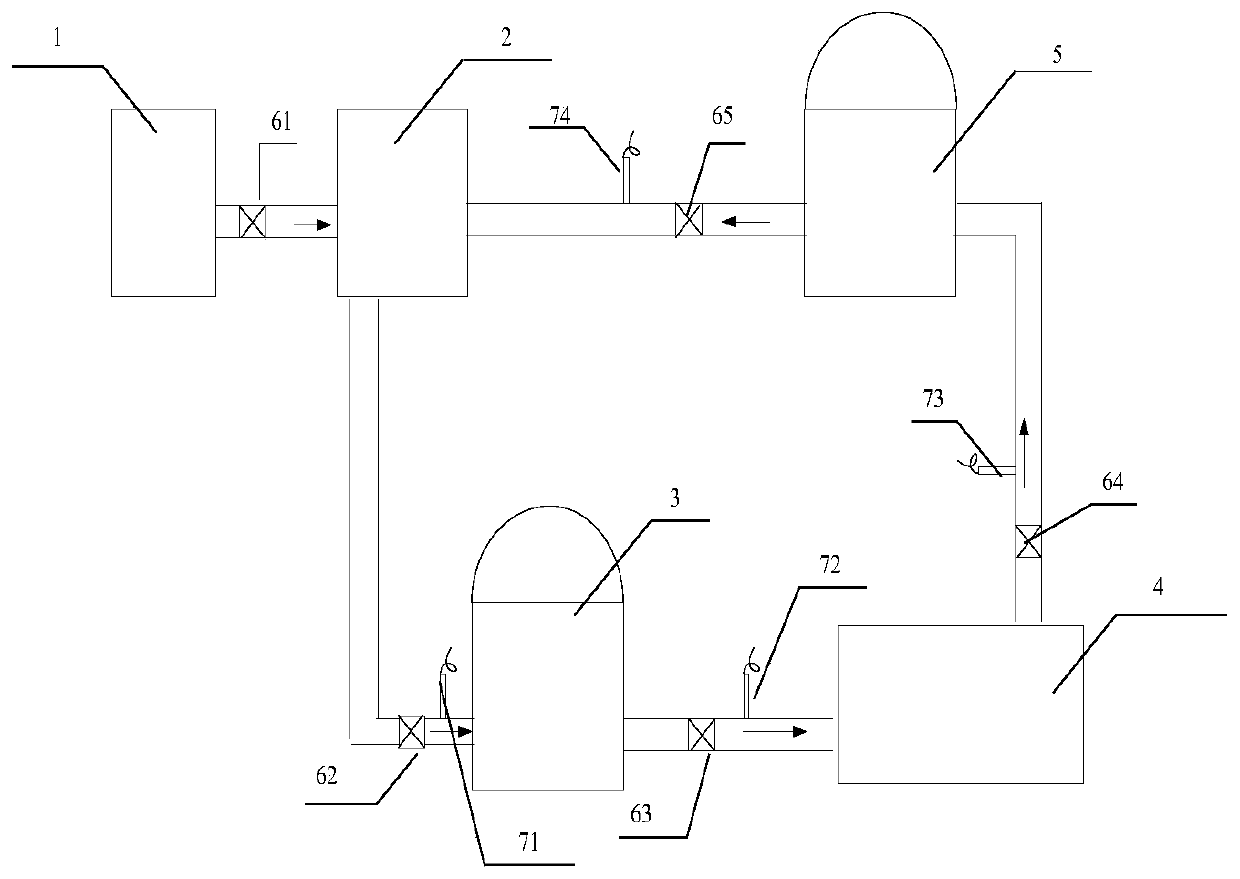

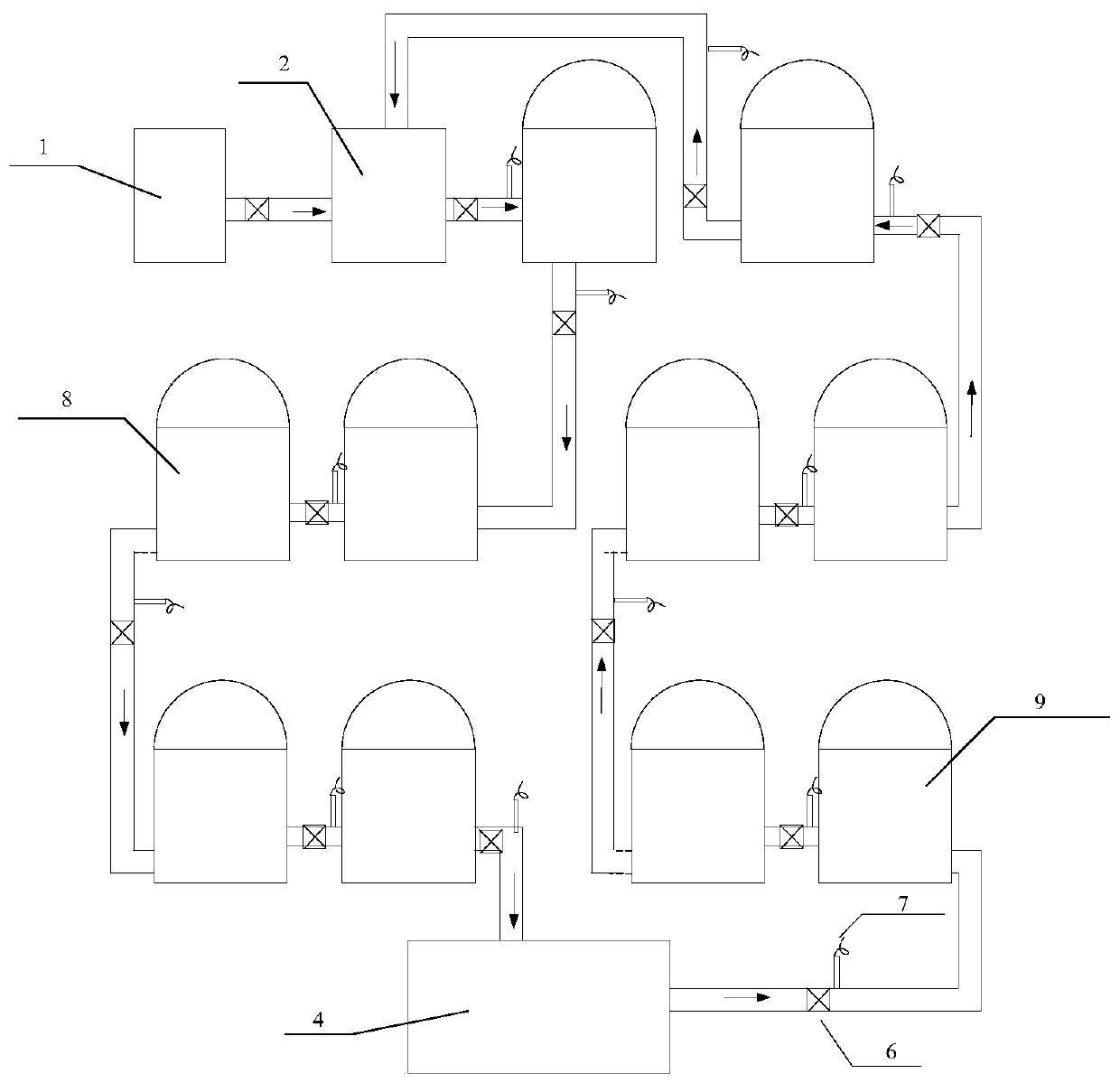

Hydrogen oil transportation system

A technology of hydrogen oil and oil recovery, which is applied in pipeline system, fluid treatment, gas treatment/storage, etc., and can solve problems such as the imbalance between supply and demand of hydrogen energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] The specific embodiment is as follows: the comparison circuit acquires the pipeline flow values of the third flowmeter 73 and the second flowmeter 72, and calculates the pipeline flow of the third flowmeter 73 minus the second flowmeter 72 difference and send the difference in pipe flow to the trigger circuit. The trigger circuit receives the pipeline flow difference information, if the difference reaches the threshold -5m 3 , the trigger circuit triggers the switch of the second solenoid valve 62 to open the second solenoid valve 62 so that the hydrogen oil in the hydrogenation device 2 flows to the hydrogen oil filling station 4 . When the pipeline flow difference is less than the threshold -5m 3 , the second solenoid valve 62 is closed. The control details between other flowmeters and solenoid valves are similar to this according to the relationship between the hydrogen oil outflow and inflow of the device, and will not be repeated one by one.

[0047] The diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com