Vertical structure LED integrated with DBR and forming method thereof

A vertical structure, conductive substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low photoelectric conversion efficiency, slow LED response speed, etc., to improve electro-optical conversion efficiency, waveguide mode suppression, and improve light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation of the DBR-integrated vertical structure LED provided by the present invention and its forming method will be described in detail below with reference to the accompanying drawings.

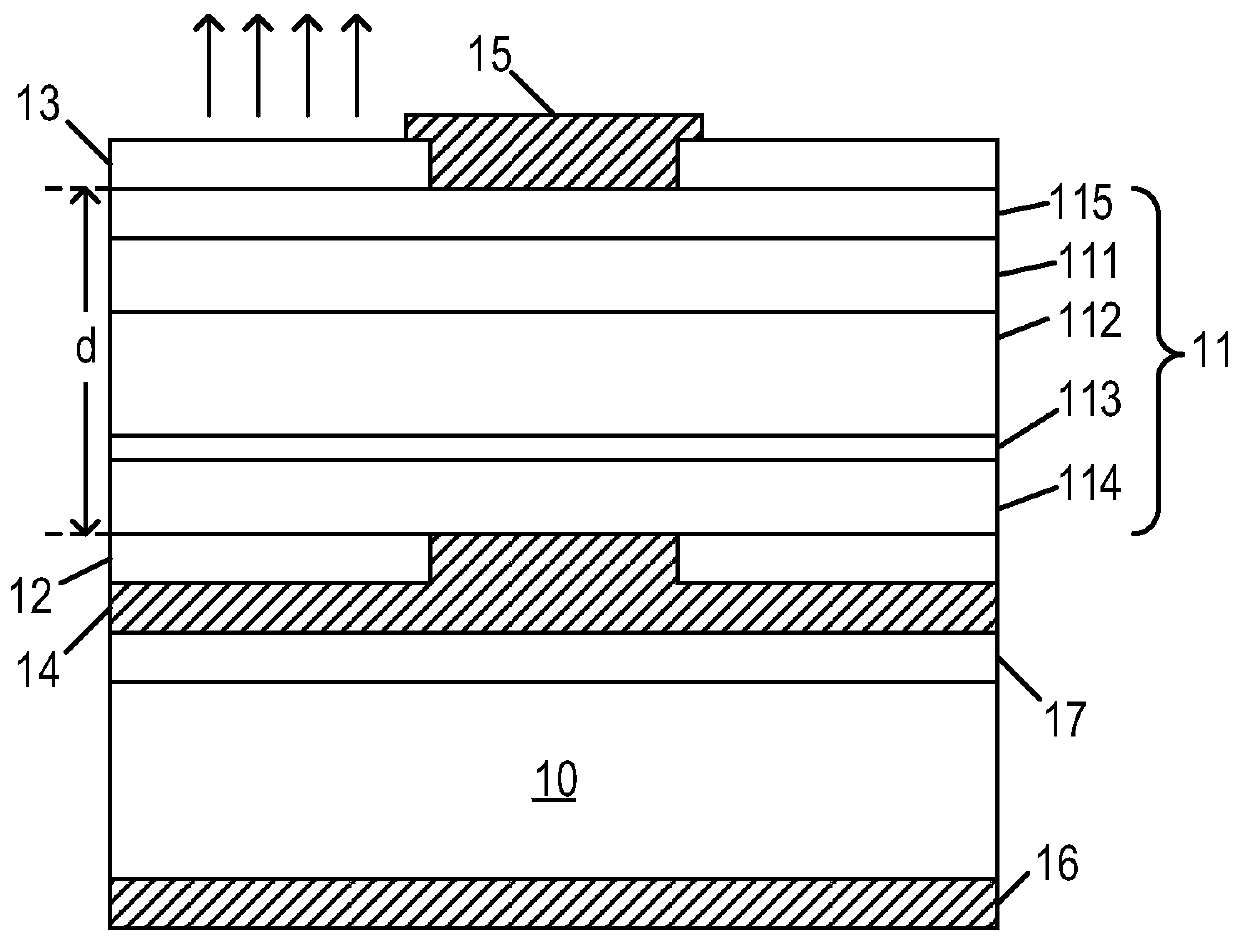

[0048] This specific embodiment provides a vertical structure LED integrating DBR (Distributed Bragg Reflector, distributed Bragg reflector), with figure 1 It is a structural schematic diagram of a vertical structure LED integrated with a DBR in a specific embodiment of the present invention. Such as figure 1 As shown, the vertical structure LED integrated DBR provided in this specific embodiment includes:

[0049] a conductive substrate 10 having a first surface and a second surface opposite to the first surface;

[0050] A first DBR layer 12 located on the first surface of the conductive substrate 10;

[0051] The epitaxial layer 11, located on the first DBR layer 12, includes a first contact layer 115, a quantum well layer 112 and a second contact layer 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com