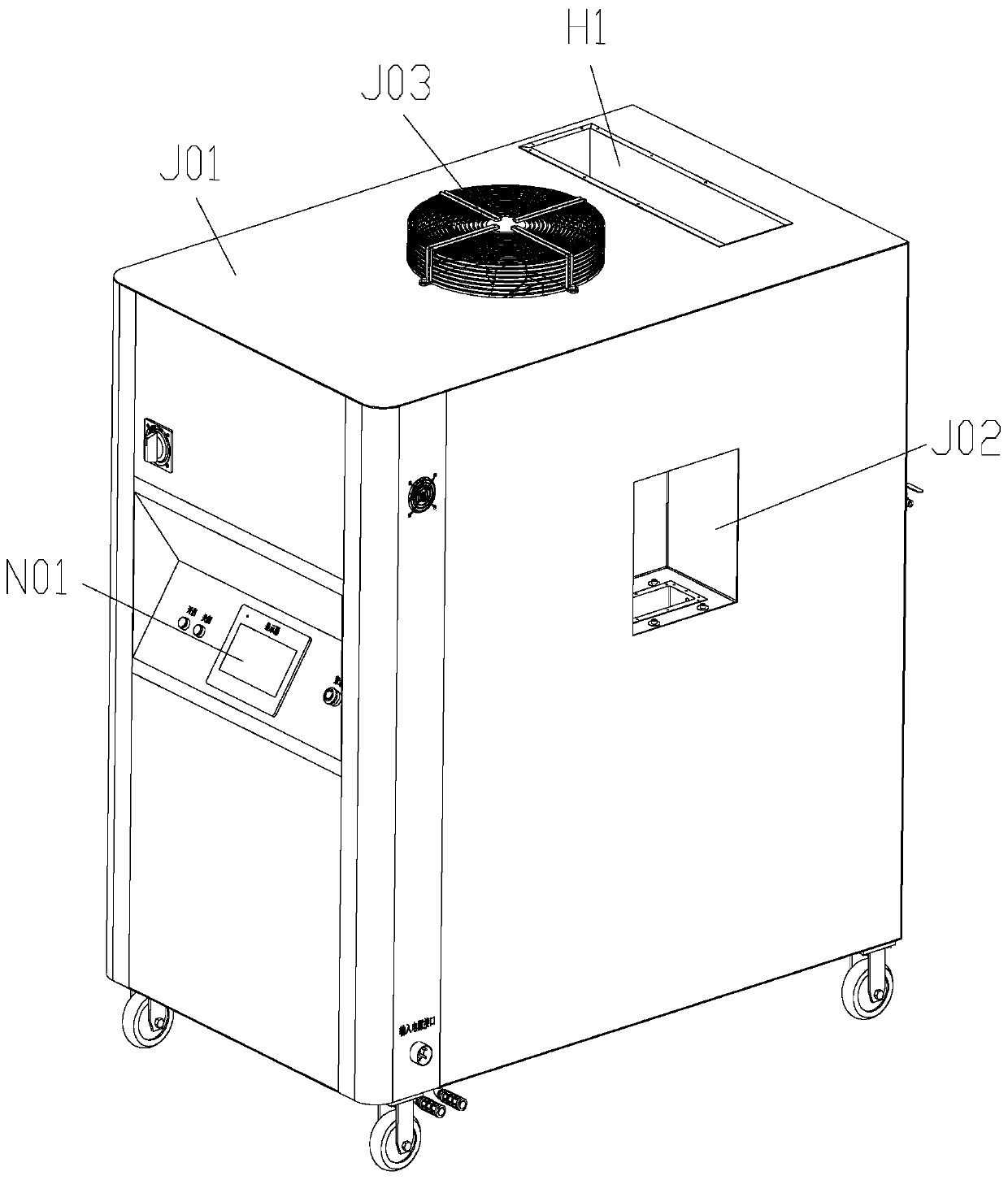

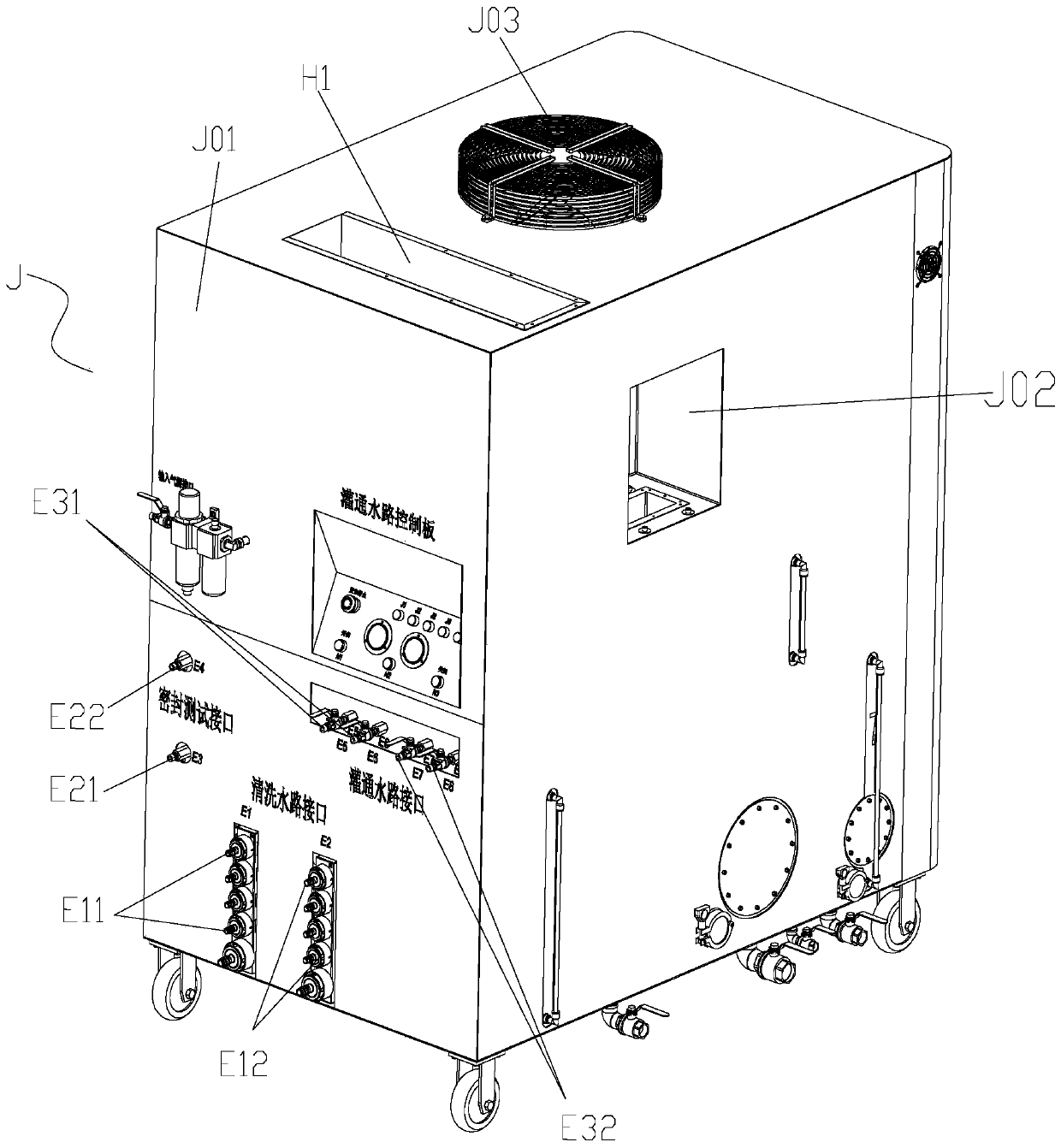

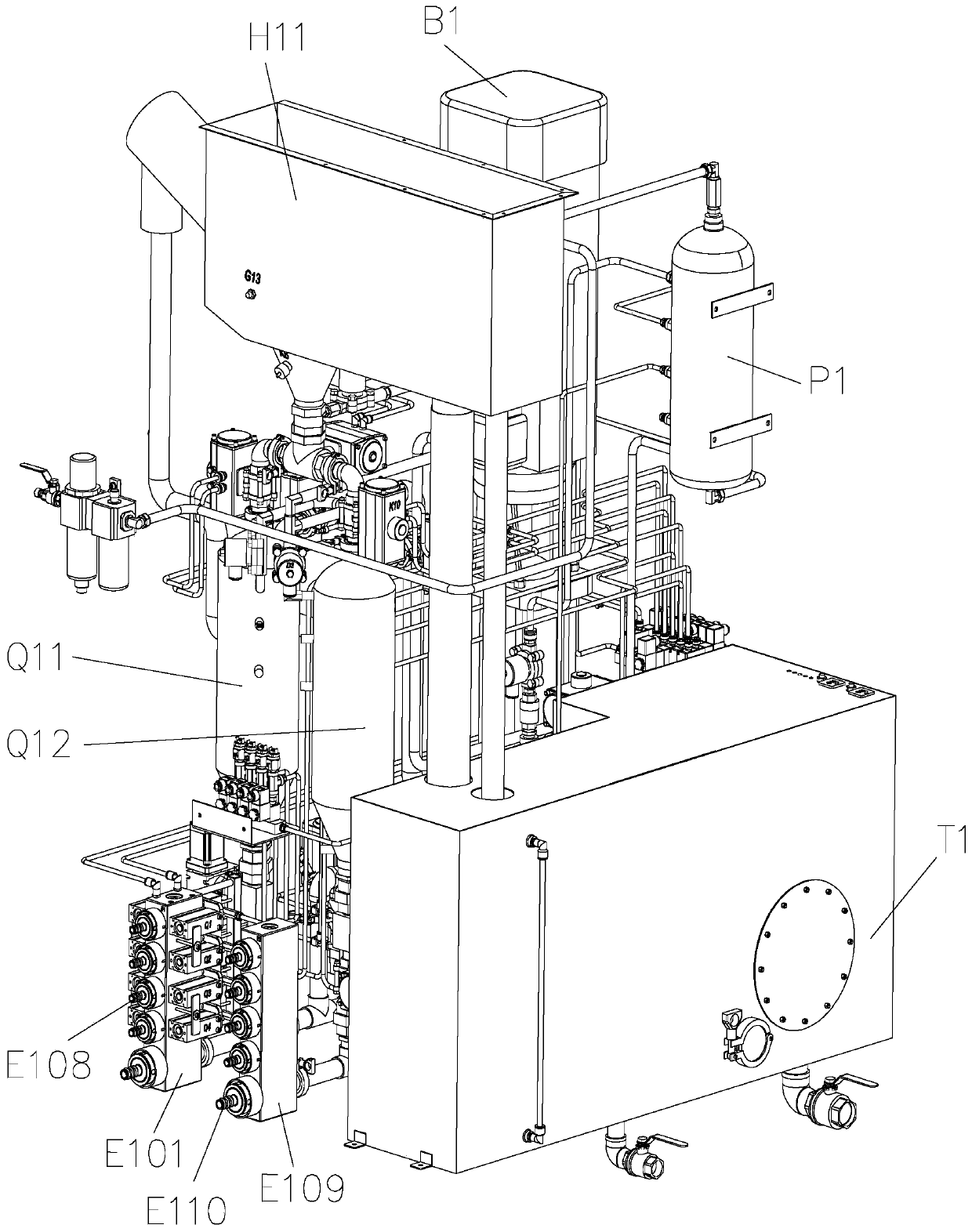

Multifunctional pipe cleaning machine

A pipe cleaning and multi-functional technology, applied in the direction of cleaning hollow objects, cleaning methods and appliances, testing of machines/structural components, etc., can solve problems such as easy to pollute the environment, reduce operating efficiency, and itchy skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above purpose and means of the present invention and the effects thereof will be described in more detail in conjunction with the accompanying drawings, so that those who have certain knowledge in the technical field of the present invention can easily implement the technical ideas of the present invention. The terminology used herein is to describe the embodiment, not to limit the present invention. Among them, it should be pointed out that the "connection" mentioned in this article includes but is not limited to the structural connection relationship, signal connection relationship, etc. between the constituent elements. Pipelines that transport gaseous, liquid or solid fluids are directly or indirectly "connected" or "continuous"; Direct or indirect on or off through devices such as "valve"; "control connection" mentioned in this article generally refers to direct or indirect connection between components such as signal connection, data connection and communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com