Method for preparing Gd2Zr2O7 transparent ceramic

A technology of transparent ceramics and ceramics, applied in the field of ceramic materials, can solve the problems of complex operation process and affecting process repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

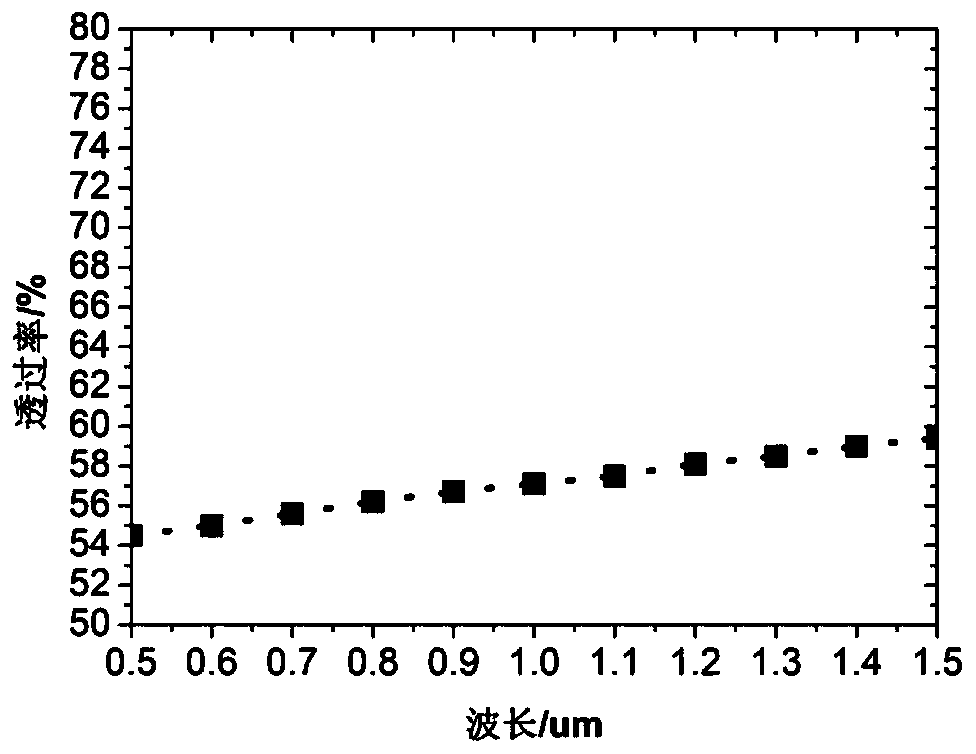

Embodiment 1

[0025] A preparation of Gd 2 Zr 2 o 7 The method for transparent ceramics is characterized in that it comprises the following steps:

[0026] Step 1: Weigh Gd 2 o 3 , ZrO 2 A total of 50 grams of raw materials, with YF 3 The powder is a sintering aid and is reserved for use. in:

[0027] The Gd 2 o 3 , ZrO 2 The masses of are respectively 29.75 grams and 20.25 grams;

[0028] The YF 3 The mass of powder is Gd 2 o 3 , ZrO 2 0.1% (ie 0.05 g) of the total mass of the powder;

[0029] Step 2: Mix the above three powders and pour them into a nylon tank together, then add pure water and dispersant in turn, and perform ball milling to obtain a slurry. in:

[0030] The mass ratio of the pure water to the mixed powder is 1:1 (ie 50 grams);

[0031] The dispersant is commercially available byk190, and the added amount is 0.5% (that is, 0.25 g) of the raw material mass.

[0032] The ball mill mixing refers to the method of adopting planetary ball mill treatment, the ba...

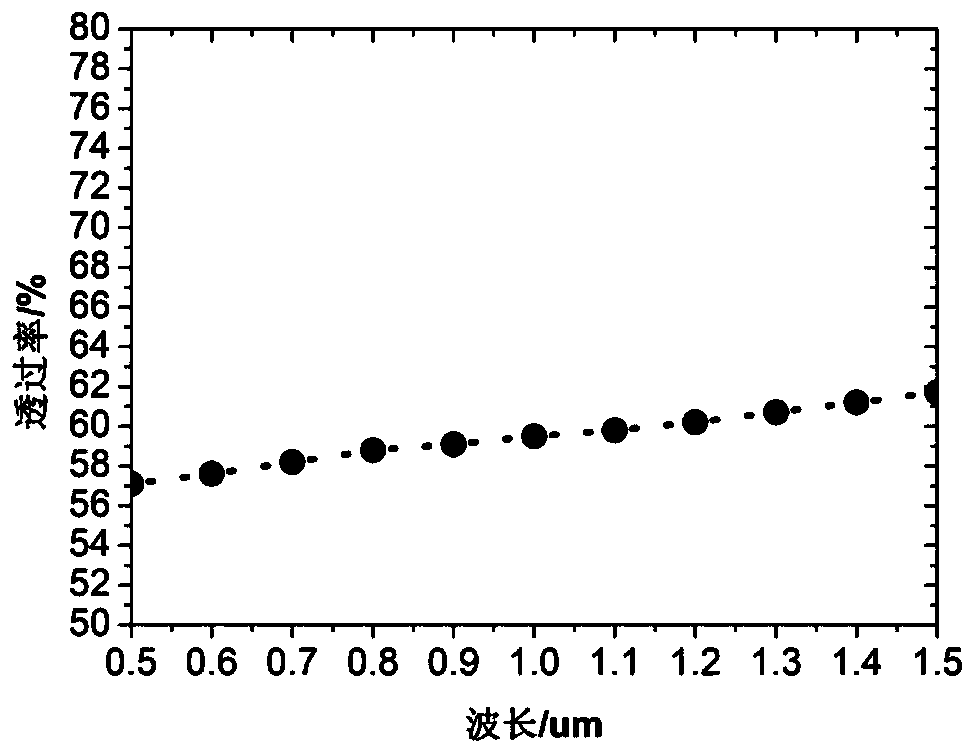

Embodiment 2

[0040] A preparation of Gd 2 Zr 2 o 7 The method for transparent ceramics is characterized in that it comprises the following steps:

[0041] Step 1: Weigh Gd 2 o 3 , ZrO 2 A total of 50 grams of raw materials, with YF 3 The powder is a sintering aid and is reserved for use. in:

[0042] The Gd 2 o 3 , ZrO 2 The masses of are respectively 29.75 grams and 20.25 grams;

[0043] The YF 3 The mass of powder is Gd 2 o 3 , ZrO 2 0.2% (ie 0.10 g) of the total mass of the powder;

[0044] Step 2: Mix the above three powders and pour them into a nylon tank together, then add pure water and dispersant in turn, and perform ball milling to obtain a slurry. in:

[0045] The mass ratio of the pure water to the mixed powder is 2:1 (i.e. 100 grams);

[0046] The dispersant is commercially available byk190, and the added amount is 0.5% (that is, 0.25 g) of the raw material mass.

[0047] The ball mill mixing refers to the method of adopting planetary ball mill treatment, the...

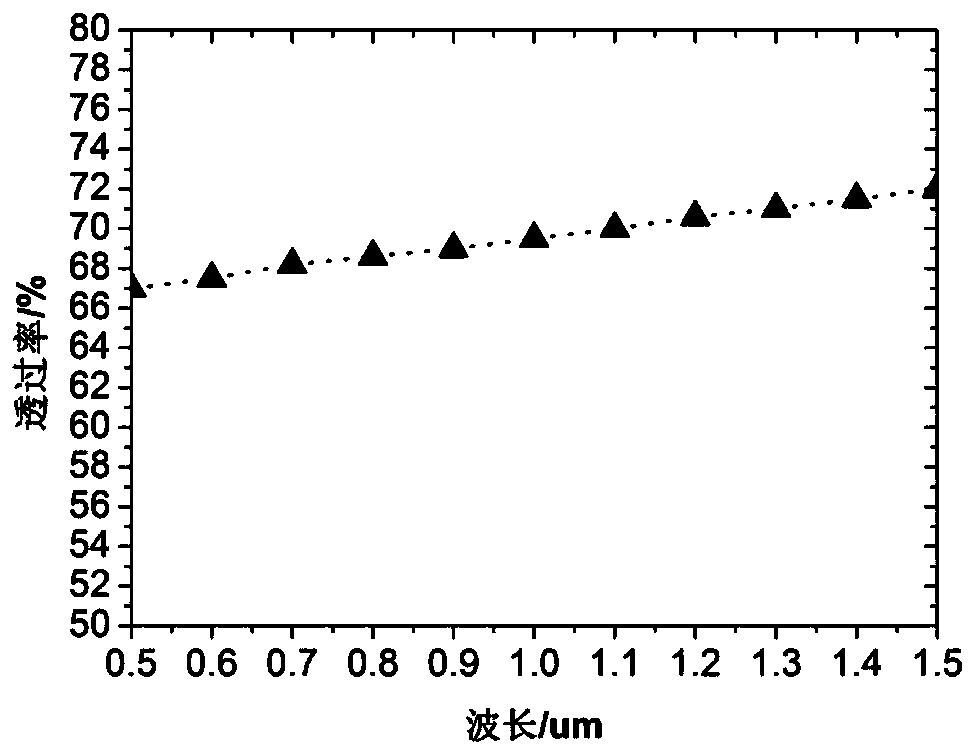

Embodiment 3

[0055] A preparation of Gd 2 Zr 2 o 7 The method for transparent ceramics is characterized in that it comprises the following steps:

[0056] Step 1: Weigh Gd 2 o 3 , ZrO 2 A total of 50 grams of raw materials, with YF 3 The powder is a sintering aid and is reserved for use. in:

[0057] The Gd 2 o 3 , ZrO 2 The masses of are respectively 29.75 grams and 20.25 grams;

[0058] The YF 3 The mass of powder is Gd 2 o 3 , ZrO 2 0.5% (ie 0.25 grams) of the total mass of the powder;

[0059] Step 2: Mix the above three powders, pour them into a nylon tank, add absolute ethanol, and perform ball milling to obtain a slurry. in:

[0060] The mass ratio of the described absolute ethanol to the mixed powder is 2:1 (i.e. 100 grams);

[0061] The ball mill mixing refers to the method of adopting planetary ball mill treatment, the ball mill speed is controlled at 100r / m, and the ball mill time is 30h.

[0062] Step 3: Making a green body A by dry molding. The specific is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com