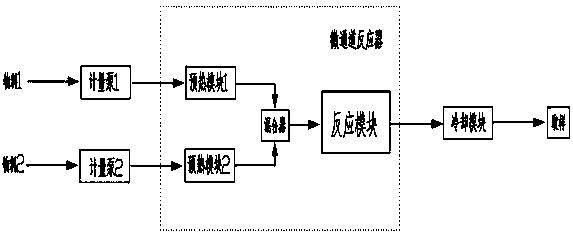

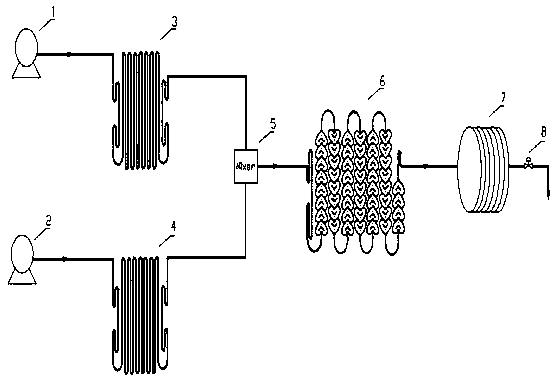

Method for continuous production of 3-methyl-3-penten-2-one in micro-channel reactor

A micro-channel reactor and micro-channel technology are applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., which can solve problems such as corrosion equipment, serious environmental pollution, and high requirements for production equipment, and achieve the goal of avoiding waste water, The effect of reducing waste and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

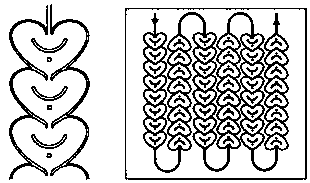

Method used

Image

Examples

Embodiment 1

[0036] Catalyst [Ps-mim]HSO 4 Mix evenly with 5% of the quality of the raw material 2-butanone, adjust the metering pumps respectively, control the molar ratio of 2-butanone and acetaldehyde to be 5:1, and the external heat exchanger controls the preheating module temperature, the temperature of the preheating module is 60°C, and the preheating time is 0.5h. After the preheating is completed, the two raw materials are synchronously passed into the integrated microchannel mixer and mixed evenly. The reaction temperature in the microchannel reactor with an inner diameter of 3 mm is 60 ° C, and the reaction residence time is 15 minutes. The conversion rate of acetaldehyde and the yield of product were analyzed.

[0037]In this example, the conversion rate of acetaldehyde was 97.5%, the yield of 3-methyl-3-penten-2-one was 82.3%, and the purity was 98.8%.

Embodiment 2

[0042] Catalyst [Ps-mim]HSO 4 Mix evenly with 5% of the quality of the raw material 2-butanone, adjust the metering pumps respectively, control the molar ratio of 2-butanone and acetaldehyde to be 10:1, and the external heat exchanger controls the preheating module temperature, the temperature of the preheating module is 65°C, and the preheating time is 0.5h. After the preheating is completed, the two raw materials are synchronously passed into the integrated microchannel mixer and mixed evenly. The reaction temperature in the microchannel reactor with an inner diameter of 1 mm is 65 ° C, and the reaction residence time is 10 minutes. The conversion rate of acetaldehyde and the yield of product were analyzed.

[0043] In this example, the conversion rate of acetaldehyde was 99.2%, the yield of 3-methyl-3-penten-2-one was 85.4%, and the purity was 99.1%.

Embodiment 3

[0048] Catalyst [Ps-mim]HSO 4 Mix evenly with 3% of the mass of the raw material 2-butanone, adjust the metering pumps respectively, control the molar ratio of 2-butanone and acetaldehyde to be 15:1, and the external heat exchanger controls the preheating module temperature, the temperature of the preheating module is 60°C, and the preheating time is 0.5h. After the preheating is completed, the two raw materials are synchronously passed into the integrated microchannel mixer and mixed evenly. The reaction temperature in the microchannel reactor with an inner diameter of 1 mm is 60 ° C, and the reaction residence time is 8 minutes. The conversion rate of acetaldehyde and the yield of product were analyzed.

[0049] In this example, the conversion rate of acetaldehyde was 99.4%, the yield of 3-methyl-3-penten-2-one was 86.6%, and the purity was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com