Matrix resin of cationic electrophoretic coating and preparation method thereof

A technology of cationic electrophoresis and main resin, which is applied in the direction of electrophoretic coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of unknown reactivity and reaction degree, and the effect is not very ideal, so as to achieve good anti-corrosion effect and good appearance. smooth smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

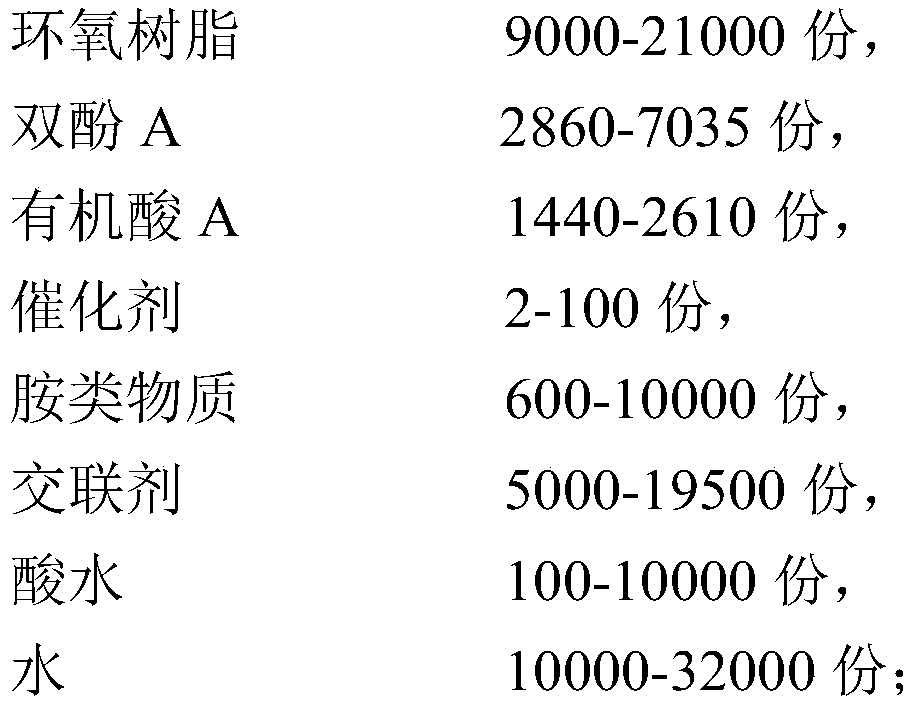

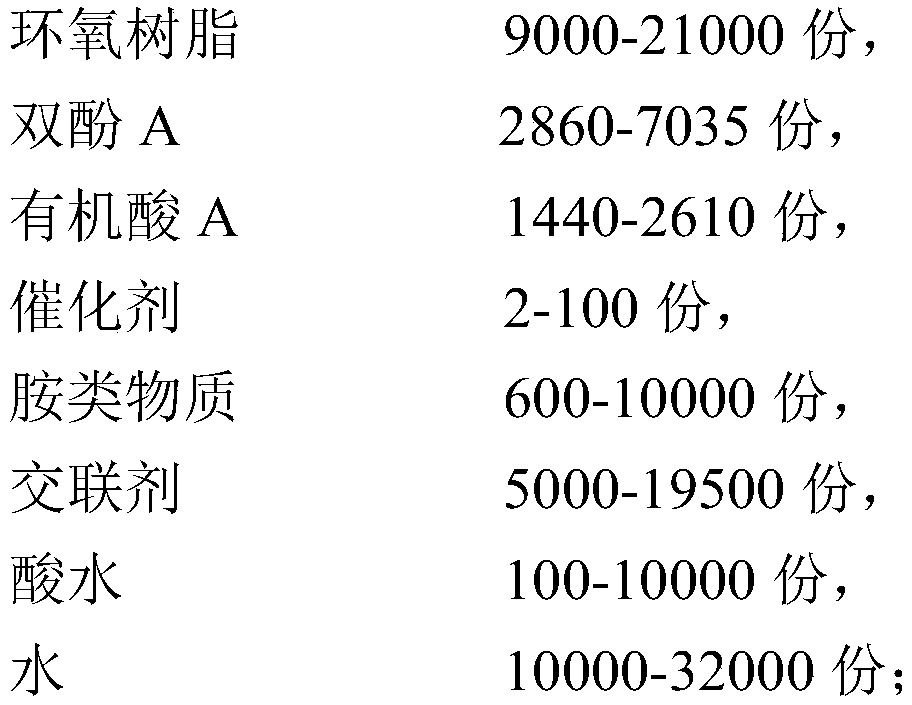

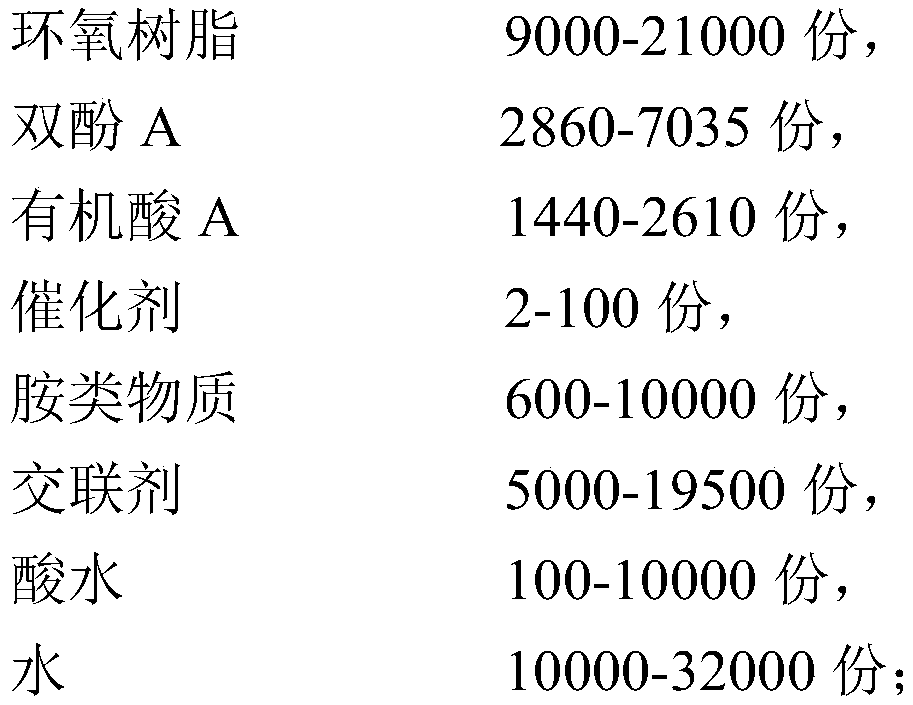

[0054] A possible implementation mode in the present invention is that the preparation method of the above-mentioned cationic electrophoretic coating main resin comprises the following steps:

[0055] Mix 9000-21000 parts of epoxy resin, 2860-7035 parts of bisphenol A, and 1440-2610 parts of organic acid A, heat up to 110-150 ° C, and then add 2-100 parts of catalyst to heat up to 150-180 After ℃, naturally cool down to 110-150 ℃ and keep warm until the epoxy equivalent expands to the required range;

[0056] or,

[0057] Mix 9000-21000 parts of epoxy resin and 2860-7035 parts of bisphenol A, heat up to 110-150 °C to make the material uniform, then add 0.5-40 parts of catalyst and heat up to 150-180 °C, then naturally cool down to 110-150 °C Keep warm; then add 1440-2610 parts of organic acid A, 0.5-60 parts of catalyst, keep warm at 110-150°C until the epoxy equivalent expands to the required range;

[0058] Cool down to 60-100°C, add 600-10000 parts of amine substances, ra...

Embodiment 1

[0074] 11160 parts of NPEL128 epoxy resin, 8.6 parts of bisphenol A3408.6 and 1528.5 parts of isooctanoic acid were put into the reaction bottle, and the temperature was raised to 130°C. , carry out ester etherification epoxy chain extension until the epoxy equivalent increases to 829; cool down to 80°C, add 975.2 parts of diethanolamine, 402.9 parts of dimethylaminopropylamine, raise the temperature to 140°C and keep it for 1h; add crosslinking agent XND-4253 8997.6 parts, the temperature is lowered to 100°C and kept for 0.5h; add pre-prepared acid water, which is prepared by stirring and dissolving 399.7 parts of formic acid and 2557 parts of pure water, and then slowly add 17700 parts of pure water to emulsify and emulsify After stirring evenly, the main resin of the cationic electrophoretic coating is obtained.

Embodiment 2

[0076] Put 11160 parts of NPEL128 epoxy resin and 8.6 parts of bisphenol A340 into the reaction bottle, heat up to 130°C, and after the materials are uniform, add 20 parts of triphenylphosphine and heat up to 160°C, then naturally cool down to 130°C and keep warm for ester etherification Epoxy chain extension until the epoxy equivalent increases to 490; add 1528.5 parts of isooctanoic acid, then add 10 parts of triphenylphosphine, and continue to keep warm at 130 degrees until the epoxy equivalent increases to 829. Then lower the temperature to 80°C and add 975.2 parts of diethanolamine and 402.9 parts of dimethylaminopropylamine. Raise the temperature to 140°C for 1 hour; add 200 parts of anti-cratering agent BYK G-24743 and 8997.6 parts of cross-linking agent XND-4253 and lower the temperature to 100°C Keep warm for 0.5h; add pre-prepared acid water, the acid water is prepared by stirring and dissolving 399.7 parts of formic acid and 2557 parts of pure water, after stirring e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com