Medicine dropping device for ophthalmology

A technology of dropping medicine and ophthalmology, which is applied in ophthalmic surgery, ophthalmic treatment, eye mask, etc., and can solve problems such as eye drops failing to reach the eye, eye drops waste, infection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

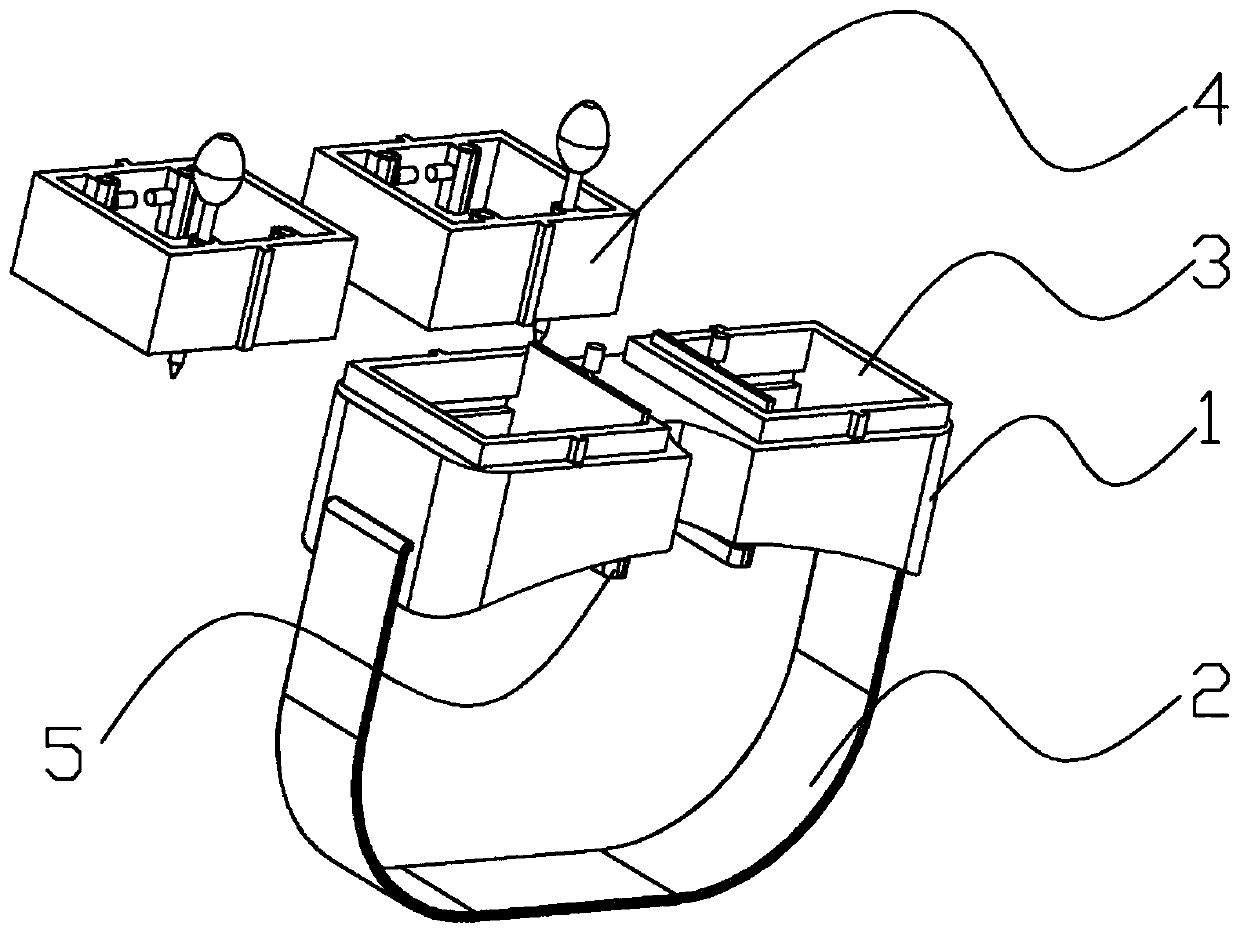

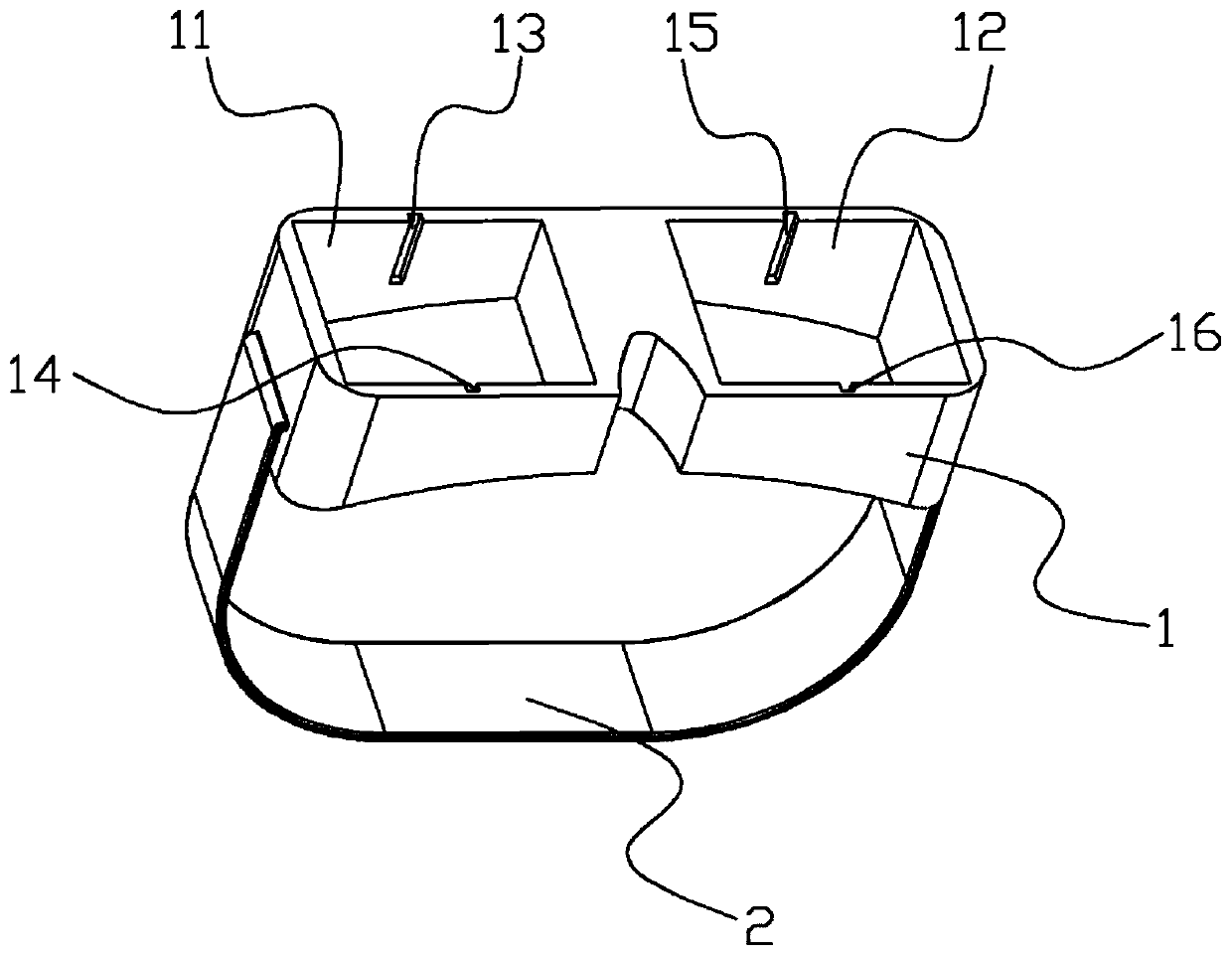

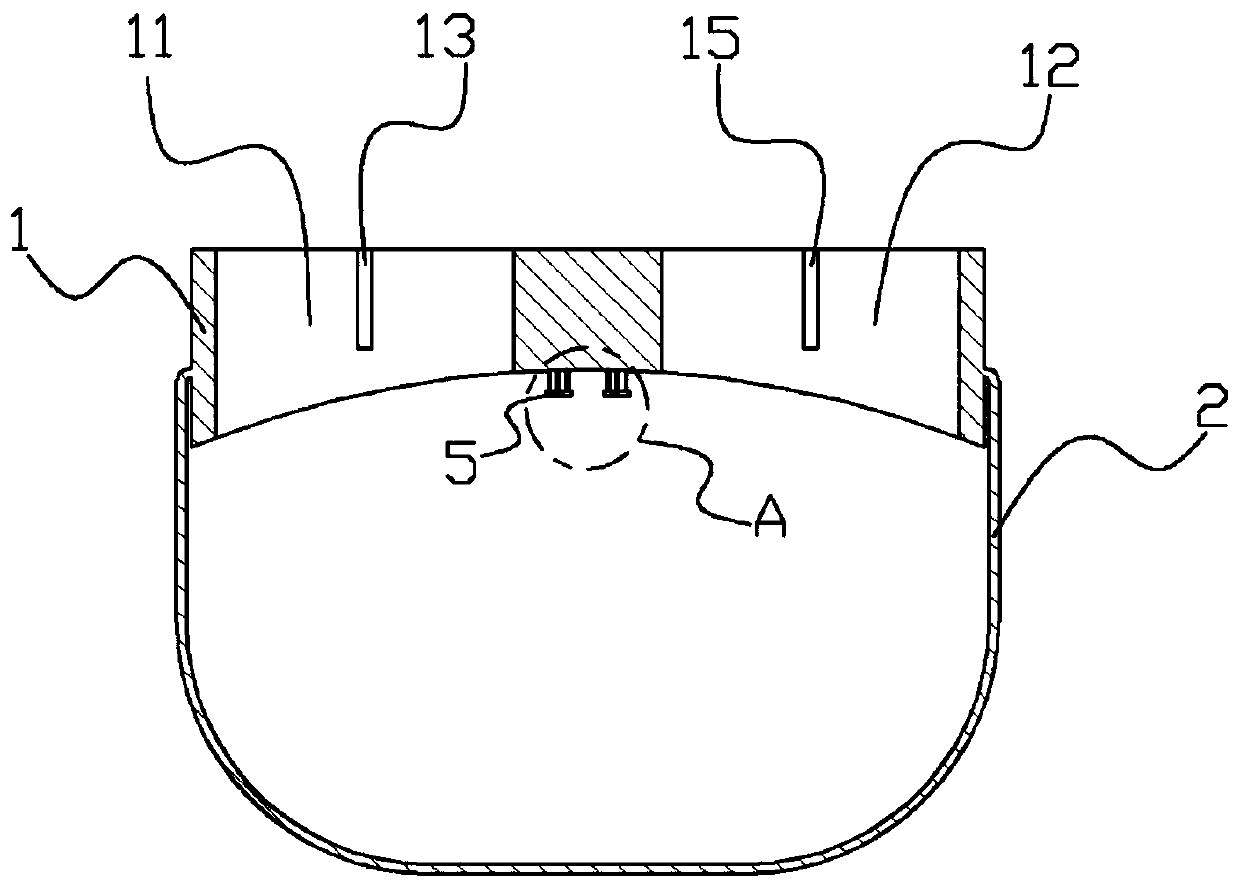

[0041] The following is attached Figure 1-7 The present invention is described in further detail.

[0042] A medicine dropping device for ophthalmology, such as figure 1 and figure 2 As shown, it includes an eye mask body 1, a binding belt 2, two cleaning parts 3, two dripping parts 4, and a lacrimal sac squeezing part 5. The first installation groove 11 and the second installation groove 12, the first installation groove 11 and the second installation groove 12 are symmetrically arranged on the left and right, and the front and rear sides of the first installation groove 11 are respectively provided with the first interlocking groove 13 and The second interlocking groove 14, the front and rear sides in the second mounting groove 12 are respectively provided with the third interlocking groove 15 and the fourth interlocking groove 16, the first interlocking groove 13, the second interlocking groove 14, The third embedding groove 15 and the fourth embedding groove 16 are no...

Embodiment 2

[0055] The difference from Example 1 is that the outside of the glass tube 461 is coated with an anti-slip layer, and the preparation method of the anti-slip layer is:

[0056] Get the following raw materials of each component by weight for later use: 28 parts of water-based acrylate emulsion, 18 parts of water, 11 parts of acrylic polyurethane resin, 1 part of nano silicon dioxide, 37 parts of thermoplastic polyurethane elastomer powder, 2 parts of triethanolamine, Malay 5 parts of acid resin, 9 parts of silicone acrylic emulsion and 7 parts of quartz powder.

[0057] S1. Prefabricated organic solvent: mix water-based acrylate emulsion, acrylic urethane resin, maleic acid resin, water, triethanolamine, and silicon-acrylic emulsion, heat to 65°C, stir evenly, and keep warm for 2 hours;

[0058] S2. Preparation of anti-slip coating: add nano-silica, quartz powder and thermoplastic polyurethane elastomer powder to the organic solvent in S1 in sequence, after stirring evenly, hea...

Embodiment 3

[0064] The difference from Example 2 is that the formula specific gravity of the anti-skid layer is modified, and the modified preparation method is:

[0065] Get the following components by weight for subsequent use: 35 parts of water-based acrylate emulsion, 25 parts of water, 12 parts of acrylic polyurethane resin, 4 parts of nano silicon dioxide, 44 parts of thermoplastic polyurethane elastomer powder, 4 parts of triethanolamine, Malay 8 parts of acid resin, 13 parts of silicone acrylic emulsion and 8 parts of quartz powder.

[0066] S1. Prefabricated organic solvent: mix water-based acrylate emulsion, acrylic urethane resin, maleic acid resin, water, triethanolamine, and silicon-acrylic emulsion, heat to 65°C, stir evenly, and keep warm for 2 hours;

[0067] S2. Preparation of anti-slip coating: add nano-silica, quartz powder and thermoplastic polyurethane elastomer powder to the organic solvent in S1 in sequence, after stirring evenly, heat the temperature to 70° C. and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com